How to Choose the Right Automotive Wiring Harness for High Temperature Environment?

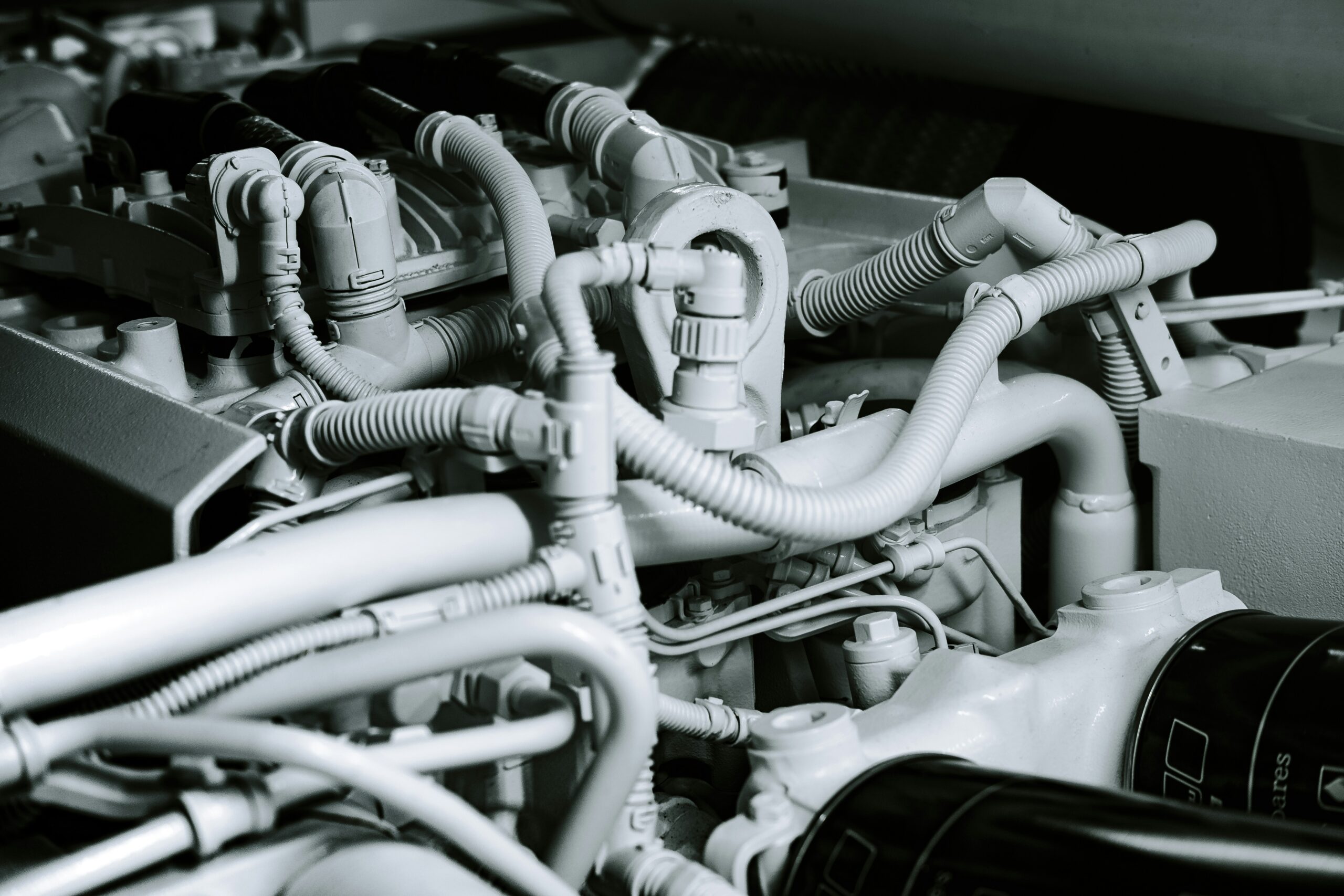

In automotive manufacturing, high-temperature environments are one of the serious challenges facing wiring harnesses.

The temperature in the engine compartment, near the exhaust pipe, new energy battery pack and other areas may exceed 100°C for a long period of time, and even short-term extreme conditions of 200°C or more.

If the material or design of the wiring harness is not up to standard, it may lead to aging of the insulation layer and abnormal signal transmission, or lead to safety accidents such as short-circuit and fire.

Therefore, when choosing an automotive wiring harness suitable for high-temperature environments, it is important to take into account a number of key factors, such as temperature rating, material properties, shielding protection, and industry certifications.

In this article, we will analyse the selection of high temperature wiring harnesses to help you ensure the reliability and safety of your vehicle under extreme working conditions.

预计阅读时间: 10 分钟

Catalogue

Ⅰ.Challenges of High Temperature Environment on Automotive Wiring Harness

1.1 Common high temperature areas and temperature range

1.2 Wiring harness failure mode caused by high temperature

Ⅱ.Core Selection Elements of High Temperature Wiring Harness

2.1 Conductor material selection

2.2 Jackets and Shields

2.3 Connectors and terminals

2.4 Wiring harness layout and heat dissipation design

Ⅲ.Industry Standards and Certifications for High Temperature Wiring Harnesses

3.1 International Standards

3.2 Test Requirements

Ⅳ.Application Scenarios and Selection Recommendations

4.1 Fuel car high temperature area

4.2 Electric Vehicle High Voltage Harness

4.3 Precautions for after-sales modification

Ⅴ.Frequently Asked Questions (FAQ)

Challenges of high temperature environment for automotive wiring harness

1.1 Common high temperature areas and temperature range

- Engine compartment: Long-term exposure to 85°C~150°C, localized (e.g., near the turbocharger) may reach 200°C. -Exhaust pipe/silencer perimeter: radiant heat can reach 200°C~250°C.

- Exhaust pipe/silencer surroundings: Radiant heat up to 200°C~250°C.

- Electric vehicle battery pack/motor: Continuous operating temperature 105°C~150°C, peaks may be higher.

- Brake system: Transient high temperatures during braking (150°C+ for short periods).

1.2 Wiring harness failure modes due to high temperatures

- Insulation aging: Brittleness, cracking, loss of insulating properties.

- Oxidization of conductors: Copper conductors increase in resistance, leading to overheating.

- Loose terminals:Softening of the plastic sheath, resulting in poor contact with the plug.

- Risk of short-circuit: Short-circuit between wires or to ground after insulation failure.

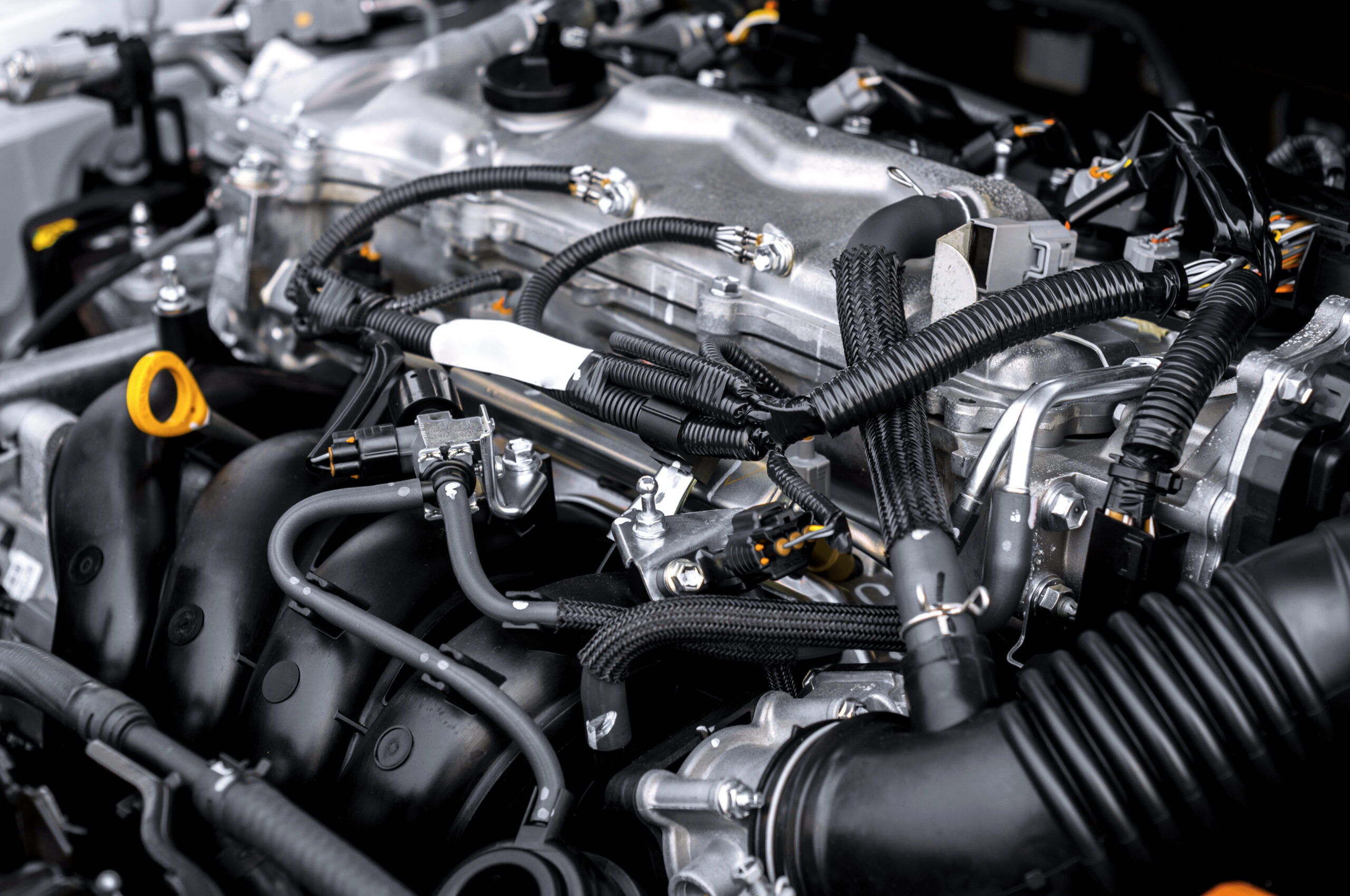

The Core Selection Elements of High-Temperature Wire Harnesses

2.1 Conductor material selection

(1) Conductor materials

·Tinned copper wire (mainstream choice):

- Advantages: Strong oxidation resistance, sulfuration resistance, applicable to 105°C~150°C. Disadvantages: tin layer may melt when exceeding 150°C for a long period of time.

- Disadvantage: Tin layer may melt when exceeding 150°C for a long period of time.

·Nickel-clad copper wire (high-end applications):

- Temperature resistant up to 200°C, extremely corrosion resistant, but high cost.

·Pure copper wire (uncoated):

- Only suitable for temperatures below 90°C, oxidizing at high temperatures, not recommended.

Lightning strikes pose a critical threat to the stable operation of traffic signal systems. The immense energy generated can readily invade through power and signal wire harnesses, causing equipment damage and traffic paralysis. For lightning protection design of wire harnesses, a <strong>three-pronged integrated protection system</strong> encompassing <strong>external direct-strike protection, induced lightning surge suppression, low-resistance grounding, and precision construction</strong> must be established. This forms a solid foundation for ensuring the safe and reliable operation of urban traffic signals.

(2) Insulation Materials

| Material Type | Temperature Resistance Range | Characteristics and Applicable Scenarios |

| PVC | 80°C~105°C | Low cost, but easy to soften at high temperatures, only used in low-temperature areas. |

| XLPE (Cross-linked Polyethylene) | 105°C~150°C | Heat and chemical resistant, commonly used in middle and high-end models. |

| Silicone Rubber | 180°C~250°C | Flexible and resistant to extreme temperatures, but with low mechanical strength. |

| PTFE (Teflon) | 200°C~260°C | Ultra-high temperature, corrosion-resistant, used near turbos. |

| FEP (Fluorinated Ethylene Propylene) | 200°C | More flexible than PTFE, suitable for complex wiring. |

2.2 Jacket and Shield

- Braided Shield: Stainless steel or tinned copper wire braided, high temperature resistant and anti-EMI interference.

- Aluminum foil shielding: Lightweight, but brittle at high temperatures (need to be reinforced with adhesive tape).

- Sheath material:

- TPE (thermoplastic elastomer): Temperature resistant to 125°C, flexible.

- PUR (polyurethane): Oil and abrasion resistant, temperature resistant to 150°C.

- Ceramicized silicone rubber: Forms a ceramic layer flame-retardant in case of fire (fire-fighting requirement scenario).

2.3 Connectors and terminals

- High temperature plastic housing:

- PPS (polyphenylene sulfide): Temperature resistance of 200°C, high strength.

- PA66 (nylon 66): Temperature resistance 130°C~150°C, economical choice.

- Plated finish:

- Gold-plated terminals (oxidation resistant, suitable for signal lines).

- Silver-plated terminals (high conductivity, but easy to vulcanize at high temperature).

2.4 Layout of wire harness and heat dissipation design

- Far away from heat source: Keep ≥50mm distance from exhaust pipe/engine, add heat insulation sleeve if necessary.

- Heat dissipation measures:

- Fixed by metal bracket (use the body to conduct heat).

- Ventilation slot design (to avoid over-tightening of the wire harness).

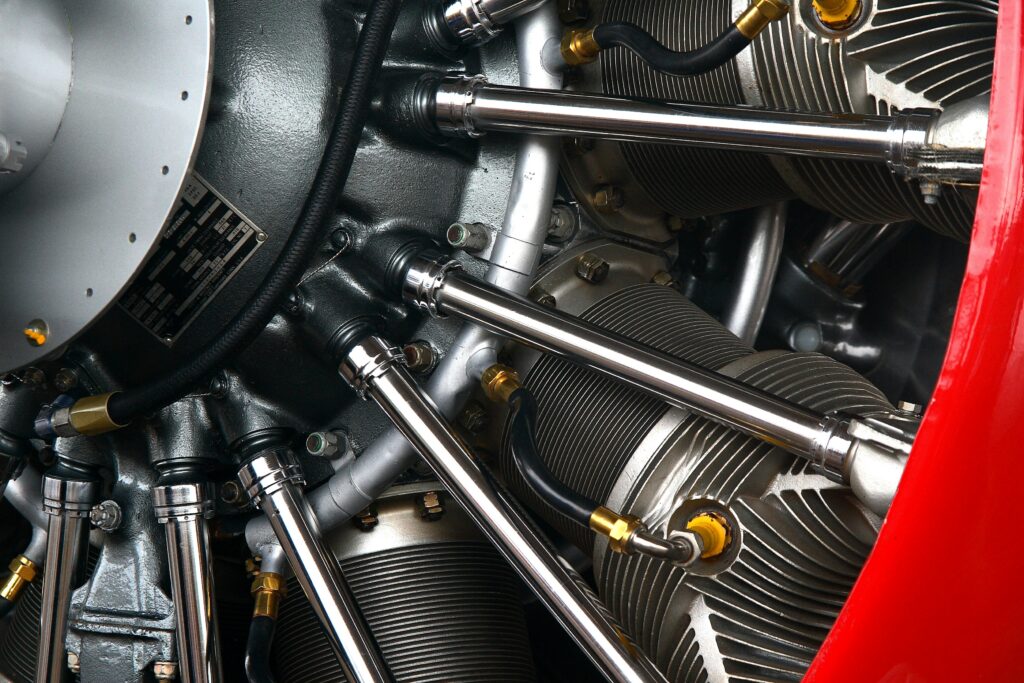

The Industry Standards and Certification of High-Temperature Wiring Harnesses

3.1 International Standards

- ISO 6722: Automotive low-voltage cable standards, temperature resistance level (such as 125 ° C level).

- SAE J1128: SAE standard, covering high-temperature test methods.

- LV 214: Specification for wiring harnesses dedicated to German car companies (e.g. Volkswagen, BMW).

3.2 Test Requirements

Thermal aging test: 3000 hours at 150°C to check whether the insulation layer is cracked.

- Hot and cold shock test: -40°C~150°C cycles to simulate extreme temperature difference.

- Flame retardant test: UL 94 V-0 or IEC 60332-1 (vertical burning).

Application Scenarios and Selection Suggestions

4.1 Fuel car high temperature area

- Engine main harness: XLPE insulation + tinned copper wire + PPS connector.

- Oxygen sensor harness: PTFE insulation + stainless steel braided shield.

4.2 Electric Vehicle High Voltage Harness

- Battery pack interior: Silicone rubber insulation + Nickel-coated copper conductor (resistant to 150°C sustained high temperature).

- Motor 3-phase wires: FEP insulation + silver-plated terminals (reduces contact resistance).

4.3 Precautions for after-sales modification

- Avoid using non-standard wiring harness (e.g. ordinary PVC wire instead of high temperature wire).

- Check the temperature resistance marking of the original wiring harness (e.g. “125°C”).

Frequently Asked Questions (FAQ)

Q1: Is a high temperature wiring harness the more heat resistant the better?

- Not necessarily . Although a higher temperature-resistant grade of harness (e.g., PTFE resistant to 250°C) is more powerful, but the cost may increase by 3 to 5 times. The choice should be based on the actual operating temperature, for example:

- Regular area of the engine compartment (105°C to 150°C): XLPE insulation is sufficient.

- Near exhaust pipe (200°C+): PTFE or silicone rubber is needed.

Q2: How to determine whether the existing wiring harness is resistant to high temperature?

- Method 1: Check the labeling

- The insulation is usually stamped with a temperature resistance rating (e.g. “105°C” “AEX” for cross-linked polyethylene).

- Harnesses conforming to ISO 6722 or LV214 are labeled with a temperature code (e.g. “T3” = 125°C).

- Method 2: Flammability test

- PTFE wire: Does not ignite when exposed to fire, extinguishes when removed from fire.

- PVC wire: Burns with black smoke and pungent odor (not resistant to high temperature).

Q3: How long is the life of high temperature wire harness?

- Nominal temperature: 8~10 years (e.g. 125°C grade harness in 125°C environment).

- Over-temperature use: For every 10°C increase, the life span is reduced by about 50% (e.g., only 3~5 years may remain at 150°C).

Q4: Does high temperature cause wire harness resistance to increase? How to solve it?

- It will . Copper wires have increased resistivity at high temperatures, which may cause overheating. Solution:

- Choose tinned or nickel-plated copper wires (more resistant to oxidation).

- Increase the wire diameter (e.g. upgrade the original design from 1.0mm² to 1.5mm²).

Q5: Is shielding required in high temperature environments? Which type of shielding is better?

- Depends on the situation :

- EMI (Electromagnetic Interference) sensitive areas (e.g. sensor wires): Must be shielded with tinned copper braid.

- Pure high-temperature, non-interference scenarios: shielding can be omitted, with priority given to thermal insulation (e.g., ceramic fiber sleeves).

Q6: How to prevent connectors from failing at high temperatures?

- Suggestions for selection:

- Shell material: PPS (200°C) > PA66 (150°C).

- Terminal plating: Gold plating (oxidation resistance) > Tin plating (low cost).

- Installation Note :

- Avoid direct contact of the connector with heat sources (e.g., fixed on a metal bracket to dissipate heat).

Q7: When replacing high temperature wiring harnesses after sale, can I mix different temperature resistance levels?

- No. It is strictly prohibited! Mixing is strictly prohibited!

- For example, if you replace the original 125°C wiring harness with 90°C PVC wiring, it may work in the short term, but in the long term, it will be short-circuited.

- You must match the original specifications or choose a higher temperature resistance level.

Q8: How to test the actual temperature resistance of the wiring harness?

- Laboratory method :

- Thermal aging test (e.g., 3000 hours at 150°C to check for cracks in the insulation).

- Thermal shock test (-40°C~150°C for 100 cycles).

- Simple method :

- Use hot air gun to locally heat up to the working temperature and observe whether the wire harness becomes soft and deformed.

Q9: How much more expensive is a high-temperature wiring harness than an ordinary wiring harness?

- Cost Comparison (Take 1 meter wire as an example):

| Type | Price Range ($/m) | Applicable Scenarios |

| PVC wire | 1~3 | Low temperature zone in the car (<90°C) |

| XLPE wire | 3~8 | Engine compartment (105°C~150°C) |

| PTFE wire | 15~30 | Near exhaust/turbo |

Q10: Does the high-voltage wiring harness of electric vehicles need a higher temperature resistance level?

- Yes. Reason:

- Battery packs and motors are subjected to constant high temperatures (generally 150°C).

- The heat generated by the wire itself is more significant when high current is passed.

- Recommended solution :

Silicone rubber insulation + nickel-plated conductors and in accordance with ISO 19642 for high-voltage wiring harnesses.

The selection of high-temperature wiring harnesses needs to take into account the actual temperature, cost, life, safety standards, to avoid “over-design” or “cutting corners”.

For critical areas (such as EV high-voltage system, turbocharger periphery), it is recommended to give priority to PTFE or silicone rubber insulation + metal shielding layer solution, and verify the reliability through thermal simulation tests.

Summarize

Selection of high temperature automotive wiring harnesses requires comprehensive consideration of material temperature resistance, mechanical strength, shielding requirements, cost and other factors, and strict adherence to automotive standards. For critical areas (e.g. EV battery packs), it is recommended to prioritize silicone rubber or PTFE insulation + nickel-plated conductors, and verify the reliability through thermal simulation tests.

Leave a Comment