Types and Applications of Wire Harness Assemblies in Different Fields

What is a Wiring Harness?

A wiring harness is a component that bundles multiple wires, cables, or optical fibers together according to specific rules, equipped with connectors, protective sleeves, and other accessories, used to transmi.

It is widely used in automotive, household appliances, industrial equipment, medical instruments, aerospace, and other fields, serving to connect, protect, and secure circuits, ensuring stable and reliable operation of electrical systems.

Selecting the correct wiring harness depends on your application scenario (e.g., automotive, industrial equipment), electrical performance (voltage, current, signal type), environmental requirements (high-temperature resistance, corrosion resistance, vibration resistance), harness specifications (wire gauge, length, connector type), safety standards (compliance with certifications like ISO, UL), and cost-effectiveness.

Ensure the wiring harness meets the electrical and mechanical requirements of the equipment while offering reliability and durability.

Classification of Wiring Harnesses

Classified by function into:

- Types and Applications of Wire Harness Assemblies in Different Fields

- What is a Wiring Harness?

- Classification of Wiring Harnesses

- ◆ Classification and Application of Automotive Wiring Harnesses

- ◆ Household Appliance Wiring Harnesses

- ◆ Industrial Equipment Wiring Harnesses

- ◆ Medical Equipment Wiring Harnesses

- ◆ Aerospace Wiring Harnesses

- ◆ Communication Equipment Wiring Harnesses

- ◆ Consumer Electronics Wiring Harnesses

- ◆ Marine Wiring Harnesses

- ◆ New Energy Wiring Harnesses

- ▼ How to Find the Right Wiring Harness for You? ▼

- ▼ If you have customized wiring harness needs, please feel free to contact us for exclusive solutions! ▼

◆ Classification and Application of Automotive Wiring Harnesses

Automotive wiring harness is the core component of the automotive electrical system, composed of wires, connectors, protective materials and fixings, etc. It is like the neural network of the vehicle, responsible for transmitting electrical energy and signals to various electronic and electrical components to ensure the normal operation of the vehicle.

It is divided into various types according to the function and installation location, such as power harness, body harness, etc., and with the development of automotive electronics and intelligence, it is constantly evolving to the direction of high voltage, high speed, lightweight and intelligence.

▶ Power System Harnesses

▪ Engine harness: Connects ECU, sensors (e.g., oxygen sensors), and actuators (e.g., fuel injectors), located in the engine compartment.

▪ Transmission harness: Connects TCU, gear position sensors, etc., located around the transmission.

▪ Chassis harness: Connects ABS/ESP systems, wheel speed sensors, etc., located at the vehicle bottom.

▶ Body System Harnesses

▪ Dashboard harness: Connects instrument clusters, infotainment screens, and AC control panels.

▪ Door harness: Connects window regulators, door locks, and side mirrors.

▪ Seat harness: Connects seat adjustment motors, heating/ventilation systems.

▪ Lighting harness: Connects the vehicle’s lighting system.

▪ Safety harness: Connects airbags and collision sensors.

▶ Infotainment System Harnesses

▪ Connects audio systems, navigation devices, and vehicle communication modules.

▶ Other Critical Harnesses

▪ Power distribution harness: Connects the battery and electrical components.

▪ CAN bus: Enables data transmission between control units.

▶ Key Features: Requires high-temperature resistance, vibration resistance, and corrosion protection. Evolves toward high-voltage, high-speed, and lightweight designs with vehicle electrification.

◆ Household Appliance Wiring Harnesses

Used in refrigerators, washing machines, air conditioners and other household appliances, connecting control boards, sensors and motors, requiring good insulation and durability.

Household appliance wiring harnesses are components for internal electrical connections in home appliances, consisting of wires, connectors and protective materials, responsible for transmitting power and signals to ensure proper appliance operation.

They are widely used in refrigerators, washing machines, air conditioners and other equipment, featuring heat resistance, aging resistance and good insulation properties to meet the complex working environments and safety requirements of appliances.

▶ Power System Harnesses

○ Main power harness: Connects the power plug to the appliance’s internal circuit, providing power to the mainboard, motors and other components.

○ Internal power harness: Distributes power within the appliance, connecting the power board, control board and various electrical components.

▶ Control System Harnesses

▪ Control panel harness: Connects the control panel to the mainboard, transmitting user commands.

▪ Sensor harness: Connects temperature sensors, humidity sensors, water level sensors etc. to the mainboard, transmitting environmental parameter signals.

▪ Display harness: Connects the mainboard to displays and indicator lights, transmitting display information.

▶ Drive System Harnesses

▪ Motor drive harness: Connects the mainboard to motors, transmitting control signals and power to drive motor operation.

▪ Compressor drive harness: Connects the mainboard to compressors, transmitting control signals and power to drive compressor operation.

▪ Heater drive harness: Connects the mainboard to heaters, transmitting control signals and power to drive heater operation.

▶ Other Harnesses

▪ Lighting harness: Connects the mainboard to lighting fixtures to provide internal illumination.

▪ Door switch harness: Connects door switches to the mainboard to detect door status.

▪ Grounding harness: Provides reliable grounding for internal circuits to ensure safety.

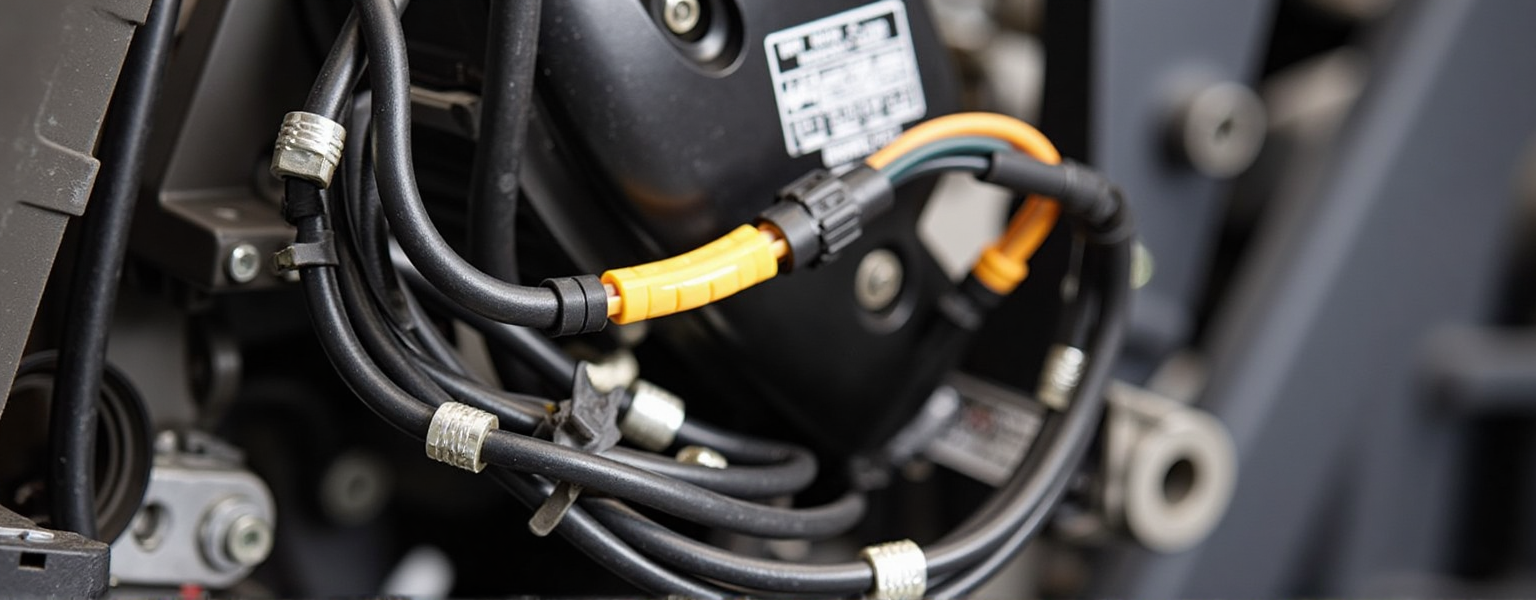

◆ Industrial Equipment Wiring Harnesses

Used in industrial machinery and automation equipment, connecting sensors, actuators and controllers, requiring high temperature resistance, oil resistance and interference immunity.

Industrial wiring harnesses are electrical connection components for industrial equipment and automation systems, composed of wires, connectors, protective sleeves, etc., responsible for transmitting power, signals and data to ensure stable equipment operation.

They are widely used in machinery, robots, production lines and other fields, featuring heat resistance, oil resistance, vibration resistance and electromagnetic interference immunity to adapt to complex industrial environments and high-intensity work requirements.

▶ Power System Harnesses

▪ Motor power harness: Connects motors and drives, transmitting high-voltage/high-current required for motor operation.

▪ Servo motor harness: Connects servo motors and controllers, transmitting control signals and feedback signals.

▪ Frequency converter harness: Connects frequency converters and motors, transmitting converted power and control signals.

▶ Control System Harnesses

▪ PLC control harness: Connects PLCs, I/O modules, sensors and actuators, transmitting control signals and status signals.

▪ Sensor signal harness: Connects various sensors (temperature, pressure, photoelectric, etc.) and controllers, transmitting sensor signals.

▪ Actuator control harness: Connects controllers and actuators (solenoid valves, cylinders, relays, etc.), transmitting control signals.

▶ Data Transmission Harnesses

▪ Industrial Ethernet harness: Connects industrial Ethernet devices, transmitting high-speed data.

▪ Fieldbus harness: Connects fieldbus devices, transmitting control signals and data.

▪ Encoder harness: Connects encoders and controllers, transmitting position and speed signals.

▶ Other Harnesses

▪ Power distribution harness: Distributes main power to various electrical equipment.

▪ Grounding harness: Provides reliable grounding for equipment safety.

▪ Lighting harness: Connects lighting equipment and power sources for work area illumination.

◆ Medical Equipment Wiring Harnesses

Used in medical instruments such as patient monitors and ultrasound equipment, requiring high reliability, sterilization resistance and biocompatibility.

Medical equipment wiring harnesses are electrical connection components for medical devices, consisting of wires, connectors, protective sleeves, etc., responsible for transmitting power, signals and data to ensure stable equipment operation.

They are widely used in patient monitors, ultrasound equipment, surgical instruments, etc., featuring high reliability, sterilization resistance, biocompatibility and electromagnetic interference immunity to meet the high standards and safety requirements of medical environments.

▶ Power System Harnesses

▪ Main power harness: Connects power sockets to the medical device’s internal circuit, providing power to mainboards, displays and other components.

▪ Internal power harness: Distributes power within medical equipment, connecting power boards, control boards and various electrical components.

▶ Signal Transmission Harnesses

▪ Sensor signal harness: Connects various sensors (ECG, SpO2, blood pressure, etc.) to mainboards, transmitting physiological signals.

▪ Image signal harness: Connects cameras, image sensors and image processing modules, transmitting image signals.

▪ Data communication harness: Connects medical equipment to computers and networks, transmitting medical data.

▶ Control System Harnesses

▪ Control panel harness: Connects control panels to mainboards, transmitting user commands.

▪ Motor control harness: Connects mainboards to motors, transmitting control signals and power to drive motor operation.

▪ Solenoid valve control harness: Connects mainboards to solenoid valves, transmitting control signals to regulate fluid/gas flow.

▶ Other Harnesses

▪ Lighting harness: Connects mainboards to lighting fixtures for internal or surgical area illumination.

▪ Grounding harness: Provides reliable grounding for medical equipment circuits to ensure safety.

▶ Key Features: Must comply with medical-grade standards, withstand repeated sterilization, and maintain signal integrity in sensitive medical environments.

◆ Aerospace Wiring Harnesses

Used in aircraft and spacecraft, connecting navigation, communication and control systems, requiring lightweight construction, extreme temperature resistance and radiation shielding capabilities.

Aerospace wiring harnesses are high-reliability electrical connection components for aircraft and spacecraft, composed of heat-resistant, corrosion-resistant wires, connectors and protective materials, responsible for transmitting power, signals and data to ensure normal operation of critical systems like flight control, navigation and communication.

They feature lightweight construction, extreme temperature resistance, radiation shielding and vibration resistance to meet the stringent environmental and safety requirements of the aerospace industry.

▶ Flight Control System Harnesses

▪ Flight control computer harness: Connects flight control computers, sensors (gyroscopes, accelerometers, etc.) and actuators (servos, ailerons, etc.), transmitting flight control signals.

▪ Autopilot harness: Connects autopilots, flight control computers and sensors, transmitting autopilot control signals.

▶ Navigation System Harnesses

▪ Inertial navigation system harness: Connects inertial navigation systems, flight control computers and displays, transmitting navigation data.

▪ Satellite navigation system harness: Connects satellite navigation receivers, flight control computers and displays, transmitting satellite navigation data.

▪ Radio navigation system harness: Connects radio navigation equipment (VOR, ILS, etc.), flight control computers and displays, transmitting radio navigation signals.

▶ Communication System Harnesses

▪ Radio communication harness: Connects radio communication equipment (VHF, HF, etc.), antennas and audio control panels, transmitting voice and data signals.

▪ Satellite communication harness: Connects satellite communication equipment, antennas and communication control panels, transmitting voice and data signals.

▪ Intercom harness: Connects communication equipment between crew members, transmitting voice signals.

▶ Power System Harnesses

▪ Engine control harness: Connects engine control units (ECUs), sensors (temperature, pressure, etc.) and actuators (fuel valves, igniters, etc.), transmitting engine control signals.

▪ Power distribution harness: Distributes power from generators and batteries to various electrical equipment.

▶ Other Harnesses

▪ Lighting system harness: Connects lighting equipment and power sources for internal and external aircraft illumination.

▪ Environmental control system harness: Connects environmental control equipment (AC, pressurization systems, etc.) and sensors, transmitting control signals and sensor data.

▪ Fire protection system harness: Connects smoke detectors, fire alarms and extinguishing systems, transmitting fire alarm and control signals.

▶ Key Features: Must meet strict aerospace standards, maintain signal integrity in extreme conditions, and ensure fail-safe operation in critical flight situations.

◆ Communication Equipment Wiring Harnesses

Used in communication base stations, routers and other equipment, connecting signal transmission and power modules, requiring high shielding and interference immunity.

Communication equipment wiring harnesses are electrical connection components for telecom base stations, routers and switches, composed of wires, connectors and protective materials, responsible for transmitting power, signals and data to ensure proper equipment operation.

They feature high shielding effectiveness, interference immunity and environmental resistance to meet the telecom industry’s stringent requirements for signal quality and equipment stability.

▶ Power System Harnesses

▪ Main power harness: Connects power sockets to the equipment’s internal circuit, providing power to mainboards and modules.

▪ Internal power harness: Distributes power within communication equipment, connecting power boards, control boards and various electrical components.

▶ Signal Transmission Harnesses

▪ RF signal harness: Connects antennas, RF modules and mainboards, transmitting RF signals.

▪ Baseband signal harness: Connects baseband modules, mainboards and interface boards, transmitting baseband signals.

▪ Clock signal harness: Connects clock modules to various functional modules, transmitting clock signals.

▶ Data Communication Harnesses

▪ Ethernet harness: Connects Ethernet interfaces to mainboards, transmitting Ethernet data.

▪ Fiber optic harness: Connects fiber optic interfaces to optical modules, transmitting optical signals.

▪ Serial port harness: Connects serial port interfaces to mainboards, transmitting serial data.

▶ Control Harnesses

▪ Control panel harness: Connects control panels to mainboards, transmitting user commands.

▪ Fan control harness: Connects mainboards to cooling fans, controlling fan speed.

▪ Indicator light harness: Connects mainboards to status indicators, displaying equipment status.

▶ Other Harnesses

▪ Grounding harness: Provides reliable grounding for internal circuits to ensure safety.

▶ Key Features: Must maintain signal integrity in high-frequency environments, provide EMI/RFI protection, and ensure stable power delivery for continuous operation.

◆ Consumer Electronics Wiring Harnesses

Used in smartphones, computers and other electronic products to connect internal components, requiring miniaturization, lightweight design and high reliability.

Consumer electronics wiring harnesses are electrical connection components for mobile phones, computers, tablets and other consumer electronic products, composed of wires, connectors and protective materials, responsible for transmitting power, signals and data to ensure proper device operation.

They feature miniaturization, lightweight design, high reliability and flex resistance to meet consumer electronics’ requirements for compact design and portability.

▶ Power System Harnesses

▪ Main power harness: Connects batteries to mainboards, providing power to devices.

▪ Charging harness: Connects charging interfaces to mainboards, transmitting charging current.

▶ Signal Transmission Harnesses

▪ Display signal harness: Connects mainboards to displays, transmitting display signals.

▪ Touchscreen signal harness: Connects mainboards to touchscreens, transmitting touch signals.

▪ Camera signal harness: Connects mainboards to cameras, transmitting image signals.

▪ Audio signal harness: Connects mainboards to speakers and microphones, transmitting audio signals.

▶ Data Communication Harnesses

▪ USB harness: Connects USB interfaces to mainboards, transmitting USB data.

▪ HDMI harness: Connects HDMI interfaces to mainboards, transmitting HD video and audio signals.

▪ Antenna harness: Connects antennas to mainboards, transmitting wireless signals.

▶ Control Harnesses

▪ Button harness: Connects buttons to mainboards, transmitting button signals.

▪ Sensor harness: Connects sensors (accelerometers, gyroscopes, etc.) to mainboards, transmitting sensor data.

▶ Other Harnesses

▪ Grounding harness: Provides reliable grounding for internal circuits to ensure safety.

▶ Key Features: Must achieve ultra-compact sizing for space-constrained designs while maintaining signal integrity and mechanical durability through repeated use.

◆ Marine Wiring Harnesses

Used in ship electrical systems to connect navigation, communication and power equipment, requiring corrosion resistance, moisture resistance and vibration resistance.

Marine wiring harnesses are electrical connection components for ship electrical systems, composed of corrosion-resistant and moisture-resistant wires, connectors and protective materials, responsible for transmitting power, signals and data to ensure normal operation of navigation, communication and power systems.

They feature high reliability, salt spray resistance, vibration resistance and electromagnetic interference immunity to adapt to complex marine environments and ship operation requirements.

▶ Power System Harnesses

▪ Main generator harness: Connects main generators to main switchboards, transmitting generated power.rounding for internal circuits to ensure safety.

▪ Emergency generator harness: Connects emergency generators to emergency switchboards, transmitting emergency power.

▪ Propulsion motor harness: Connects propulsion motors to frequency converters, transmitting propulsion power.

▶ Power Distribution Harnesses

▪ Main switchboard harness: Distributes main generator power to various electrical equipment.

▪ Emergency switchboard harness: Distributes emergency generator power to critical electrical equipment.

▪ Zone distribution board harness: Distributes power to electrical equipment in various zones.

▶ Lighting System Harnesses

▪ Deck lighting harness: Connects deck lighting fixtures to switchboards for deck illumination.

▪ Cabin lighting harness: Connects cabin lighting fixtures to switchboards for cabin illumination.

▪ Emergency lighting harness: Connects emergency lighting fixtures to emergency power sources.

▶ Navigation System Harnesses

▪ Radar harness: Connects radar antennas, radar displays and switchboards, transmitting radar signals.

▪ GPS harness: Connects GPS antennas, GPS receivers and switchboards, transmitting GPS signals.

▪ ECDIS harness: Connects ECDIS displays, sensors and switchboards, transmitting electronic chart data.

▶ Communication System Harnesses

▪ VHF radio harness: Connects VHF radio equipment, antennas and switchboards, transmitting VHF signals.

▪ MF/HF radio harness: Connects MF/HF radio equipment, antennas and switchboards, transmitting MF/HF signals.

▪ Satellite communication harness: Connects satellite communication equipment, antennas and switchboards.

▶ Automation System Harnesses

▪ Engine room automation harness: Connects automation equipment (PLCs, sensors, actuators) for engine room control.

▪ Ship management system harness: Connects management system equipment for integrated ship management.

▶ Other Harnesses

▪ Grounding harness: Provides reliable grounding for ship electrical systems to ensure safety.

▶ Key Features: Must maintain watertight integrity in harsh marine conditions while providing long-term reliability and electrical safety in saltwater environments.

◆ New Energy Wiring Harnesses

Used in electric vehicles, solar and wind power equipment to connect batteries, motors and control systems, requiring high temperature resistance, high voltage resistance and aging resistance.

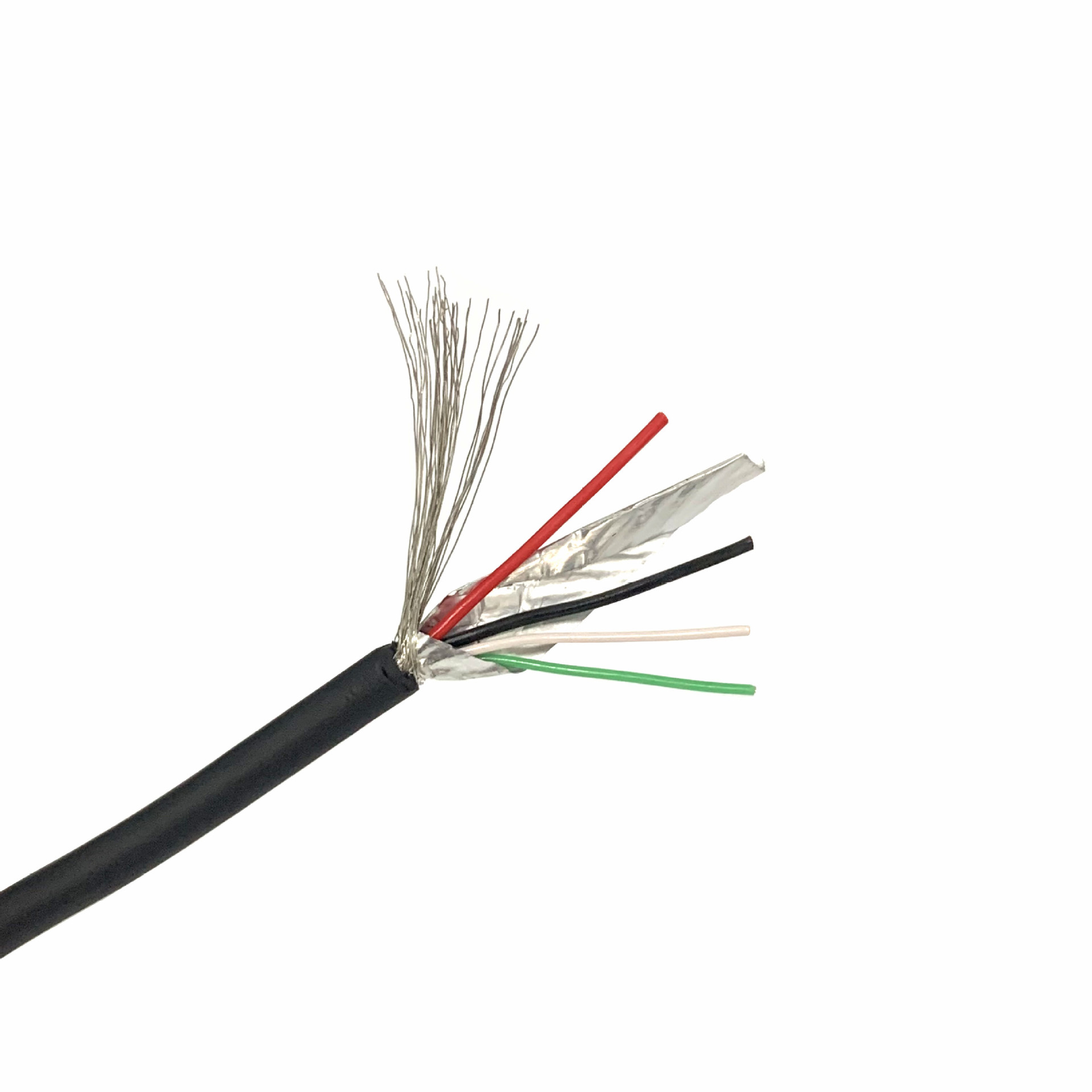

New energy wiring harnesses are core components of new energy vehicle electrical systems, primarily responsible for transmitting power and signals. They include high-voltage harnesses and low-voltage harnesses.

High-voltage harnesses connect critical high-voltage components like battery packs, motors, inverters and charging devices, transmitting high-voltage, high-current power. Low-voltage harnesses transmit low-voltage signals and small-power electricity, connecting sensors, controllers, lights and audio equipment.

These harnesses feature high current capacity, EMI resistance, heat resistance and corrosion resistance, with modular designs for easy installation and maintenance.

▶ Power Battery System Harnesses

▪ Battery module harness: Connects cells within battery modules, transmitting power.

▪ BMS harness: Connects BMS and battery modules, transmitting battery status data and control signals.

▪ High-voltage distribution box harness: Connects battery packs and motor controllers, distributing high-voltage power.

▶ Motor Drive System Harnesses

▪ Motor controller harness: Connects motor controllers and motors, transmitting control signals and power.

▪ Motor harness: Connects motors and motor controllers, transmitting power and control signals.

▶ Charging System Harnesses

▪ On-board charger harness: Connects on-board chargers and battery packs, transmitting charging current.

▪ Charging interface harness: Connects charging ports and on-board chargers, transmitting charging current.

▶ High-voltage Auxiliary System Harnesses

▪ DC/DC converter harness: Connects DC/DC converters and low-voltage batteries, converting high-voltage DC to low-voltage DC.

▪ PTC heater harness: Connects PTC heaters and battery packs for battery heating.nnects on-board chargers and battery packs, transmitting charging current.

▪ AC compressor harness: Connects AC compressors and motor controllers to drive compressors.

▶ Low-voltage System Harnesses

▪ Dashboard harness: Connects dashboard instruments, displays and control switches.

▪ Body harness: Connects body lights, horns, window motors, etc.

▶ Other Harnesses

▪ Grounding harness: Provides reliable grounding for new energy vehicle electrical systems.

▶ Key Features: Must ensure electrical safety under high-voltage conditions while maintaining long-term performance in extreme temperature environments.

▼ How to Find the Right Wiring Harness for You?▼

Choosing the right wiring harness is crucial for your project. As a professional wiring harness supplier, we provide comprehensive support to help you find the most suitable harness. Here are detailed steps and recommendations for selecting the right harness:

Leave a Comment