How to choose the right wire harness specification based on current and voltage?

In electrical system design, the selection of wire harness specifications directly affects the performance, safety and reliability of the equipment.

If the wire diameter is too small, it may lead to overheating, excessive voltage drop or even burning; if the insulation level is insufficient, it may lead to the risk of breakdown under high-voltage environment.

Reasonable selection needs to take into account the current carrying capacity, voltage level, environmental factors and industry standards. In this article, we will systematically analyze how to calculate the wire diameter according to the current, determine the insulation requirements according to the voltage, and provide guidelines for selection based on practical application scenarios.

1. Selecting Conductor Size Based on Current (Cross-Sectional Area)

Proper selection of wire cross-sectional area is fundamental to ensuring the safe and stable operation of electrical systems. Current-carrying capacity directly determines the minimum conductor size requirements. Improper selection may lead to conductor overheating, excessive voltage drop, or even fire hazards.

① Current-Carrying Capacity Calculation:

ⅰ. Basic Formulas

● For DC or single-phase AC systems, the current calculation formula is: l=P/V

● For three-phase AC systems, the power factor effect needs to be considered: l=P/(√3 * V * cos(θ))

(I is current (A), P is power (W), V is voltage (V), cosϕ is power factor)

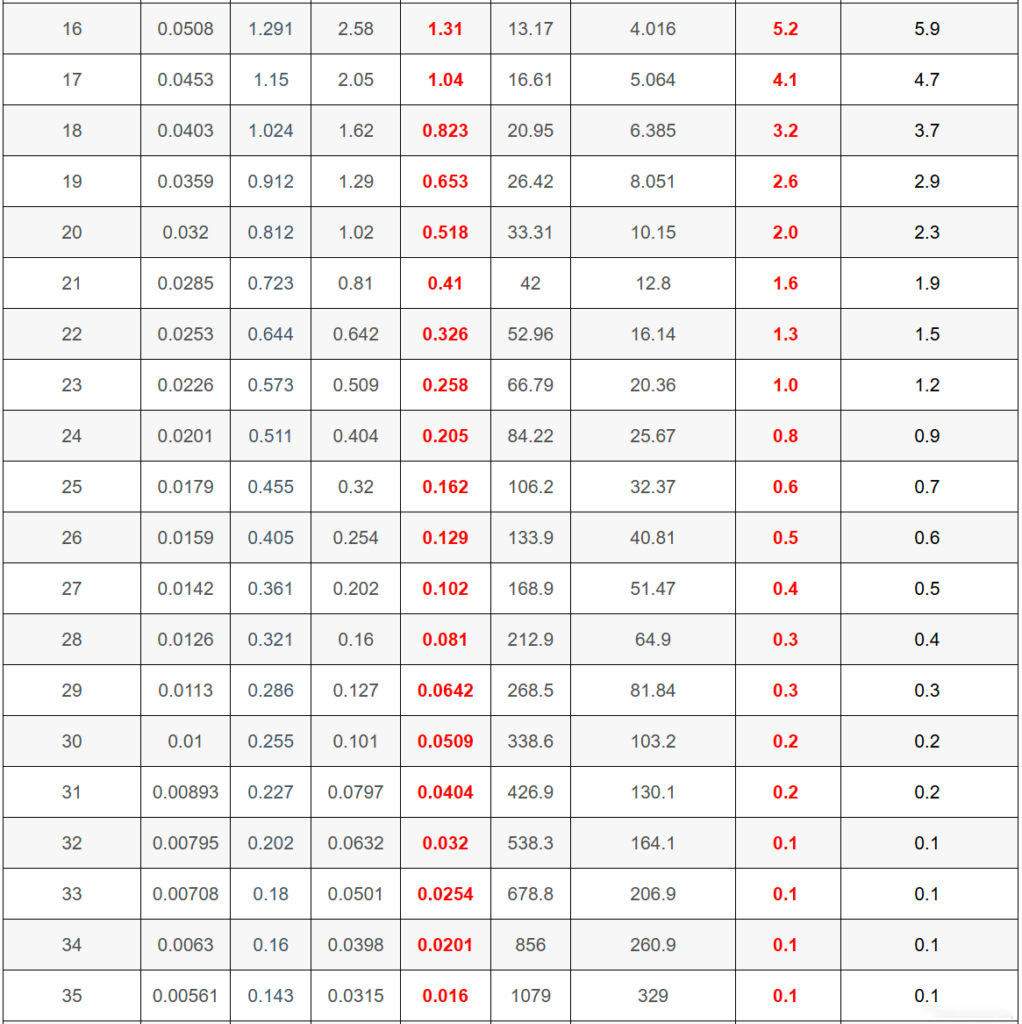

▲ Example : Comparison table of cable current-carrying capacity ▲

ii. Derating Factors

▶ Practical applications require consideration of:

● For every 10°C increase, current rating decreases by ~5%

● Cable tray installation reduces capacity by 15-20% vs. overhead.

● Derating is required for multiple wire bundles in parallel.

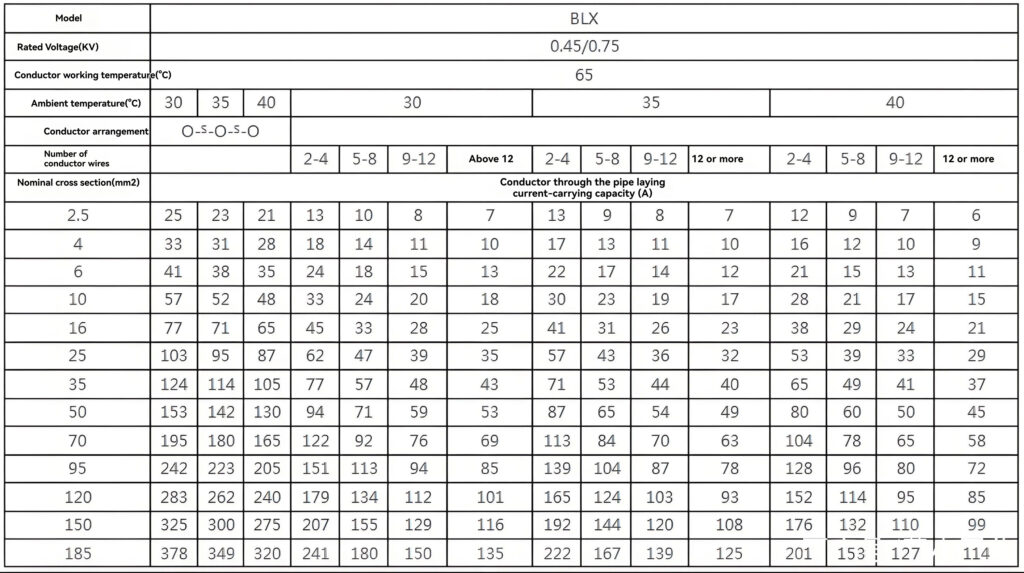

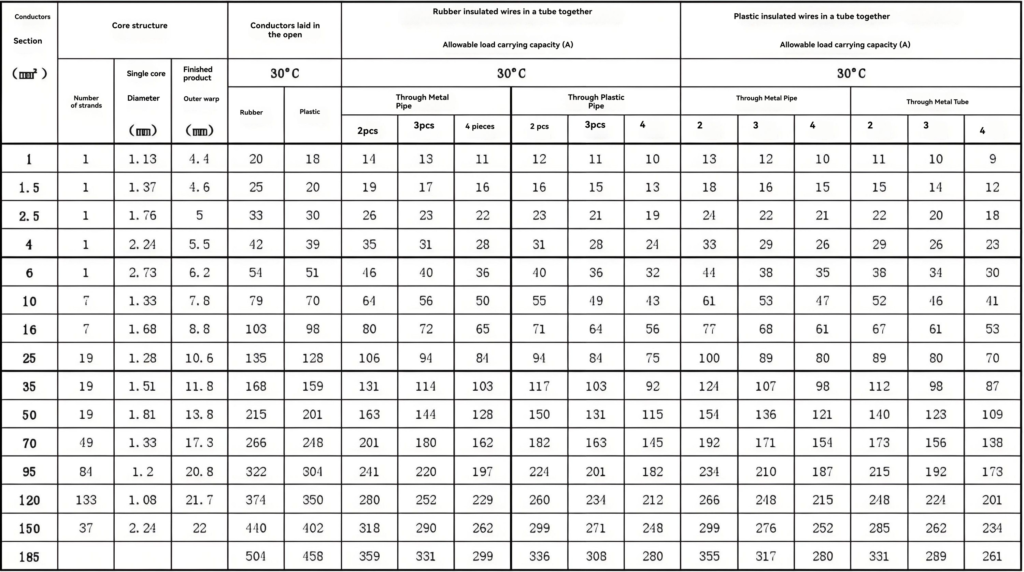

▲ Example : Comparison table of conductor current-carrying capacity ▲

Empirical values for reference:

● Ambient temperature: For every 10°C increase, the current-carrying capacity decreases by about 5%.

● High temperature environments (e.g. engine compartment) need to be derated (e.g. by 20%~30%).

② Conductor Size Selection Criteria:

ⅰ. Low-voltage systems (≤60V):

● Small current (<5A): 0.5~1.5mm² (e.g. sensor signal wire).

● Medium current (5~20A): 1.5~4mm² (e.g. car audio, lighting).

● High current (>20A): ≥6mm² (e.g. battery main cable, need to refer to GB/T 5053).

ⅱ. High-voltage systems (>60V):

● Must meet insulation ratings (e.g. 600V cables for 400V EV systems)

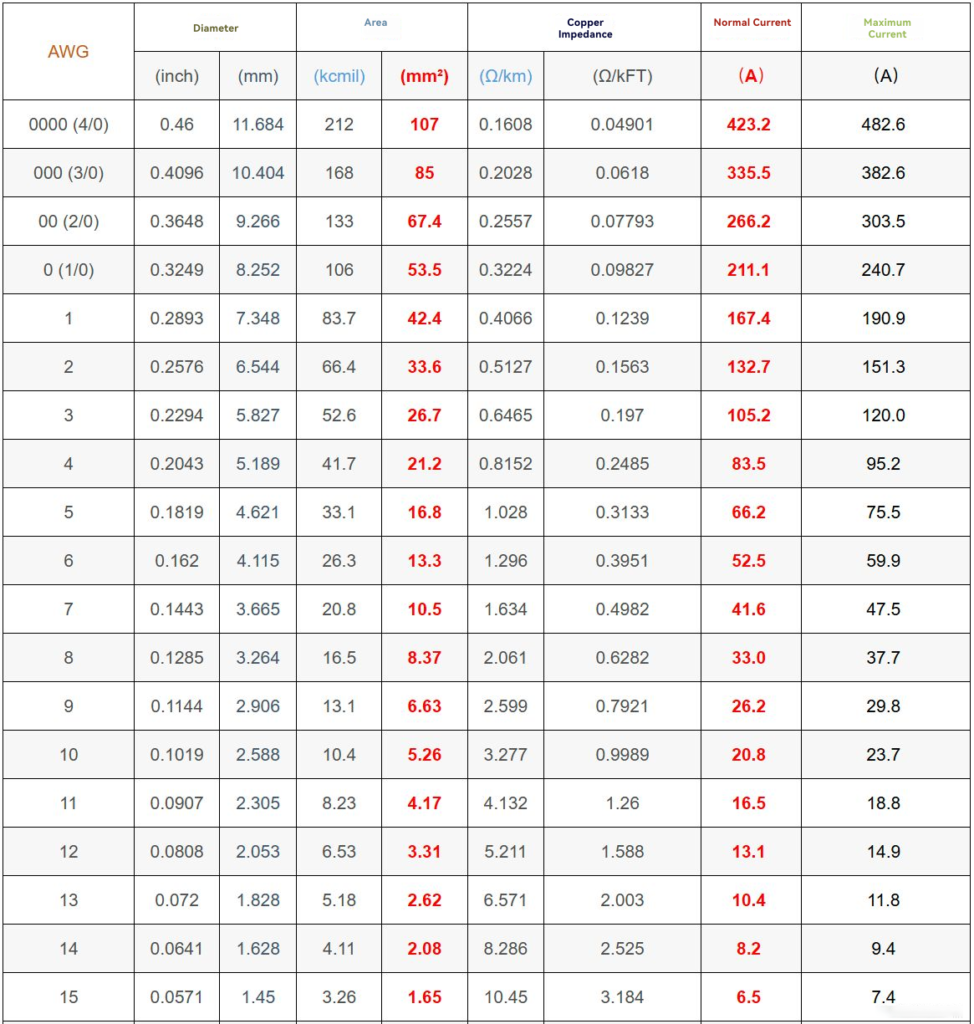

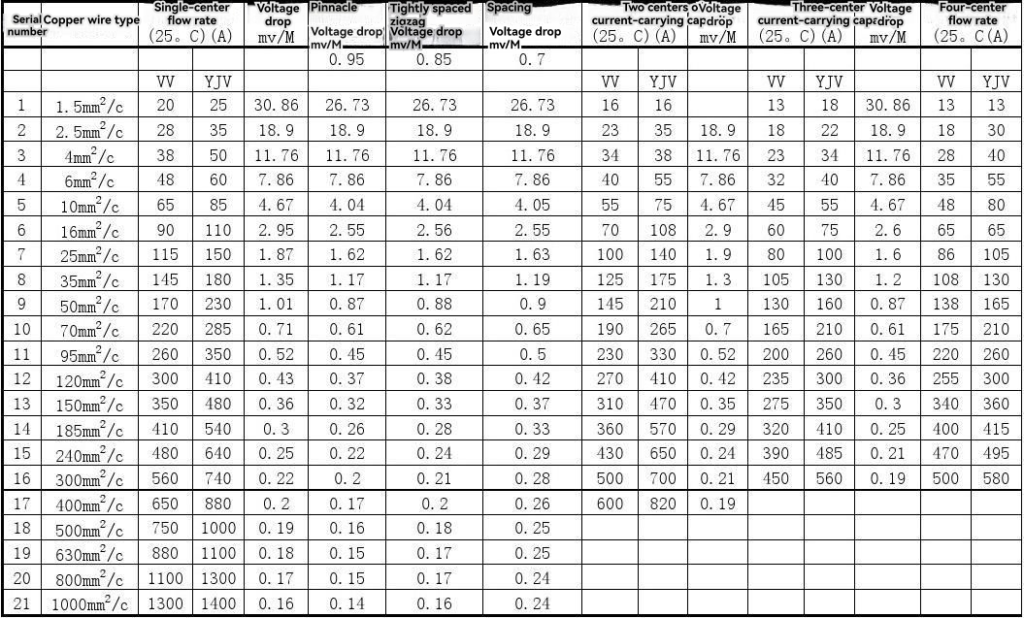

▲ Example : Current Conversion Chart ▲

③ Voltage Drop Verification:

ⅰ. Allowable voltage drop:

● General equipment: ≤3%

● Precision equipment: ≤1%

ⅱ. Calculation formula: ΔU = I × R × L (R: Resistance per unit length (Ω/m); L: Wire length (m))

▶ Optimization measures:

● Upsize conductor gauge

● Minimize cable run length

● Use higher conductivity materials

▲ Example : Voltage drop quick reference table ▲

2. Insulation Rating Selection Based on Voltage

① Insulation Materials & Voltage Ratings

ⅰ. PVC (Polyvinyl Chloride):

● 300-600V rating, temperature ≤105°C

● Applications: Household appliances/LV control wires

▲ PVC hose ▲

ⅱ. XLPE (Cross-linked Polyethylene):

● 600V-1kV rating, 125°C resistant

● Applications: Industrial equipment/PV systems

▲ XLPE hose ▲

ⅲ. Silicone Rubber :

● Voltage Rating: 1kV~3kV

● Features: High temperature resistance (>180℃), excellent flexibility

● Recommended Uses: NEV high-voltage harnesses, high-temperature environments (e.g. motor winding leads)

▲ Slicone Rubber hose ▲

ⅳ. PTFE (Polytetrafluoroethylene) :

● Rated Voltage: 3kV~10kV

● Technical Characteristics: High dielectric strength, chemical resistance, but costly

● Typical Applications: Special fields like aerospace, medical equipment

▲ PTFE ▲

② Insulation Thickness Requirements

| Voltage (V) | Min Thickness (mm) | Standard |

| ≤300 | 0.4~0.6 | UL 1581 |

| >1000 | ≥1.5 | IEC 60502 |

③ HV System Requirements (>1kV)

▶ For high voltage applications such as electric vehicles, energy storage systems, etc. (typically 400V~800V), additional considerations are required:

● Double insulation or shielding: to prevent high voltage electric fields from interfering with signal lines.

● Partial discharge test: to ensure that the insulation is free from microscopic defects (standard: IEC 60885-3).

● Electro-trafficking resistance: to pass the CTI (Relative Leakage Starting Trace Index) test (e.g. ≥600V).

④ Environmental Adaptability Correction

● High-temperature environment: Select high-temperature-resistant materials (e.g., silicone rubber) and increase the insulation thickness by 10% to 20%.

● Humid environment: Use moisture-proof insulation (e.g. cross-linked polyolefin) and avoid water tree phenomenon.

● Chemical corrosive environment: Use PTFE or fluorine rubber insulation.

3. Environmental Factor Adjustments

In electrical system design, the selection of wire harness specifications must consider not only basic current and voltage requirements but also adjustments based on actual operating environments.

Various factors such as temperature, humidity, mechanical stress, and chemical corrosion can affect the performance and lifespan of wire harnesses.

Neglecting environmental factors may lead to premature aging of cables, insulation failure, and even safety hazards.

① Temperature Effects

ⅰ. High-temperature environments (e.g., engine compartments, industrial furnaces):

● Material selection: Standard PVC insulation softens and deforms at high temperatures. Use high-temperature-resistant materials (e.g., silicone rubber or XLPE cross-linked polyethylene, rated up to 180°C).

● Current derating: For every 10°C increase in ambient temperature, the current-carrying capacity of copper conductors decreases by 5%~10% (refer to IEC 60287 standard).

ⅱ. Heat dissipation design: Avoid dense bundling in high-temperature areas. Provide adequate spacing or use metal conduits for heat transfer.

ⅲ. Material brittleness: PVC becomes brittle and cracks below -20°C. Use cold-resistant materials (e.g., TPE thermoplastic elastomer or fluoropolymers).

ⅳ. Flexibility requirements: Maintain harness flexibility in low temperatures to prevent insulation cracking during bending.

② Mechanical Stress

ⅰ. Vibration and bending (e.g., automotive harnesses, robotic joints):

● Cable construction: Use multi-strand fine copper conductors (e.g., Class 5 or 6 flexible cables) to enhance fatigue resistance.

● Protection measures: Add corrugated tubes or spiral sleeves in vibration-prone areas to reduce wear.

● Bend cycle life: Cables in dynamic applications (e.g., drag chains) must withstand ≥1 million bend cycles (refer to ISO 60245).

ⅱ. Tension and compression (e.g., lifting equipment, mining machinery):

● Tensile design: Use cables with Kevlar fibers or steel braiding to prevent breakage.

● Installation: Secure harnesses with clamps or rails to avoid stress concentrations.

③ Chemical and Humidity Effects

ⅰ. Corrosive environments (e.g., chemical plants, coastal areas):

● Protection rating: Use chemical-resistant jackets (e.g., PUR polyurethane or FEP fluoropolymer).

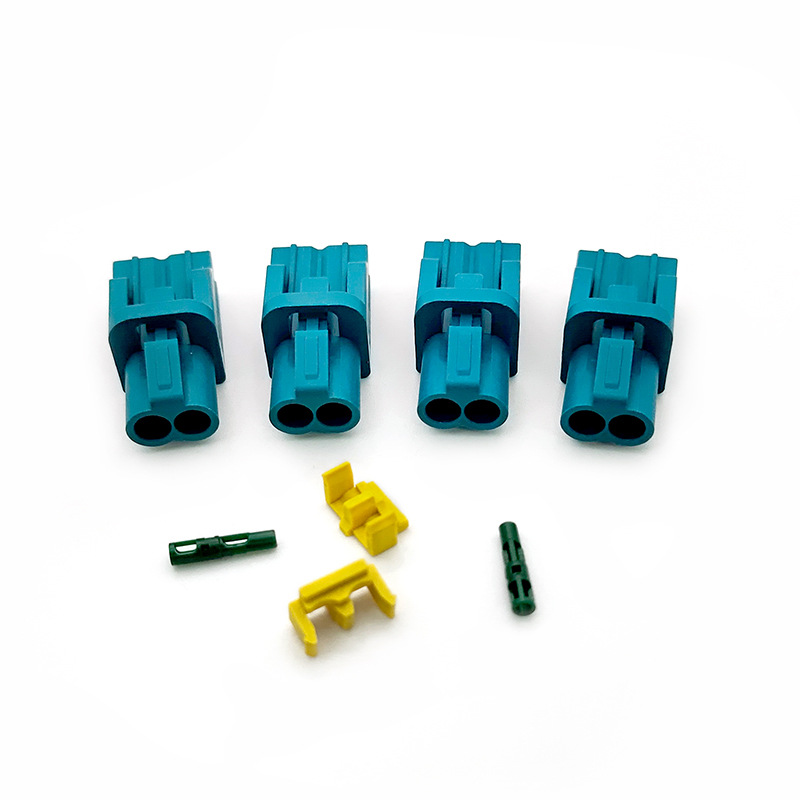

● Sealing requirements: Connectors must meet IP67/IP69K ratings to prevent liquid ingress.

ⅱ. Humid environments (e.g., underwater equipment, outdoor enclosures):

● Moisture protection: Use water-blocking cables (e.g., gel-filled or dual-insulated designs) to prevent oxidation.

● Insulation resistance: Maintain >1MΩ in humid conditions (test standard GB/T 3048.5).

④ Electromagnetic Interference (EMI) Environments

ⅰ. High-EMI scenarios (e.g., near VFDs, communication base stations):

● Shielding: Use twisted-pair cables with foil/braid shielding (e.g., CAT6 or coaxial cables).

● Grounding: Implement single-point grounding for shields to prevent ground loops.

4. Safety Standards and Certifications

In electrical system design, calculating current-carrying capacity and voltage ratings alone is insufficient. Wire harnesses must also comply with industry safety standards and certifications to ensure long-term reliability and prevent safety hazards.

Different application scenarios (e.g., automotive, industrial, consumer electronics) impose strict requirements on wire harness properties such as temperature resistance, flame retardancy, oil resistance, and EMI protection.

① Safety Standards and Certifications

ⅰ. Automotive Industry

● ISO 6722: Specifies basic performance requirements for automotive low-voltage cables, including temperature/oil resistance and bending endurance.

● LV 112-3 (German Standard): Widely used by German OEMs (e.g., VW, BMW) with stricter mechanical/environmental requirements.

● SAE J1128 (US Standard): SAE standard for 12V/24V automotive harnesses.

ⅱ. Industrial Equipment

● UL 1015 (US Standard): For industrial control cabinets/motor wiring, requiring 600V rating and flame retardancy.

● EN 50525 (EU Standard): Covers power/signal cables with emphasis on eco-friendliness and chemical resistance.

ⅲ. Consumer Electronics & Appliances

● UL 2464: For internal wiring (e.g., USB/HDMI cables) requiring Low Smoke Zero Halogen (LSZH) materials.

● IEC 60227: General requirements for PVC-insulated cables (e.g., appliance power cords).

ⅳ. High-Voltage & New Energy Applications

● ISO 19642: EV high-voltage cable standard (>1000V rating + EMI shielding).

● UL 4703: PV system cables requiring UV resistance and thermal cycling endurance.

② Key Performance Certifications

ⅰ. Flame Retardancy Ratings

● UL94 V-0: Vertical burn test (self-extinguishing within 10s, no dripping).

● IEC 60332-1: Single-wire vertical flame test (industrial-grade).

● IEC 60332-3: Bundle cable flame test (e.g., data centers).

ⅱ. Temperature Ratings

● -40℃~105℃ (Standard): PVC/PE insulation for indoor equipment.

● -55℃~150℃ (High-Temp): Silicone/Teflon insulation for engine bays/industrial use.

ⅲ. Environmental Certifications

● RoHS: Restricts hazardous substances (e.g., Pb, Cd) for EU exports.

● REACH: Requires chemical safety assessments for material selection.

③ Certification Markings

ⅰ. Certified cables typically display markings on the jacket, such as:

● UL Listed (US Safety Certification)

● CE (EU Conformity Marking)

● CCC (China Compulsory Certification)

5. Safety Standards and Certifications

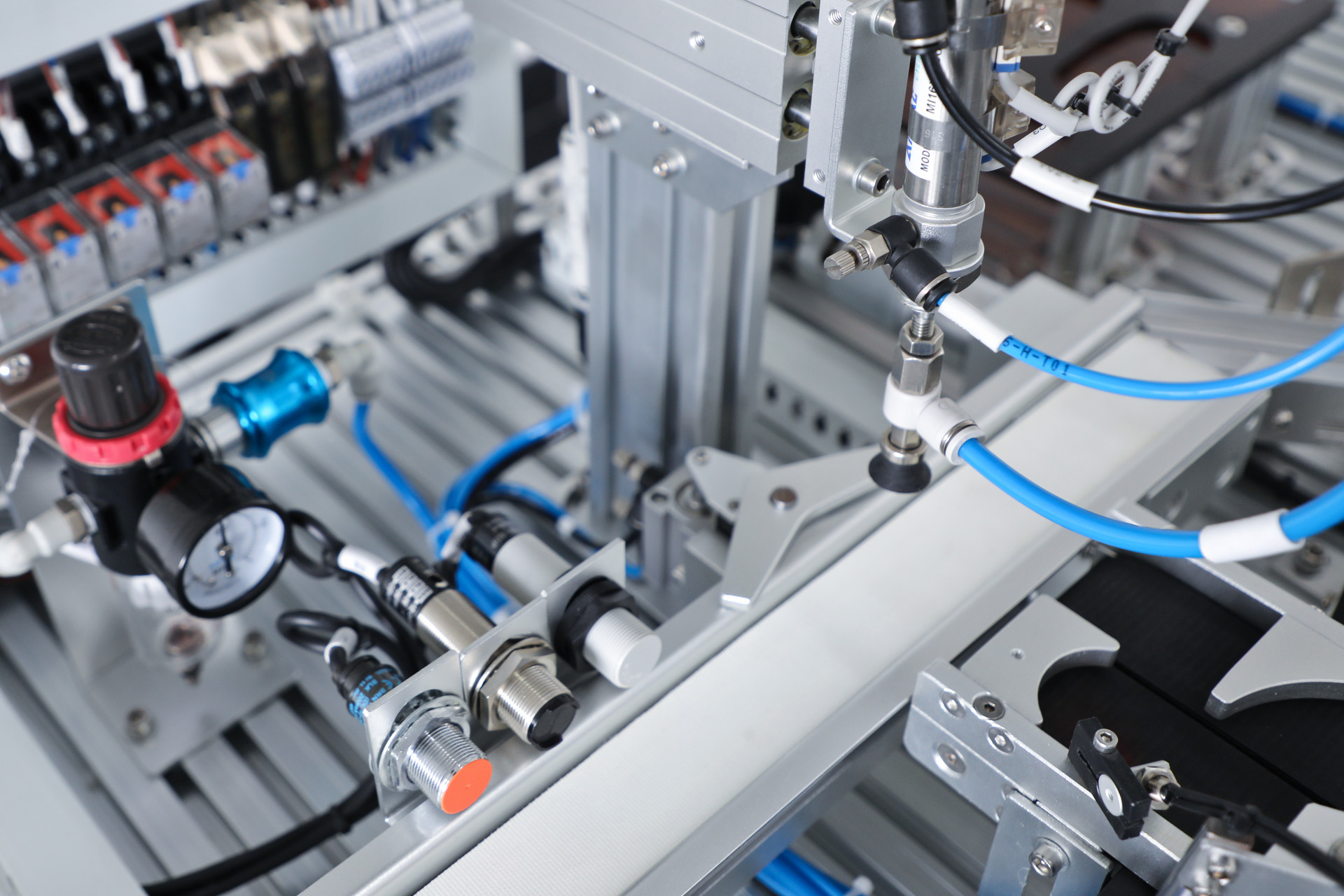

● Example 1: Power Cable Selection for Industrial Automation Equipment

Application Scenario:

An automated production line requires power supply for a 5.5kW three-phase induction motor. Supply voltage: 380V AC, cable length: 25m, ambient temperature: 40°C, installed in cable trays.

Selection Procedure:

- Current Calculation:

- Three-phase current formula: I = P/(√3×U×cosφ)

- With cosφ=0.85, calculated I≈9.83A

Preliminary Cross-section Selection:

- Refer to IEC 60287 for PVC-insulated copper cables at 40°C:

- 1.5mm²: 18A (direct burial) / 16A (bridge)

- 2.5mm²:24A/21A

- 1.5mm² is initially selected (16A>9.83A)

Voltage Drop Verification:

- Allowable voltage drop: 3% (11.4V)

- Three-phase voltage drop formula:ΔU=√3×I×L×(Rcosφ+Xsinφ)

- 1.5mm² parameters:R=12.1Ω/km,X≈0.08Ω/km

- Calculated ΔU≈4.8V (4.2%>3%, fails)

- Switch to 2.5mm² (R=7.41Ω/km), ΔU≈2.95V, (2.6%<3%, passes)

Final Selection:

● Cable specification: 3×2.5mm²+1.5mm² (PE conductor)

● Insulation rating: 0.6/1kV PVC

● UL Listed (US Safety Certification)

● Example 2: HV Harness Selection for New Energy Vehicles

Application Scenario:

Connection between EV battery pack and motor controller. Operating voltage: 650V DC, continuous current: 150A, harness length: 3.5m, temperature range: -40℃~125℃.

Selection Procedure:

- Current Carrying Capacity:

- ISO 6722 requires ≥35mm² for 150A

- High-temperature derating (0.8 factor)→187.5A required

- Select 50mm² (200A@125℃)

Voltage Rating Verification:

- Select 1000V-rated cable

- Insulation material: XLPE

- Insulation thickness: ≥1.4mm (LV 216 compliant)

Special Requirements:

- EMI shielding: Dual-layer foil+copper braid (>90dB)

- Bending performance: Min. bend radius=8×OD

Final Selection:

● Conductor: 50mm² tinned copper strand

● Jacket: Oil-resistant orange TPE

● Certification: E-MARK

Key Takeaways :

● Complete “Calculate→Select→Verify” process

● Mandatory derating for high-temperature environments

● Pay special attention to polarity marking in DC systems

● Special applications (PV/automotive) require industry-specific standards

● Different voltage drop formulas for 3-phase vs. DC systems

6. Common Misconceptions

In the process of electrical harness selection, engineers often fall into certain misconceptions due to lack of experience or inadequate consideration, leading to degraded equipment performance, safety hazards, or even system failures.

① Selecting Wire Based Only on Current While Ignoring Voltage Drop

● Issue: Focusing solely on whether the wire’s current-carrying capacity meets the equipment’s current requirements, while neglecting to calculate voltage drop in long-distance wiring.

ⅰ. Consequences:

● Insufficient power supply to remote equipment (e.g., motor starting difficulties, sensor signal abnormalities).

● In high-current scenarios, excessive voltage drop may cause false triggering of protection circuits.

ⅱ. Recommendations:

● For low-voltage systems (e.g., 12V/24V DC), voltage drop should be limited to ≤3%; for precision equipment (e.g., PLCs), ≤1% is recommended.

● For long-distance wiring, prioritize increasing wire gauge rather than relying solely on voltage boost compensation.

② Neglecting Insulation Ratings in High-Voltage Applications

● Issue: Misusing low-voltage cables (e.g., standard PVC insulation) in high-voltage systems (e.g., 400V EV battery packs).

ⅰ. Consequences:

● Insulation breakdown causing short circuits or even arc flashes (higher risks in HV systems).

ⅱ. Recommendations:

● Select insulation materials based on operating voltage (e.g., XLPE or silicone rubber for 600V systems).

● HV harnesses must comply with industry standards (e.g., ISO 6722, UL 2202).

③ Ignoring Ambient Temperature Effects on Current Rating

● Issue: Misusing low-voltage cables (e.g., standard PVC insulation) in high-voltage systems (e.g., 400V EV battery packs).

ⅰ. Consequences:

● Cable overheating accelerates aging, with carbonized insulation leading to leakage currents or fires.

ⅱ. Recommendations:

● Derate current-carrying capacity by 20-30% in high-temperature environments (>70°C).

● Use high-temperature-resistant cables (e.g., silicone rubber cables rated for 180°C).

④ Oversizing Conductors Causing Cost Inefficiency

● Issue: Excessively pursuing safety margins by selecting conductor sizes far exceeding actual requirements.

ⅰ. Consequences:

● Increased material costs (e.g., exponentially higher prices for large-cross-section copper cables).

● Increased installation difficulty (e.g., insufficient bend radius, connector mating issues).

ⅱ. Recommendations:

● Select minimum compliant conductor size through precise calculations (current + voltage drop).

● Allow slight margins for fixed installations; prioritize flexibility for moving harnesses (e.g., robotic arms).

⑤ Neglecting Mechanical Stress in Dynamic Environments

● Issue: Using standard rigid cables in vibrating/flexing applications (e.g., vehicles, robots).

ⅰ. Consequences:

● Conductor breakage/shield damage causing intermittent faults (difficult to diagnose).

ⅱ. Recommendations:

● Use high-flex cables for dynamic routing (e.g., drag chain cables with >1 million bend cycles).

● Add stress-relief features (e.g., cable clamps, spiral sleeves).

⑥ Confusing AC and DC Cable Selection

● Issue: Misapplying DC cables (e.g., PV DC side) in AC systems (e.g., inverter output).

ⅰ. Consequences:

● AC systems require larger conductors due to skin effect – direct substitution may cause overheating.

ⅱ. Recommendations:

● Prioritize multi-strand conductors for AC circuits (especially high-frequency).

● Ensure polarity marking in DC systems (e.g., color-coded +/- for PV cables).

7. Conclusion

● Issue: Misapplying DC cables (e.g., PV DC side) in AC systems (e.g., inverter output).

Selection of appropriate wiring harness specifications is a key link in the design of electrical systems, which directly affects the reliability, safety and operational efficiency of the equipment. Through the systematic analysis in this paper, we understand that harness selection requires comprehensive consideration of multiple factors such as current carrying capacity, voltage level, environmental factors and industry standards. From the accurate calculation of current-carrying capacity and voltage drop, to the reasonable selection of insulation materials and wire diameter specifications, and then optimized for special application scenarios, each step requires rigorous technical assessment and practical verification.

In actual engineering applications, engineers are advised to strictly follow the selection principle of “Calculation – Verification – Adaptation“: firstly, theoretical calculations are made based on electrical parameters, then performance indicators are verified through practical tests, and finally the best adaptation is made according to specific application environments. At the same time, special attention should be paid to avoid common selection errors, such as ignoring the voltage drop, wrong choice of insulation level, ignoring the impact of ambient temperature.

With the development of electrical equipment to high-voltage, high-current, high-density direction, the technical requirements of wiring harness selection will continue to improve. It is recommended that the design team continue to pay attention to the update of international standards (e.g. IEC, ISO, UL, etc.), and combine with actual test data to continuously optimize the selection scheme. Only the organic combination of theoretical calculations, standard specifications and engineering experience can ensure the long-term stable operation of the electrical system and provide safe and reliable power protection for the equipment.

Leave a Comment