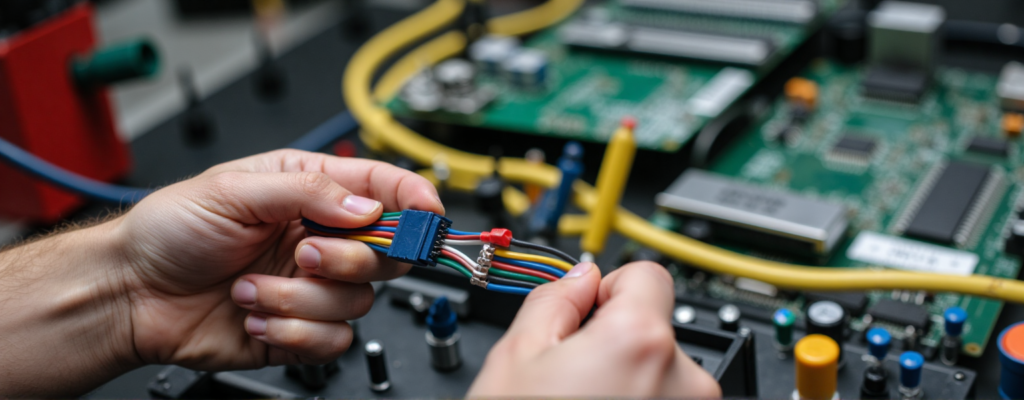

Three Essential Test Items for Harness Samples

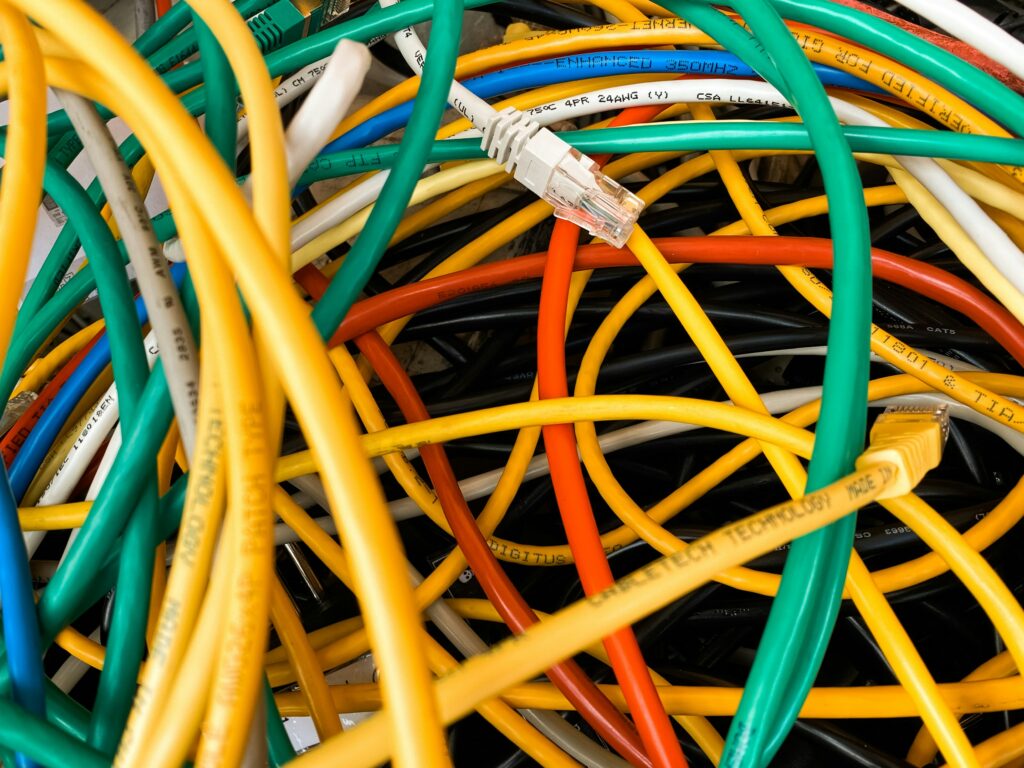

As the “blood vessels” of the electrical system, the quality of wiring harnesses directly affects the stability and safety of equipment operation. In order to ensure the reliability of wiring harnesses in complex working conditions, sample testing needs to focus on three core items: electrical performance, mechanical strength and environmental adaptability. The following is a step-by-step analysis of the required content and key standards from basic to severe conditions.

Table of contents

▶ Electrical Performance Testings

Electrical performance is the core function of a harness, directly affecting signal transmission quality, safety, and long-term reliability. Below are the details of electrical performance testing, covering key items, test methods, and industry standards.

1. Continuity Test

Purpose:

To verify the integrity of electrical connections in all harness wires, ensuring no open circuits, short circuits, misalignment, or poor contact.

Test Methods and Equipment:

- Equipment: Continuity tester (e.g., four-wire micro-resistance tester), multimeter, or automated continuity test bench.

- Methods:

- Connect the harness to the test probes or fixtures, and check the continuity between both ends of each wire.

- Record the resistance value of each wire and cross-check with design schematics to confirm path accuracy.

Key Parameters and Standards:

- Continuity Resistance: Typically ≤10mΩ (affected by wire gauge, length, and terminal crimping quality).

- Acceptance Criteria: If resistance is abnormal (e.g., open or short circuit), inspect terminal crimping, wire breakage, or insulation damage.

Notes:

- Clean terminals before testing to avoid increased contact resistance due to oxidation.

- Automated test equipment improves efficiency and is suitable for mass production.

2. Insulation Resistance Test

Purpose:

To evaluate the insulation performance of wire insulation layers, preventing leakage, short circuits, or safety risks due to insulation failure.

Test Methods and Equipment:

- Equipment: Insulation resistance tester (e.g., megohmmeter), high-voltage power supply.

- Methods:

- Apply 500V DC voltage between the wire and adjacent wires (or shielding layer) at room temperature (25°C) for 60 seconds.

- Measure and record the insulation resistance value.

Key Parameters and Standards:

- Standard Value: Insulation resistance should be ≥100MΩ per ISO 6722 or automotive industry requirements (special scenarios may require ≥500MΩ).

- Causes of Failure: Insulation scratches, material aging, or humid environments leading to resistance reduction.

Extended Applications:

For high-temperature or high-humidity tests, simulate extreme conditions (e.g., 85°C, 85% RH) in a climate chamber to validate insulation stability.

3. Hi-Pot Test (High Potential Test)

Purpose:

To verify the insulation withstand capability of the harness under high voltage, ensuring no breakdown or arcing under extreme conditions.

Test Methods and Equipment:

- Equipment: Hi-Pot tester (capable of AC/DC high-voltage output).

- Methods:

- AC Test: Apply AC 1500V (or per standards) at 50Hz for 1 minute.

- DC Test: Apply DC 3000V for 1 minute.

- Observe for breakdown, sparks, or sudden current surges.

Key Parameters and Standards:

- Acceptance Criteria: No breakdown or arcing (refer to UL 758, ISO 14572).

- Voltage Selection: Adjust based on harness operating voltage, e.g.:

- Low-voltage harness (12V): Test voltage is typically 500V AC.

- High-voltage harness (EV): Test voltage may exceed 2500V AC.

Risks and Precautions:

- Safety Measures: Isolate the test area to prevent accidental high-voltage contact.

- Failure Analysis: If breakdown occurs, inspect insulation thickness, material uniformity, or contamination.

4. Supplementary Tests (Optional but Critical)

Contact Resistance Test:

To verify the insulation withstand capability of the harness under high voltage, ensuring no breakdown or arcing under extreme conditions.

Voltage Drop Test:

Measure voltage drop across the wire under rated current to verify wire gauge meets current-carrying requirements (e.g., SAE J1128).

▷ Industry Standards and Equipment Requirements

- Key Standards: ISO 6722 (automotive cables), USCAR-2 (connectors), IEC 60512 (electrical component testing).

- Equipment Calibration: Regularly calibrate test instruments to ensure data accuracy (e.g., four-wire resistance testers eliminate lead errors).

▷ Test Reports and Corrective Actions

- Data Recording: Document raw test data (e.g., resistance values, withstand voltage results).

- Failure Analysis: Perform root cause analysis for non-conformities (e.g., poor terminal crimping, insulation defects).

- Corrective Actions: Optimize processes (e.g., adjust crimping pressure), replace materials, or redesign components.

※ Rigorous electrical performance testing ensures harness stability and safety in complex electrical environments, preventing system failures or accidents caused by electrical faults.

▶ Mechanical Performance Testing

Mechanical performance testing is a critical process to evaluate the durability and reliability of harnesses under physical stress, directly impacting their service life and damage resistance. Below are the detailed mechanical tests, covering key items, methods, and acceptance criteria.

1. Insertion/Extraction Force Test

Purpose:

To verify that the insertion/extraction forces of connectors meet design requirements, ensuring mating stability and service life.

Test Methods and Equipment:

- Secure the connector to the tester and simulate actual mating/unmating actions (e.g., 1-second dwell after insertion, 50mm/min extraction speed).

- Perform cyclic testing (e.g., 5,000 cycles) and record initial forces versus post-test changes.

Key Parameters and Standards:

- Force Range: Insertion force ≤50N, extraction force ≥5N and ≤30N (per USCAR-2).

- Acceptance Criteria: Force degradation rate <20%, with no terminal deformation or latch breakage.

Notes:

- Clean terminals before testing to avoid contamination affecting results.

- High-frequency testing (e.g., 100,000 cycles) applies to high-reliability scenarios (e.g., aerospace).

2. Flexing Test

Purpose:

To simulate bending conditions during installation or use, evaluating the fatigue resistance of wires and insulation.

Test Methods and Equipment:

- Equipment: Flexing tester (adjustable angle and frequency), wire clamps.

- Methods:

- Fix one end of the harness and repeatedly bend the other end at a set angle (e.g., 90°) and frequency (e.g., 30 cycles/minute).

- Post-test inspection for wire breaks, insulation cracks, or terminal loosening.

Key Parameters and Standards:

- Cycles: Typically ≥5,000 cycles (ISO 6722); automotive harnesses may require ≥10,000 cycles.

- Failure Criteria: Post-test resistance change ≤10%, insulation resistance ≥100MΩ.

Extended Applications:

Multi-directional bending tests: Simulate complex 3D flexing (e.g., robotic cables).

3. Tensile Strength Test

Purpose:

To evaluate the mechanical strength of wire-to-terminal crimps, preventing connection failure under external pulling forces.

Test Methods and Equipment:

- Equipment: Tensile testing machine (±1% accuracy), specialized clamps.

- Methods:

- Secure both ends of the wire and apply axial tension (e.g., 50N) for 60 seconds.

- Record the breaking force or maximum load before terminal detachment.

Key Parameters and Standards:

- Breaking Force: Wire breaking force must ≥ nominal tensile strength (e.g., 0.5mm² copper wire ≥80N).

- Terminal Retention: Crimped terminal-to-wire pull-off force must ≥80% of wire tensile strength (e.g., SAE J1128).

Failure Mode Analysis:

- Wire Breakage: Inferior wire quality or conductor damage during crimping.

- Terminal Detachment: Worn crimping dies or improper pressure settings.

4. Supplementary Tests (Optional but Critical)

Vibration Test:

Simulate operational vibrations (10-2000Hz frequency, 5-30g acceleration); inspect for terminal loosening or wire fatigue post-test.

Twist Test:

Apply specified torque (e.g., ±180°/meter) to validate torsional resistance (e.g., drag chain cables).

▷ Industry Standards and Equipment Requirements

- Key Standards: ISO 6722 (flexing), USCAR-21 (connector forces), SAE J1128 (tensile strength).

- Equipment Calibration: Regularly calibrate tensile testers and force testers to prevent data deviation.

▷ Test Reports and Corrective Actions

- Data Recording: Document raw data (e.g., force curves, cycle counts, breaking forces).

- Improvements: Optimize crimping (e.g., adjust pressure/die size) or upgrade to high-toughness insulation.

※ Mechanical performance testing ensures structural integrity of harnesses under frequent mating, bending, or external impacts, preventing system failures or hazards caused by mechanical defects.

▶ Environmental Reliability Testing

Environmental reliability testing validates a harness’s tolerance to extreme temperatures, humidity, vibration, and other harsh conditions, ensuring long-term stability and safety. Below are key test items and execution details based on real-world operating scenarios.

1. Thermal Cycling Test

Purpose:

To evaluate material stability and electrical reliability under drastic temperature changes, preventing fractures, poor contact, or insulation aging due to thermal expansion/contraction.

Test Methods and Equipment:

- Equipment: Temperature chamber (±2°C accuracy), continuity tester, insulation resistance tester.

- Methods:

- Place the harness in the chamber and cycle temperatures (e.g., -40°C to +125°C, 2 hours per cycle).

- After cycles (e.g., 100 cycles), immediately test continuity, insulation resistance, and inspect for oxidation, jacket cracking, etc.

Key Parameters and Standards:

- Temperature Range: Set per application, e.g., automotive harnesses require -40°C to +150°C (ISO 16750).

- Acceptance Criteria:

- Continuity resistance change rate ≤10%, insulation resistance ≥100MΩ.

- No cracks, terminal plating peeling, or seal failure.

Failure Scenarios:

- Insulation cracking due to low-temperature embrittlement or melting/adhesion at high temperatures.

- Terminal metal fatigue from thermal cycling, increasing contact resistance.

2. Damp Heat Test

Purpose:

To validate corrosion resistance and insulation performance in high-humidity/high-temperature environments, preventing short circuits or metal oxidation from moisture ingress.

Test Methods and Equipment:

- Equipment: Climate chamber (±3% RH accuracy).

- Methods:

- Expose the harness to 85°C, 85% RH for 500 hours (or 1000 hours per client requirements).

- Post-test, measure insulation resistance and inspect for terminal corrosion, insulation mold, or blistering.

Key Parameters and Standards:

- Insulation Resistance: ≥10MΩ (ISO 6722); high-voltage harnesses may require ≥100MΩ.

- Visual Criteria: No terminal rust, seal deformation, or water penetration.

Extended Testing:

Condensation Test: Simulate condensation erosion from diurnal temperature swings (e.g., ISO 20653 IPX9K).

3. Vibration Test

Purpose:

To simulate operational vibrations in vehicles or equipment, identifying risks of loose fixings, wire fatigue, or connector detachment.

Test Methods and Equipment:

- Equipment: Electrodynamic shaker (5-2000Hz frequency range), accelerometer.

- Methods:

- Set vibration parameters per ISO 16750-3 (e.g., 10-500Hz frequency, 30g acceleration, 8 hours per XYZ axis).

- Monitor continuity during testing; post-test, inspect wire abrasion, terminal loosening, or sheath displacement.

Key Parameters and Standards:

- Acceptance Criteria:

- No intermittent disconnections during testing; post-test resistance change ≤5%.

- No fixing point displacement or broken ties/clips.

Failure Prevention:

- Optimize routing to avoid metal contact friction.

- Use anti-slip clips or increase fixing point intervals.

4. Supplementary Tests (Optional but Critical)

Salt Spray Test:

Simulate coastal or de-icing salt environments; validate terminal corrosion resistance (e.g., 5% NaCl spray for 96 hours per ISO 9227).

UV Aging Test:

Evaluate outer jacket’s UV resistance (e.g., 1000-hour xenon lamp exposure per SAE J2527).

▷ Industry Standards and Equipment Requirements

- Key Standards: ISO 16750 (automotive environmental testing), IEC 60068 (general environmental tests), JASO D611 (Japanese automotive).

- Equipment Calibration: Regularly calibrate chambers and shakers to ensure parameter accuracy and test consistency.

▷ Test Reports and Corrective Actions

- Data Recording: Include temperature/humidity profiles, vibration spectra, and insulation resistance trends.

- Failure Analysis: For corrosion/aging, upgrade materials (e.g., gold-plated terminals, silicone insulation) or enhance sealing.

※ Environmental reliability testing comprehensively validates a harness’s adaptability to extreme climates, mechanical vibrations, and chemical corrosion, ensuring core safeguards for product longevity and safety.

○ Conclusion

Electrical, mechanical, and environmental reliability tests are the three core pillars of harness quality verification. They ensure reliability from functionality, durability, and environmental adaptability perspectives. Below is a table comparing the key aspects of these tests:

| Test Category | Key Test Items | Core Standards | Main Purpose |

|---|---|---|---|

| Electrical Performance | Continuity, Insulation Resistance, Dielectric Withstanding Voltage | ISO 6722, UL 758 | Ensure stable signal transmission and prevent leakage or short – circuit risks. |

| Mechanical Performance | Insertion/Extraction Force, Bending, Tensile Strength | USCAR – 2, ISO 6722 | Verify physical strength to avoid breaks or connection failures. |

| Environmental Reliability | Temperature Cycling, Humidity, Vibration | ISO 16750, IEC 60068 | Assess performance in extreme conditions and prevent aging or corrosion – related failures. |

Summary

- Synergy: These three tests collectively cover all lifecycle risks of a harness and are all essential.

- Data – Driven: Quantitative parameters (e.g., resistance, cycles, temperature/humidity ranges) allow precise quality grading.

- Industry Compliance: Adherence to ISO, IEC standards ensures global applicability and comparability of test results.

※ Companies should tailor test plans to specific application scenarios (e.g., automotive, industrial, or aerospace). Scientific and standardized processes are essential for ensuring long – term safe operation of harnesses.

No comments to show.

Leave a Comment