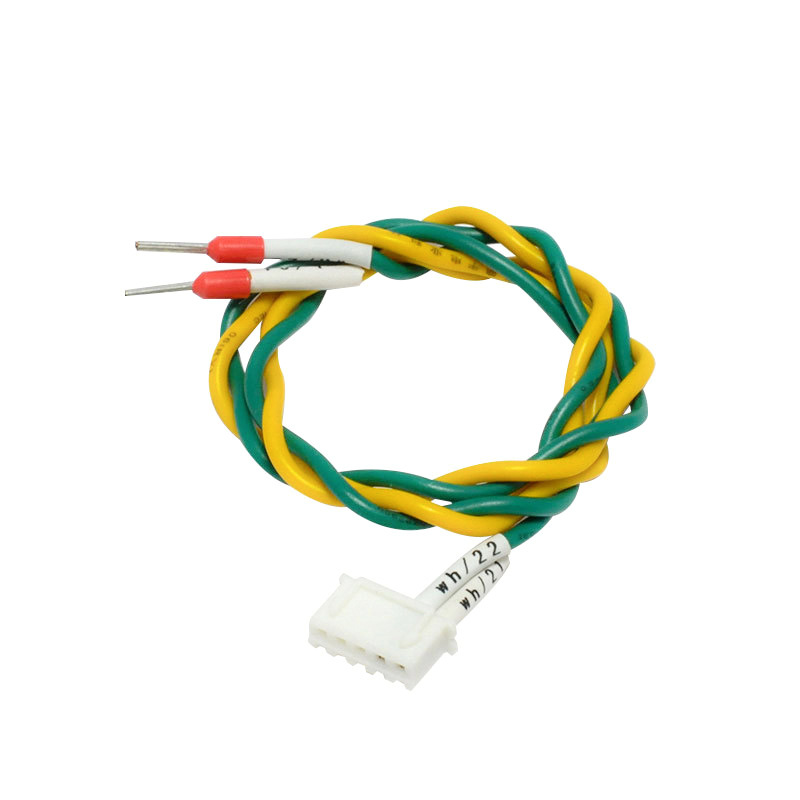

Automobile Wire Harness

Why Choose Us?

KABOLUX has an extensive track record in the automotive sector, with a deep understanding of automotive wire harness design and manufacturing standards.

We offer fully customized solutions, ensuring our products meet the unique specifications of different vehicle models and applications.

Leveraging cutting-edge equipment and a stringent quality control framework, we deliver automotive wire harnesses that are both high – performing and dependable.

International standard

Dimensional Specifications:

Material Specifications:

Fixing Process Specifications:

- Fixing Point Layout and Spacing:

- For low-voltage body harnesses, the fixing point spacing should be ≤400mm, with a distance from moving parts of ≥30mm and a distance from heat sources of ≥100mm.

- For high-voltage power harnesses, the fixing point spacing should be ≤300mm, with a distance from moving parts of ≥50mm and a distance from heat sources of ≥200mm.

- For chassis harnesses, the fixing point spacing should be ≤350mm, with a distance from moving parts of ≥20mm and a distance from heat sources of ≥150mm.

- Tie Wrap Operations:

- The remaining length of the tie wrap end should be ≤3mm, with a tilt angle of ≤15°.

- The clamping force for low-voltage harnesses is 20N-40N, and for high-voltage harnesses, it is 50N-80N.

Product Benefits

Our automotive wire harnesses are crafted from premium materials, guaranteeing superior electrical and mechanical performance.

They are rigorously tested across electrical, mechanical, and environmental parameters to ensure unwavering performance in diverse conditions.

Additionally, these harnesses are designed with robust electromagnetic compatibility, minimizing interference with other automotive electronic systems and ensuring seamless vehicle operation.

Full - Chain Technical Capability:

Cost - Control Advantage:

Scale – based Procurement Agreements: We secure copper materials at costs 12% – 18% lower than market rates (offering price – volatility hedging solutions).

Modular Design: This approach minimizes material waste and optimizes overall costs by up to 25%.

Quality Assurance System:

Stage |

Control Standard |

Certification Support |

|---|---|---|

|

Raw Materials |

Spectral analysis + batch traceability |

UL, RoHS, REACH |

|

Production |

AOI visual inspection + real - time SPC monitoring |

IATF 16949, AS9100D |

|

Final Testing |

30kV withstand voltage + eye - diagram signal integrity analysis |

ISO 6469 - 3 (short - circuit safety) |

Product Categories

KABOLUX’s automotive wire harness product line ranges from engine, body, and chassis harnesses to interior ones.

These harnesses ensure precise signal transmission for engine performance, integrate electrical systems for driving comfort, enhance chassis stability and safety, and offer reliable connections for an enhanced in – cabin experience.

New Energy Vehicle Wire Harness Connectors

Automotive Headlight Wire Harness

Automotive Electronic Rearview Mirror Connector Harness

Automotive ECU Connector Harness

High - Voltage Wire Harness for New Energy Vehicles

Automotive Fuse Holder Connector Harness

Applications and Specifications

Power System Harnesses

Engine Harness / Transmission Harness / Chassis Harness

Body System Harnesses

Instrument Panel Harness / Door Harness / Seat Harness / Lighting System Harness / Safety System Harness

Information and Entertainment System Harnesses

Audio System Harness / Navigation System Harness / In – vehicle Communication System Harness

Other Harnesses

Power Distribution Harness / Ground Harness / CAN Bus Harness