SERVICES

Services Detail

Direct communication is at the heart of our electrical assembly and manufacturing services, ensuring that our solutions are precisely tailored to meet your specific objectives

Manufacturing Are Available Here

- Transparent and straightforward communication ensures clarity and efficiency in our collaboration.

- Our manufacturing-oriented design expertise streamlines the production process for optimal results.

- Continuous design refinement ensures that our products are always at the forefront of innovation and efficiency.

- We offer rapid response solutions, including concurrent engineering and fast-track project options upon request.

- Our comprehensive component cross-referencing resources guarantee compatibility and seamless integration.

- Our adeptness in handling complex projects ensures that even the most intricate challenges are met with expert solutions.

Quality Control System

Kabolux has fully complied with the stringent requirements of both the ISO 9001:2015 and AS9100D Quality Management Systems. We are well-equipped to meet the stringent regulatory demands of the Aerospace, Space, and Defense sectors. Discover more about the industries we proudly serve on our website. Our Quality System is certified to the most current revision of the AS9100 Standard

Environmental Sensitivity

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

100% Satisfaction

Your Kabolux product comes with a comprehensive warranty that covers any defects in materials or craftsmanship for an entire year from the invoice date.

Highly Professional Staff

They typically possess deep knowledge and skills in a specific field or industry, have the ability to solve complex problems, provide expert advice and solutions, and play a key role in the team that can have a significant impact on the success or failure of a project.

We are here to help you

Pre-sales: To assist customers in making educated selections, our dedicated pre-sales staff provides suggestion for alternative matrial amd cost effective recommendations and precise quotations.

Post-sales: We offer dependable after-sales services such as technical assistance and maintenance.

Our dedication to customer satisfaction fosters long-term success and connections.

How Manufec Work

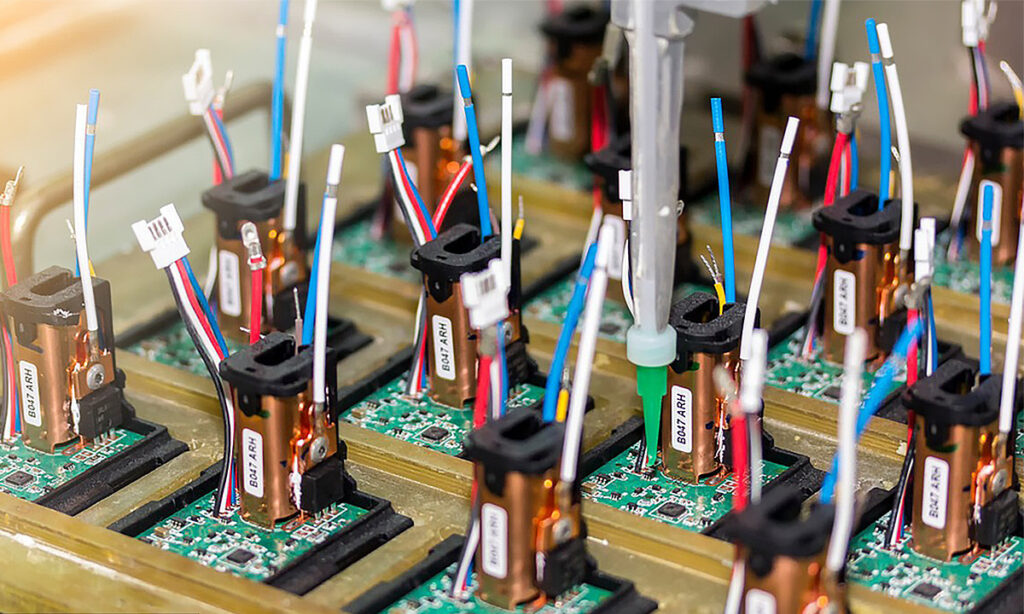

Cable & Wire harness Assemblies

Collaboration for Optimal Wiring Systems

Join forces with us to design the perfect wiring system for your project, ensuring seamless integration and performance.

Reverse-Engineering

Expertise

Utilize our reverse-engineering capabilities to dissect and replicate existing systems, enhancing them with our innovative approach.

Component Review Process

Our meticulous component review process ensures that every part meets the highest quality and compatibility standards.

Quality Assurance Standards

Discover our stringent quality assurance protocols. For a glimpse into our craftsmanship, explore the products showcased on our Samples Page.

Certifications and Memberships

Beyond our USA-based ISO 9001:2015 certification, our Chinese facility also boasts ISO 9001:2015 and ISO 13485:2016 accreditations, reflecting our dedication to excellence. We specialize in cost-effective cable assembly manufacturing, offering custom production, rapid turnaround, and comprehensive testing services, all in adherence to industry benchmarks. Our commitment to environmental responsibility is evident in our ISO 14001:2015 certification. We proudly contribute to the industry's advancement as active members of the Wire Harness Association and BICS.

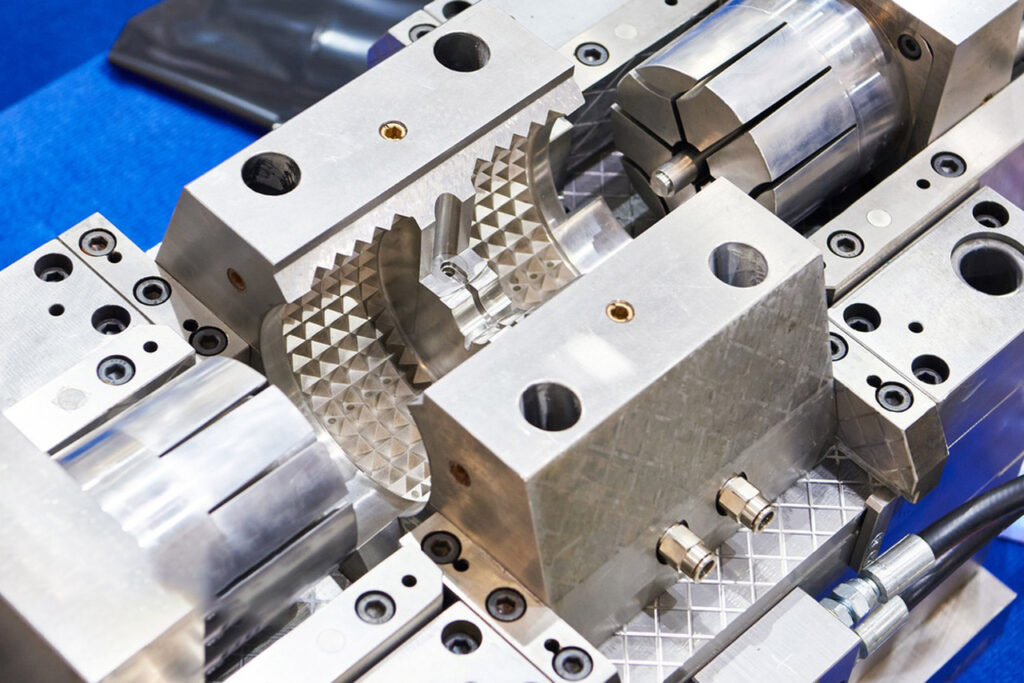

Molding Services

Engage with our experienced engineering team to transform your prototype, from an uncomplicated two-wire harness to an exceptionally complex box build.

*Tailored engineering support that meets your specific needs, offering everything from consultative guidance to comprehensive prototype design.

*Design optimization is an ongoing commitment, ensuring continuous enhancement as your project evolves.

Quick-Turn Cable Assemblies

Global Cable Assembly Network

Kabolux operates multiple cable assembly facilities worldwide to cater to your local needs. For large-scale production of cables and wire harnesses, our in-house manufacturing in China stands ready to deliver.

Local Support and Quick-Turn Manufacturing

Reach out to our local support teams for immediate assistance. We have specialized quick-turn manufacturing processes for urgent orders, as well as for prototype and volume production needs.

Quick-Turn Cable Assemblies & Wire Harness Assemblies

Need it fast? Kabolux offers quick-turn cable assemblies and wire harness assemblies for your urgent projects.

Prototype Cable Assemblies & Wire Harness Assemblies

Our quick-turn manufacturing service enables us to craft prototype cable assemblies and wire harnesses for any application. These prototypes serve as samples and undergo rigorous inspection and testing under our First Article Inspection protocol.

Engineering Excellence in First Article Inspection

Kabolux's dedicated and seasoned engineering team takes charge of the First Article Inspection, ensuring that every aspect of the product, from quotation to shipment, is meticulously documented. During the first article phase, we collaborate closely with our customers to guarantee that all drawings, component specifications, assembly processes, and tooling/test fixtures are recorded for a consistently high-quality product.

Engineering

Our engineering team provides state-of-the-art technical support, guiding our customers through custom product consultation, innovative design solutions, cost-effectiveness analysis, and a suite of other specialized services.

While adhering to our customers’ precise specifications, we uphold a steadfast commitment to industry-benchmark practices and rigorous procedural compliance.

Box Builds

Create Box Builds of Unmatched Complexity.

As a leading contract manufacturing service provider, Kabolux specializes in custom cable assemblies, wire harnesses, and electromechanical assemblies. We cater to a wide range of electromechanical box build projects, from simple control units to complex full device builds. Whether you need full-service manufacturing and assembly or just assembly services, we are equipped to meet your requirements.

Design for Manufacture

Our approach is tailored for efficient production, with concurrent engineering available to expedite your orders.

Electromechanical Box Builds

Electromechanical box builds, also known as electromechanical assemblies or electrical cabinets, are integral to power and signal transmission in electronic equipment. These builds combine cable or wire harness assemblies with enclosures or panels for optimal functionality.

Our Capabilities in Electromechanical Box Builds

Our team expertly manages both full-service manufacturing and assembly-only projects. Our comprehensive solutions cover everything from the production and installation of cable or wire harness assemblies, ensuring a streamlined and efficient production process for our customers.

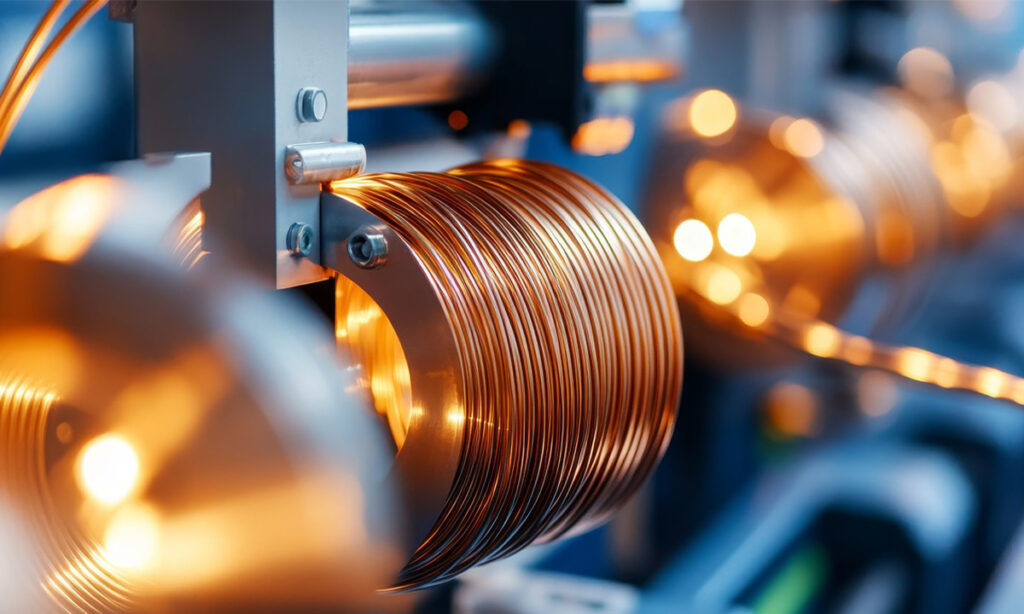

Extruding the components for custom cables—metal conductors, plastics, and other materials—is founded on a straightforward principle. Despite the significant time and labor invested, the mechanics of cable extrusion can be distilled into a few straightforward steps.

Custom Cable Extrusions

We initiate the process with a molten metal, such as copper, and channel it through a specialized extrusion machine, shaping it much like pasta dough is pressed through a mold to take form.

Emerging from the extruder, the molten metal is reborn as a wire rod, a foundational element in all our custom cable extrusions. Our commitment to efficiency ensures some of the quickest production times for custom cable assemblies in the industry.

Post-extrusion, the wire rod may be drawn down to a finer gauge, tailored to the specific conductor size required for your project. This process is ubiquitous in cable manufacturing worldwide, from the power cord of your laptop to the HDMI cable linking your TV to a streaming device.

While a common practice, cable extrusion offers a spectrum of applications. At Kabolux, we specialize in crafting bespoke extruded cables, whether single or multi-conductor, to match the intricacy and function of your cable’s design..

Prototyping

Environmental Sealing and Product Reliability

Trust our expertise to provide an environmental seal for your product, significantly reducing the risk of breakage and extending its lifespan.

Quality Assurance and Product Showcase

Explore our unwavering commitment to quality assurance standards. For a firsthand look at some of the products we've crafted, visit our Samples Page.

Low-Pressure, Low-Temperature Injection Molding Services

We specialize in low-pressure, low-temperature injection molding using polyamide or polyolefin thermoplastic compounds, catering to a diverse array of applications. Our molding capabilities range from standard back shells and basic strain reliefs to the delicate overmolding of circuits that require a gentler process than conventional molding.

Custom Mold Tool Creation

For projects that necessitate a custom mold tool, our Engineering Team is at your service to design a fixture that precisely aligns with your specifications. Leveraging our extensive mold design experience, we can help you sidestep common pitfalls in mold tooling fabrication, ensuring a high-quality end product while keeping your project on schedule and within budget. Additionally, we can procure your mold tool, allowing you to concentrate on other critical aspects of your project.

Potting

Understanding Potting

Potting is a critical process that fortifies electronic assemblies against environmental factors, thereby extending their lifespan and performance. It offers protection from heat, vibration, and moisture, while also serving as an essential electrical insulator. The process predominantly employs two materials: epoxies and silicones.

These materials exhibit robust adhesive qualities, effectively encapsulating the electronic assembly and preventing interactions between conductive components. This encapsulation safeguards the electronics from external influences and environmental variations, thereby bolstering their performance and ensuring enduring reliability.

At Kabolux Cable & Harness, we specialize in potting services for electronic assemblies, utilizing premium epoxies and silicones to shield against heat, shock, vibration, and moisture. Our skilled assemblers meticulously measure, mix, and apply these materials to guarantee a robust and reliable outcome.

Our potting expertise not only safeguards your electronic components but also enhances their operational efficiency. With our swift turnaround times, we ensure that your projects maintain seamless progress.