Lightweighting Solutions for Electric Vehicle Harnesses

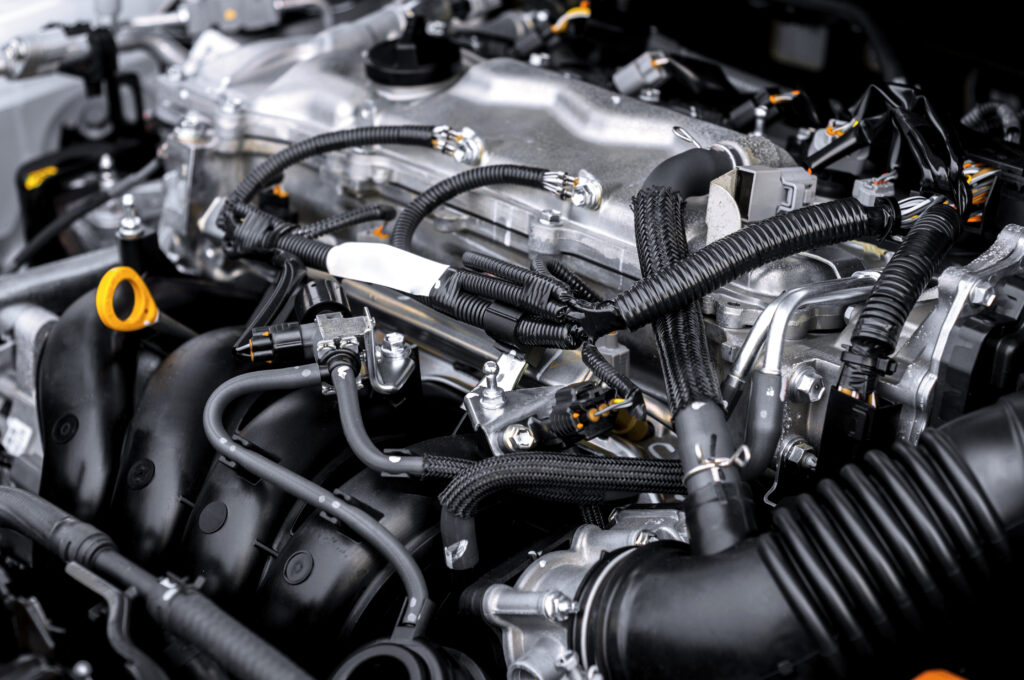

Lightweighting is crucial for extending the range, reducing costs, and increasing space utilization in electric vehicles. When it comes to harnesses, weight savings can significantly impact vehicle performance and efficiency.

Table of contents

1. Material Substitution and Optimization (Core Direction)

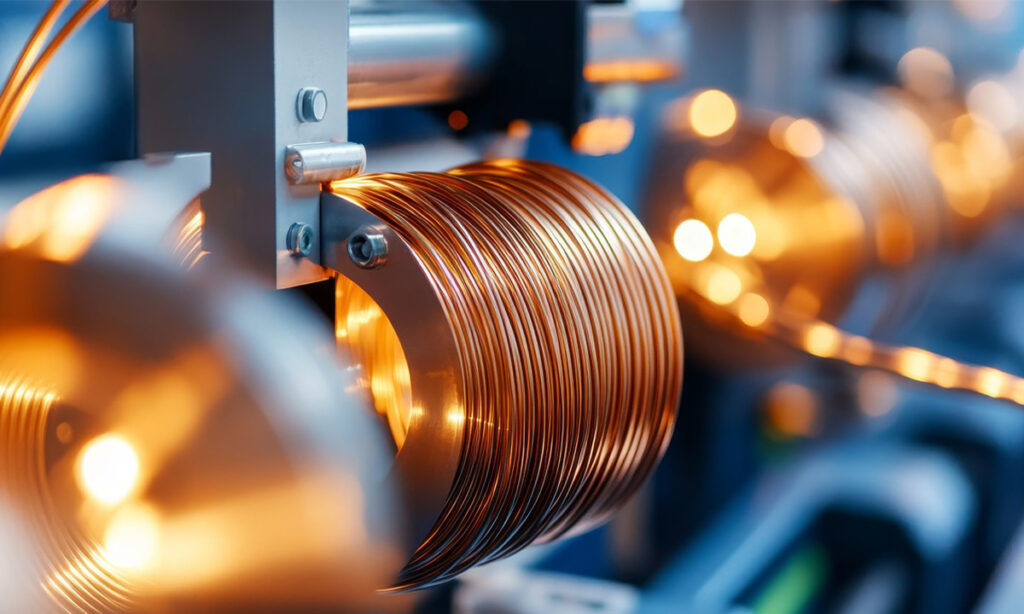

• Lightweight Conductor Materials:

Aluminum/Aluminum Alloy Conductors Replace Copper Conductors: Aluminum, with a density only 1/3 that of copper, is a primary means of lightweighting and is widely used in:

- Low-Voltage Harnesses: These include body harnesses and some signal harnesses, where aluminum’s weight reduction is particularly significant in long-distance applications.

- High-Voltage Harnesses (HV Cable): Given the higher demands for lightweighting in high-voltage systems (e.g., battery packs, connections between the battery and PDU/OBC, and from PDU to the motor), aluminum conductors have become mainstream. However, challenges such as lower conductivity (which may require larger cross-sectional areas), connection reliability (due to aluminum’s susceptibility to oxidation and creep), and specific welding/press-fitting processes must be addressed.

- Copper-Clad Aluminum Conductors: These combine aluminum’s lightweight nature with copper’s good conductivity and connectivity, making them a viable alternative to copper conductors in low-voltage harnesses, with costs falling between those of pure copper and aluminum.

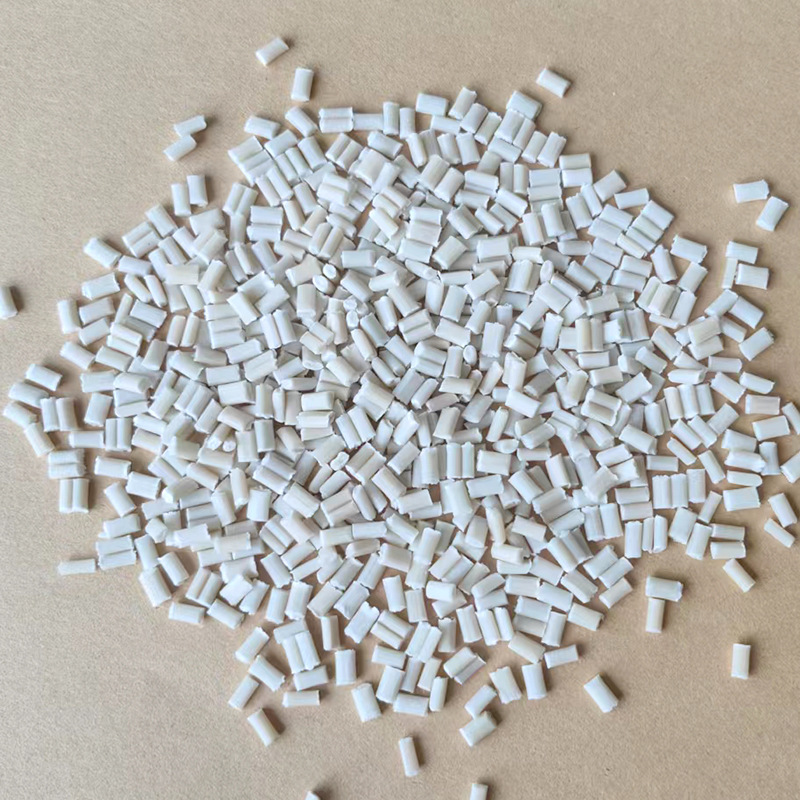

• Lightweight Insulation and Jacket Materials:

Thin-Wall Construction: Reduce the thickness of the insulation and jacket layers while maintaining electrical (voltage withstand, insulation) and mechanical (wear resistance, scratch resistance, flame retardancy) properties.

Low-Density, High-Performance Materials:

- Polypropylene: With a lower density than PVC and XLPE, polypropylene is commonly used for thin-wall insulation.

- Thermoplastic Olefins (TPO): These materials offer a good balance of flexibility, weather resistance, and flame retardancy, coupled with relatively low density.

- Low-Smoke, Halogen-Free Flame-Retardant Polyolefins: These materials meet higher environmental and safety standards, with ongoing efforts to develop lighter formulations.

- Foamed Insulation: Incorporating micro-pores into the insulation layer (e.g., foamed PE) effectively reduces density and improves dielectric constant and signal transmission performance, commonly applied in high-frequency cables such as coaxial cables.

• Optimized Shielding Materials:

- Aluminum Foil Shields Replace Braided Copper Shields: Aluminum foil, with its significantly lower density compared to braided copper layers, can substantially reduce weight, especially in scenarios where weight is a critical concern but shielding requirements are not extremely stringent.

- Composite Shield Structure Optimization: Optimize the braid density, number of layers, or adopt a combination of aluminum foil and sparse copper braid, to lighten the load while preserving shielding effectiveness.

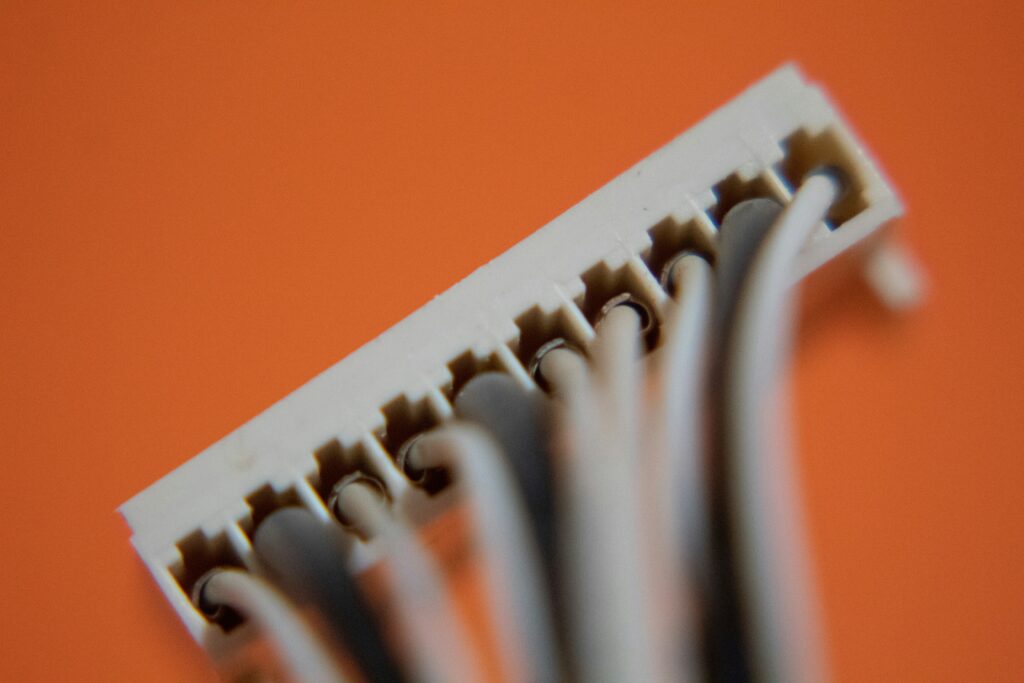

• Lightweight Connectors and Terminals:

- Miniaturized Design: Reduce the size of connectors and terminals while ensuring they meet current-carrying capacity requirements.

- Lightweight Material Selection: Utilize engineering plastics to replace some metal components (though strength and fire safety requirements must be maintained), and optimize terminal plating (e.g., using tin instead of some precious metals to meet performance criteria).

- Structural Optimization: Optimize the internal structure of connectors to eliminate redundant materials.

2. Structural Design and Topology Optimization

• Wire Size Optimization:

- Accurate Current Load Calculation: Precisely calculate the minimum cross-sectional area required for the conductor based on actual working conditions (rather than simply designing for the maximum current) to avoid over-design.

- Zonal Power Supply and Load Management: Use intelligent distribution boxes or regional controllers to power specific loads only when needed, reducing the length and cross-sectional area of conductors required to carry large currents continuously.

• Topology Architecture Innovation:

- Zonal Architecture: Transform the traditional ECU-centric “daisy chain” wiring to a zone-centered architecture. Each zone has a zone controller that communicates with the central computing unit via a limited number of high-speed main lines (such as Ethernet), while local power distribution and signal transmission are handled within the zone. This significantly reduces the length, weight, and complexity of the harness.

- Centralized High-Voltage Distribution: Optimize the layout and connection topology of high-voltage components to minimize the length and bending of high-voltage cables.

• Cable Type Integration:

- Coaxial Cables Replace Twisted Pairs: For high-speed data transmission (such as cameras, radar, and Ethernet), coaxial cables can transmit differential signals and power (PoC) on a single cable, reducing the number of cables and overall weight.

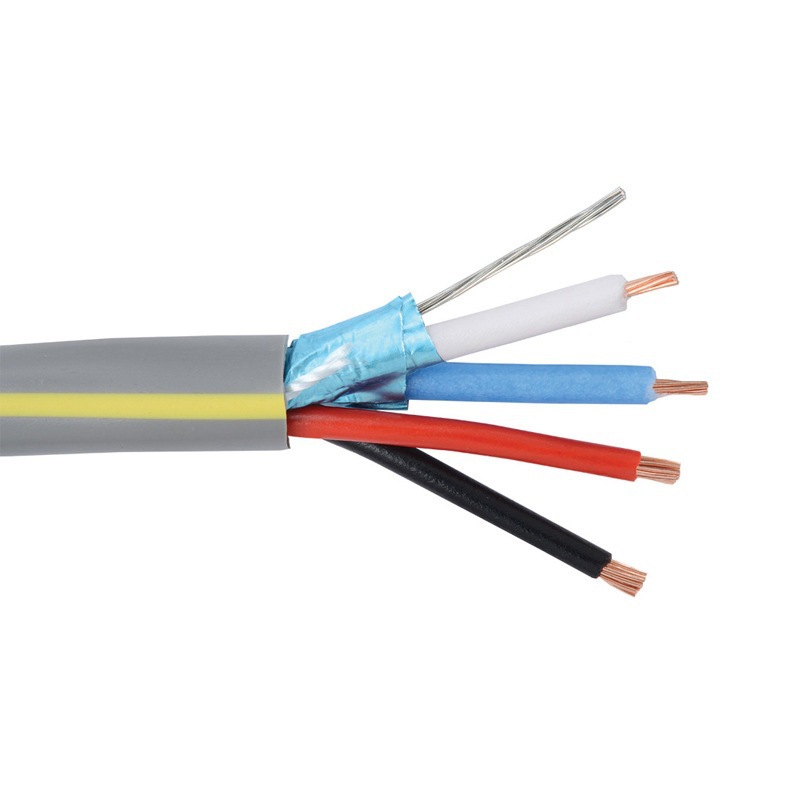

- Multi-core Cables: Combine multiple functionally similar or co-routed conductors into a single multi-core cable, sharing a common jacket layer, reducing total jacket material usage and assembly complexity.

• High-Voltage Platform Upgrade:

- System Voltage Increase: Transitioning from 400V to 800V or even higher voltage platforms allows for a significant decrease in current when transmitting the same power, which in turn permits the use of thinner conductors (smaller cross-sectional area), achieving substantial weight reduction. This is a major trend for high-voltage harness lightweighting.

3. Manufacturing Process Innovation

• Aluminum Conductor Connection Technologies:

- Ultrasonic Welding: A reliable mainstream technology for aluminum conductor connections, forming a metallurgical bond and avoiding oxidation and creep issues.

- Laser Welding: It offers high efficiency and minimal heat-affected zones, suitable for automated production.

- Special Press-Fitting Technologies: Develop press-fitting molds, process parameters, and terminal platings (such as tin or special alloys) specifically for aluminum conductors, to ensure stable and long-term reliable connections.

• Thin-Wall and Fine-Wire Processing Technologies:

- Develop more precise extrusion, cabling, cutting, and press-fitting equipment to handle the processing requirements of finer wires and thinner insulation layers, and ensure quality and yield.

• Automation and Precision:

- Enhance the degree of automation in harness production (such as automatic wire cutting, stripping, press-fitting, and assembly) to minimize human errors, control material usage and dimensions more accurately, and avoid waste.

4. Functional Integration and Simplification

• Wireless Communication Replaces Some Wired Connections:

- Where real-time and reliability requirements are met, use wireless technologies such as Bluetooth, Wi-Fi, and UWB to replace traditional wiring (e.g., some sensors, remote keys, internal connections in audio systems), directly reducing cable usage.

• Sensor/Actuator Integration:

- Combine multiple sensors or actuators into a single module, optimize internal wiring, and reduce external connections.

• Optimized Function Configuration:

- Evaluate during the vehicle design phase to remove redundant or unnecessary electrical functions, reducing the demand for harnesses from the outset.

Summary and Comparison

| Category | Measures | Weight Reduction | Technical Difficulty | Cost Impact | Main Application Scenarios/Advantages |

|---|---|---|---|---|---|

| Material Substitution and Optimization | Aluminum/copper-clad aluminum conductors, thin-wall insulation, low-density materials, aluminum foil shielding, miniaturized/lightweight connectors | High | Medium-High | Potential for cost reduction | Entire vehicle harness, particularly high-voltage harnesses and long-distance low-voltage harnesses |

| Structural and Topological Optimization | Zonal architecture, precise wire size calculation, coaxial/PoC, high-voltage platforms (800V+) | Very High | High | High initial investment | Revolutionary weight reduction, simplified design, improved manufacturability |

| Manufacturing Process Innovation | Aluminum conductor welding (ultrasonic/laser), dedicated press-fitting, thin-wall and fine-wire processing, high automation | Medium | High | High equipment investment | Ensuring the reliability and mass production feasibility of new materials and structures |

| Functional Integration and Simplification | Wireless replaces wired connections, sensor/actuator integration, optimized function configuration | Medium-Low | Medium | Potential for cost reduction | Auxiliary weight reduction, simplified system |

No comments to show.

Leave a Comment