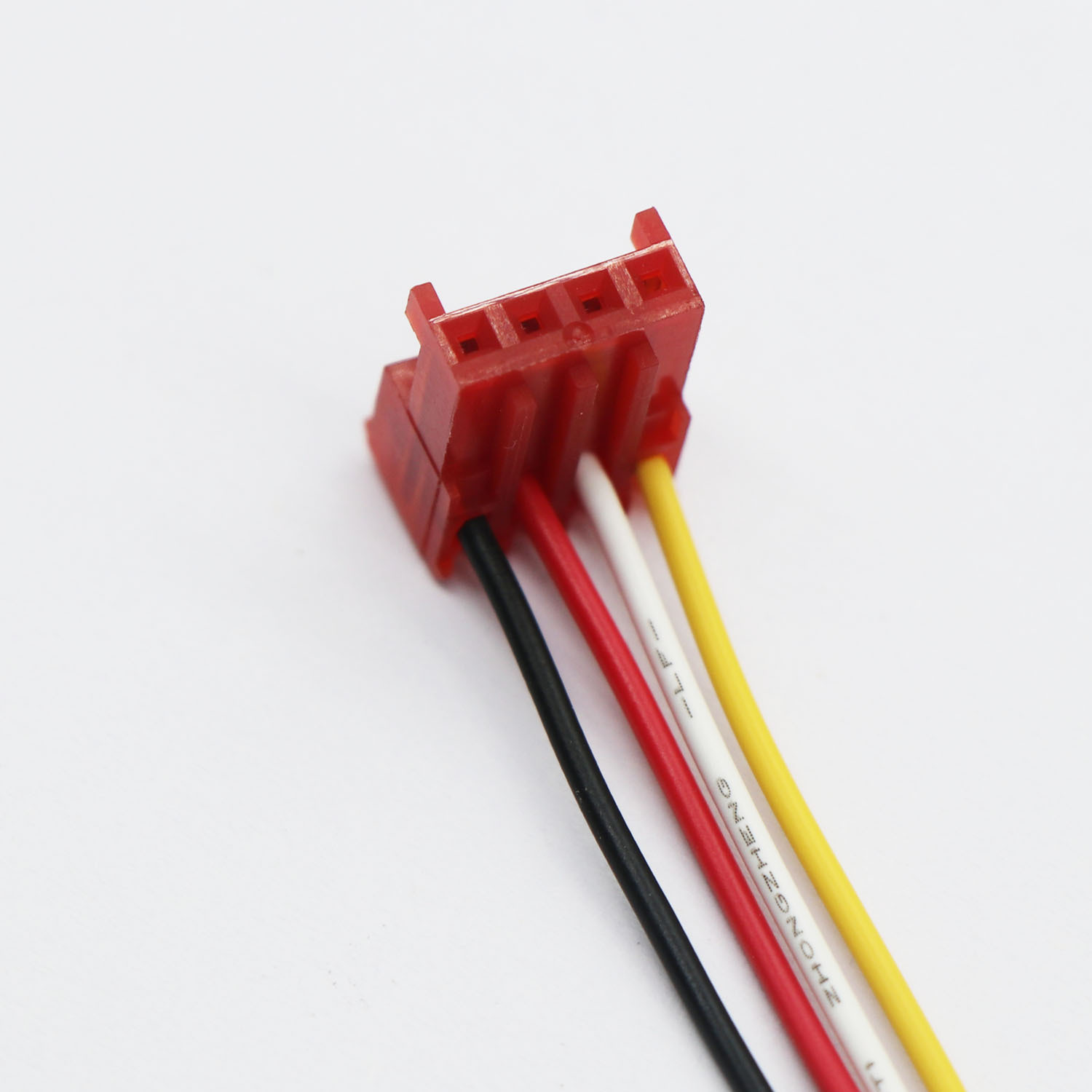

Robot Wiring Harness

Why Choose Us?

As a seller, we stand out with top-tier quality and innovative designs.

Our commitment to meeting diverse customer needs ensures that our solutions are both customized and reliable.

By partnering with us, you gain access to cutting-edge technology and a streamlined process that guarantees precision and efficiency.

Let’s future-proof your automation needs together!

Product Classification and Technical Features

Classified by Robot Type

Type |

Key Features |

Typical Applications |

|---|---|---|

|

Industrial Robot Wiring Harness |

Oil-resistant TPU sheath, supports EtherCAT protocol (latency <1μs) |

Automotive body welding, machine tool control |

|

Collaborative Robot Wiring Harness |

Super flexible silicone jacket, bending radius ≤5D (outer diameter) |

Precision assembly, medical surgery |

|

Special-purpose Robot Wiring Harness |

Armored and explosion-proof design, temperature-resistant from -40°C to 150°C |

Explosion-proof factories, nuclear power plants |

Classified by Function

Product Advantages

Lightweight Design

Using lightweight materials reduces robots' extra load, boosting their operational efficiency and energy - saving performance.

Superior Flexibility & Durability

Our robot wiring harnesses use top - notch flexible cables and robust connectors, enduring up to 10 million cycles of bending and torsion for long - term stable robot operation.

Great Electromagnetic Compatibility

With advanced shielding tech like aluminum foil + tinned copper mesh dual - layer shielding, the harnesses effectively reduce electromagnetic interference for accurate signal transmission and stable robot control.

High - Temp Resistance & Environmental Adaptability

Made from special high - temp resistant materials, our harnesses function well in 125°C heat, meeting complex environmental demands.

Application Scenarios

Industrial Robot Wiring Harness

Service Robot Wiring Harness

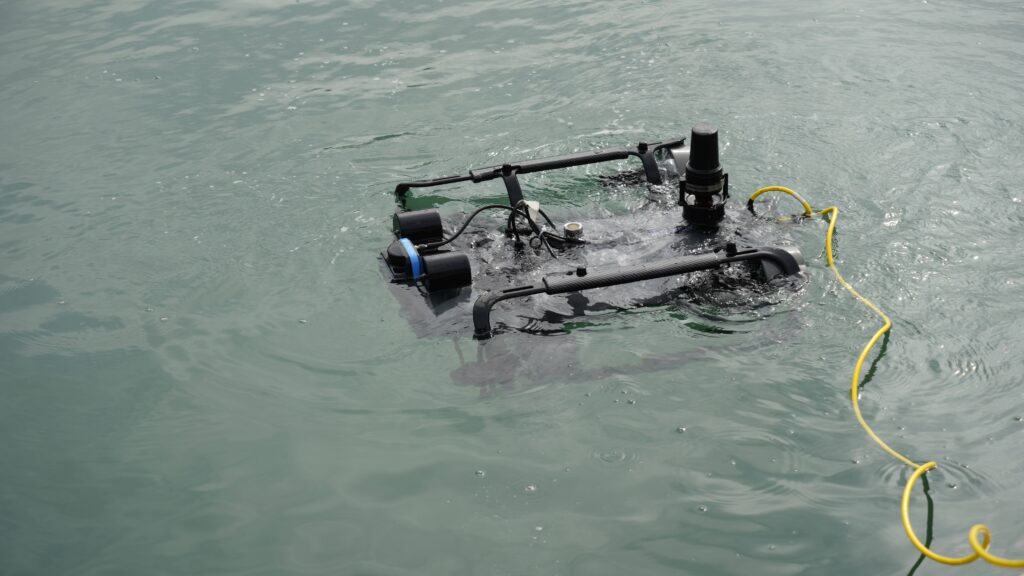

Special - Purpose Robot Wiring Harness

Product Categories

Intelligent ai robot multi-core wire harness

Robot main control board connection cable

Sweeper indicator light high temperature connection cable

FFC/PVC Flex Cable Robot Harness

XT60 Terminal Wire Robot Articulated Module