Home Appliance Wiring Harness

Why Choose Us?

KABOLUX provides you with high quality wiring harness solutions to meet the unique needs of all types of home appliances with years of experience in researching and producing wiring harnesses for home appliances, a professional technical team, and a strict quality control system throughout the entire process.

Product Advantage

High Safety and Reliability

Our home appliance wiring harnesses use high - quality materials and advanced processes to ensure excellent insulation and stable connections, preventing electrical issues for reliable user protection.

Good Compatibility

Our wiring harnesses are designed to perfectly match various home appliance electrical systems, ensuring smooth signal and power transmission for optimal performance.

Long Service Life

Durable materials and advanced techniques enhance mechanical strength and environmental resistance, allowing the harnesses to withstand repeated stresses for extended use.

Energy Efficiency

Our harnesses minimize transmission energy losses, improving appliance efficiency and helping users save energy and costs.

Product Categories

Sweeper electronic cable

4K LCD TV FPC cable

XH254 PH2.0 JC25 Dual Head with Wire

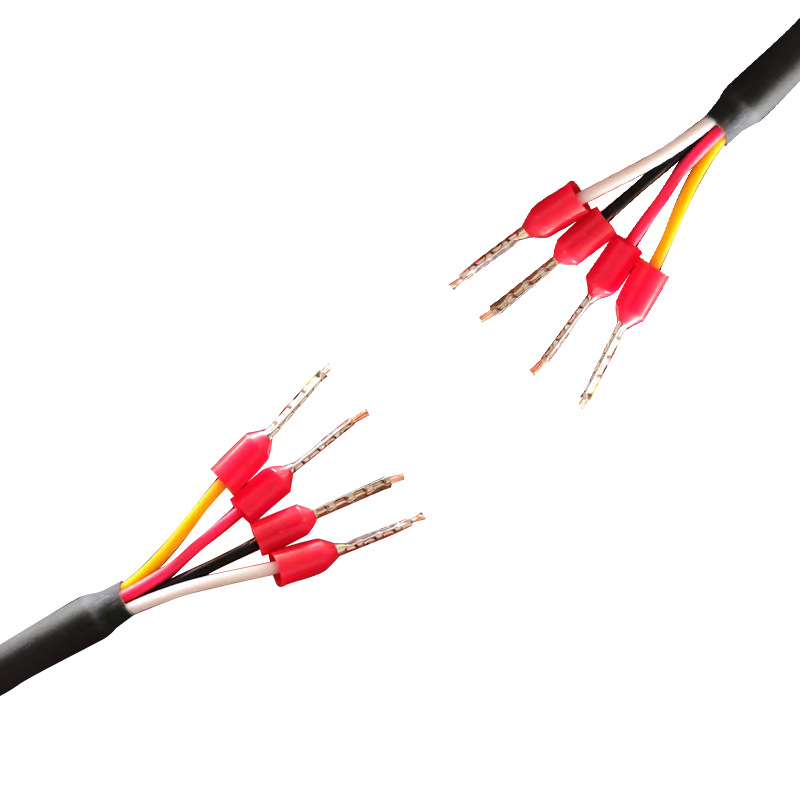

Quick-connect wiring inside appliances

2.54 Terminal Wire Harness

Smart Home Appliance Motor Power Harness

Product Specification Requirements

1. Electrical Performance

2. Mechanical Durability

3. Environmental Resistance

4. Fire Resistance

5. Electromagnetic Compatibility (EMC)

6. Connectors and Terminations

7. Standardization and Documentation

8. Testing and Validation

Application Scenarios