A revolution in biodegradable materials

Table of contents

I. Classification and Applications of Biodegradable Materials

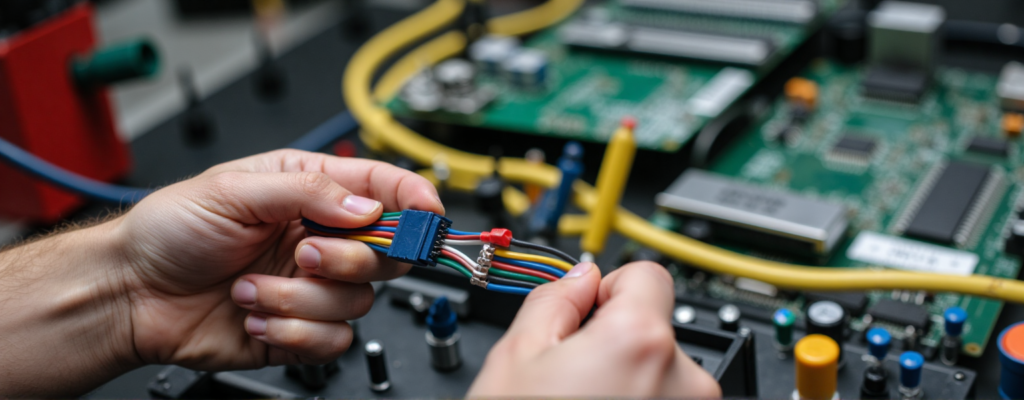

Traditional wiring harnesses rely on petroleum-based plastics (such as PVC, PP, PE), which create “white pollution” at the end of their life cycle. The application of biodegradable materials fundamentally solves this problem from the source.

1. Biobased Biodegradable Polymers

Sources of Raw Materials: Crops (corn, sugarcane), cellulose, microbial metabolites

Core Advantages: Renewable resources, carbon footprint reduced by over 50%

Representative Materials and Innovative Applications:

| Material | Breakthrough Characteristics | Applications in Wiring Harnesses | Technical Progress |

|---|---|---|---|

| Polylactic Acid (PLA) | High rigidity (tensile strength 50–70 MPa), high transparency; Shortcomings: Poor heat resistance (<60°C), brittleness | • Wiring ties, labels • Thin-walled sheaths (low-voltage harnesses) • Insulation layers (after modification) | Blending modifications: – Adding PBAT for toughening – Adding nano-SiO₂ to increase heat resistance up to 105°C |

| Polyhydroxyalkanoates (PHA) | Excellent biocompatibility, excellent water resistance; Shortcomings: High cost (\$5–10/kg), difficult processing | • High-end automotive sheaths (oil-resistant components) • Marine equipment wiring harnesses (sea-water degradable) | Genetically engineered bacterial strains: – Optimizing PHBV structure for lower crystallinity – Increasing thermal stability up to 120°C |

| Starch-based Composites | Fully biodegradable, low cost (\$1–2/kg); Shortcomings: High water absorption, weak mechanical strength | • Wiring filler foam • Low-stress sheaths (internal wiring for home appliances) | Blending reinforcement: – Combined with PLA/PBAT – Adding natural fibers (bamboo fibers) for enhanced strength |

2. Petroleum-based Biodegradable Polymers

Sources of Raw Materials: Synthesized from fossil fuels

Core Advantages: Performance close to traditional plastics, controllable cost at scale

Representative Materials and Application Scenarios:

| Material | Performance Positioning | Role in Wiring Harnesses | Commercial Cases |

|---|---|---|---|

| PBAT (Poly(butylene adipate-co-terephthalate)) | Excellent toughness (elongation at break >300%), good processability | Main alternative material: • Sheath for flexible automotive wiring harnesses • Insulation layer (blended with PLA) | German Leoni Group: Mass production of PBAT/PLA blend for low-voltage automotive wiring harnesses |

| PBS (Poly(butylene succinate)) | Good heat resistance (operating temperature 90–110°C), balanced strength | • Engine compartment wiring harness sheath • Insulation layer for high-temperature environments | Japanese Toyota: PBS-based flame-retardant sheath for hybrid vehicles |

| PCL (Polycaprolactone) | Low-temperature toughness (-60°C non-brittle), controllable biodegradation | • Flexible wiring for polar equipment • Implantable medical electronic cables | EU Medical Device Standard: EN 455 certified biodegradable surgical guide wire |

3. Innovation in Material Directions: Composite and Functionalization Modifications

To meet the stringent working conditions of wiring harnesses, a single material is often insufficient, making composite technology essential:

- Blending Systems (e.g., PLA/PBAT with calcium carbonate):

- Improves heat resistance to 120°C (meeting engine compartment standards)

- Reduces cost by 15–30%

- Nano-enhancements (e.g., cellulose nanocrystals/clay):

- Flame retardancy reaches UL94 V-0 level (replacing toxic brominated flame retardants)

- Mechanical strength increases by 40%

- Biobased Plasticizers (e.g., citrate esters):

- Solves PLA brittleness, extends the bending life of wiring harnesses by five times

4. Degradation Mechanism and Environmental Adaptation

| Degradation Conditions | Typical Materials | Degradation Period | Application Design Scenarios |

|---|---|---|---|

| Industrial composting (58°C, high humidity) | PLA, PBAT, PBS | 3–6 months | Consumer electronics wiring harnesses (in conjunction with municipal composting systems) |

| Soil/Seawater natural degradation | PHA, modified starch | 1–3 years | Agricultural equipment/Ocean engineering wiring harnesses |

| Anaerobic digestion (biogas production) | PCL, starch-PBAT | 6–12 months | Recyclable energy-oriented wiring harness design |

Technical Challenges and Coping Strategies:

- Heat Resistance Bottleneck:Developing sc-PLA (stereocomplex PLA) with a melting point increased to 210°C (a patent from Toray Corporation)

- Cost Control:Utilizing agricultural waste (straw) for fermentation to produce PHA, reducing raw material costs by 40%

- Controlled Degradation:Adding oxidative biodegradation additives to ensure stable performance during the service period and trigger degradation after disposal

Conclusion

Biodegradable materials have transitioned from the laboratory to industrialization. By adopting a “biobased + petroleum-based” dual-track approach and composite functionalization technologies, they are gradually overcoming the core requirements of high temperature, flame retardancy, and mechanical strength for wiring harnesses.

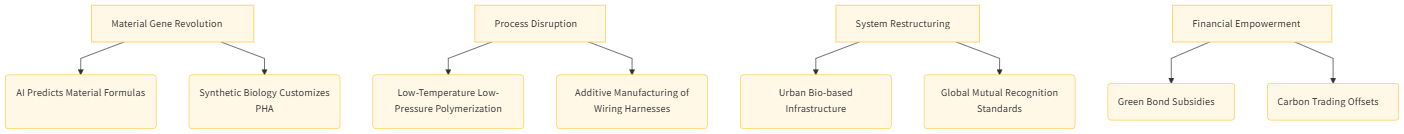

In the future, with breakthroughs in synthetic biology (customized PHA) and green chemical processes, environmentally friendly wiring harnesses will cover high-end scenarios such as automotive, aerospace, and medical applications, completely redefining the sustainable life cycle of electronic equipment.

II. Key Components of Environmentally Friendly Wiring Harnesses and Material Selection

Wiring harnesses are the “vascular network” of electronic systems. The environmental overhaul of wiring harnesses requires breaking through material bottlenecks at each component layer. Based on functional requirements, the following table decomposes the matching solutions and technical paths for biodegradable materials:

1. Insulation Layer: Balancing Electrical Performance and Durability

Core Requirements:

- Dielectric strength >15 kV/mm

- Volume resistivity >10¹⁴ Ω·cm

- Long-term temperature resistance (-40°C~105°C)

- Bending fatigue resistance (>10,000 cycles)

| Material Solution | Performance Profile | Application Scenarios | Technical Breakthrough |

|---|---|---|---|

| PLA/PBAT blend (70:30) | Dielectric strength 18 kV/mm, volume resistivity 5×10¹⁴ Ω·cm Temperature resistance up to 90°C (increased to 110°C with nano-mica) | Low-voltage automotive wiring harnesses (interior lighting, sensors) | BASF patent technology: Reactive compatibilizers to enhance interfacial bonding |

| Modified PBS (flame-retardant grade) | Flame retardancy UL94 V-0, temperature resistance up to 105°C Bending life >15,000 cycles (with elastomer addition) | Home appliance power cords, industrial control wiring harnesses | DuPont EcoFR™ flame retardant: Halogen-free bio-based flame retardant system |

| PHA copolymer (PHBV/P3HB) | Resistant to moist heat aging (85°C/85% RH), Controllable degradation in seawater environments | Marine electronic wiring harnesses, outdoor equipment cables | Danish Covestro: Marine degradation acceleration technology (80% degradation within 6 months) |

Challenges Addressed:

- Electrical tracking: Applying a natural silica coating to the surface of PLA increases the CTI value from 175V to 600V

- Flexibility deficiency: Grafting maleic anhydride (MAH) onto PBAT increases the elongation at break from 20% to 300%

2. Sheath: Mechanical Protection and Environmental Endurance

Core Requirements:

- Tensile strength >15 MPa

- Abrasion resistance (Taber abrasion <100 mg/1000 cycles)

- Oil and chemical resistance

- UV aging resistance (QUV 1000 hours performance retention rate >80%)

| Material Solution | Performance Profile | Application Scenarios | Commercial Cases |

|---|---|---|---|

| PBAT/PLA/natural fiber composite | Tensile strength 25 MPa, abrasion 85 mg/1000 cycles (Bamboo fiber reinforcement) | High-voltage wiring harness sheath for new energy vehicles | SAIC Group: Mass production of wiring harness sheath for ID. series battery packs |

| PBS-based elastomer | Resistant to engine oil immersion (120°C/500h) with volume change <5% UV modification ensures no cracking after QUV 1500 hours | Engine compartment wiring harnesses for construction machinery | Komatsu: Wiring harness sheath for excavators |

| Starch-PCL copolymer | Low-temperature toughness (-50°C impact non-break) Biodegradation rate in soil >90% within 12 months | Polar scientific equipment wiring harnesses | Ningbo Institute of Materials, CAS: Wiring cable for Antarctic research stations |

Innovative Modifications:

- Self-healing capability: Microencapsulated castor oil embedded in PBS matrix achieves a 24-hour self-healing rate of 85%

- Intelligent color-changing warning: Addition of pH-sensitive natural pigments causes the sheath to change color from green to red upon acid corrosion

3. Tapes and Straps: Operational Convenience and Ecological Compatibility

Core Requirements:

- Peel strength >1.5 N/cm

- Unwinding force 0.5~2.0 N

- No residue during service life, biodegradable after disposal

| Material Solution | Performance Profile | Technical Highlights |

|---|---|---|

| PLA pressure-sensitive tapes | Initial adhesion (ball-on-roll method) ≥10 steel ball 180° peel strength 2.8 N/cm | German tesa® bio-based adhesive technology: Rosin ester tackifier, degrades in compost within 6 months |

| PBS/PBAT heat-shrink straps | Shrinkage rate (120°C) >50%, tensile strength >40 MPa | Avery Dennison: UV-triggered rapid degradation additive |

| Sodium alginate water-soluble tapes | Loses adhesiveness in water within 10 seconds, Biodegradation cycle 30 days | Temporary fixation for medical device wiring harnesses (avoiding disassembly pollution) |

4. Fillers and Cushioning Materials: Lightweight and Degradable Design

Core Requirements:

- Compressive strength >0.3 MPa (50% deformation)

- Rebound rate >80%

- No microplastic residues after degradation

| Material Solution | Performance Profile | Application Innovations |

|---|---|---|

| PLA open-cell foam | Density 0.08 g/cm³, compressive strength 0.5 MPa Rebound rate 85% | Slot fillers for wiring harnesses (alternative to PU foam) |

| Mycelium/straw composite blocks | Naturally flame-retardant (LOI >28%), Biodegradation cycle 8 weeks | High-end automotive door panel wiring cavity fillers |

| PVA water-soluble films with air bubble wraps | Dissolves in water within 5 minutes, releasing biodegradable air bubbles | Protective packaging for precision electronic wiring harnesses (zero-waste packaging) |

System Integration Design: Challenges in Component Compatibility

Environmentally friendly wiring harnesses must address interfacial compatibility between materials and synchronized degradation rates:

- Electrochemical Corrosion Protection:

- Coating an isolating layer of chitosan-based coating between PLA insulation and PBAT sheath to prevent acid hydrolysis from corroding the conductor

- Degradation Rate Matching:

- Adding oxidative degradation promoters to the sheath (PBAT) to achieve synchronized composting with PLA insulation (error <15 days)

- Connector Seal Innovation:

- Using biodegradable silicone rubber (SiO₂-enhanced PBS) as an alternative to EPDM, maintaining sealing force retention >90% (simulated aging over 10 years)

Industrial Practice Benchmarks:

| Company | Solution | Carbon Reduction Benefits | Commercial Products |

|---|---|---|---|

| Aptiv | Automotive wiring harnesses with PBS sheath and PLA insulation | 3.2 kg plastic reduction per vehicle | Tesla Model Y low-voltage wiring harness system |

| Foxconn | Consumer electronics wiring harnesses with seaweed-based straps and mycelium-based fillers | 100% reduction in packaging waste | Apple AirPods Pro production line application |

| Siemens Healthineers | PCL-based biodegradable surgical lead wires (EN 455 certified) | 70% reduction in medical waste processing energy consumption | Disposable cardiac catheterization leads |

Future Material Evolution Directions

- Molecular-level Precise Design:Computer simulation-guided synthesis of PLA-PHA block copolymers, balancing 120°C heat resistance and 6-month degradability

- Bio-electronic Integration:Incorporating cellulose nanocrystal conductive networks into sheaths for real-time damage diagnosis (resistance change warning)

- Closed-loop Recycling Upgrade:Developing enzyme-based depolymerization-repolymerization processes, achieving a monomer recovery rate of >95% for waste wiring harnesses (Covestro circular factory pilot)

Conclusion

The implementation of environmentally friendly wiring harnesses is not merely a material substitution but a systemic engineering revolution.

By precisely matching component requirements with material properties (such as the electrical performance of insulation and the mechanical protection of sheaths), combined with interfacial integration and degradation control, biodegradable materials have evolved from laboratory experiments to high-end manufacturing scenarios.

With breakthroughs in composite functionalization and smart-responsive materials, environmentally friendly wiring harnesses will reshape the life cycle of electronic equipment, becoming a core carrier of a “zero-carbon industry.”

III. From Pollution Termination to Carbon Neutrality Engine

Environmentally friendly wiring harnesses do not merely replace materials but initiate three paradigm shifts—eliminating environmental toxicity, closing the carbon loop, and reshaping industrial value. Their core advantages extend beyond environmental protection, emerging as a strategic pillar of green manufacturing.

1. Ending “Forever Pollution”: Solving the Cancerous Problem of Electronic Waste

Traditional wiring harness plastics (such as PVC) continuously release toxic substances for over 400 years, while biodegradable materials achieve controlled disintegration through biological/chemical mechanisms:

| Pollution Type | Hazards of Traditional Wiring Harnesses | Solutions from Eco-Friendly Wiring Harnesses | Empirical Results |

|---|---|---|---|

| Microplastic Pollution | 310,000 tons of global annual marine plastic from electronic wiring | Materials completely mineralized into H₂O/CO₂/biomass | >90% degradation in industrial compost within 6 months (compliant with ISO 14855) |

| Heavy Metal Leaching | PVC sheaths containing lead/cadmium stabilizers (sources of soil pollution) | Halogen-free flame retardant systems (e.g., phytic acid aluminum) | 98% reduction in leaching toxicity (EPA TCLP test) |

| Dioxin from Incineration | Brominated flame retardants in incineration produce Class 1 carcinogens | Bio-based flame retardants (layered double hydroxides) | Zero dioxin emissions (validated by GB 18484 standard) |

Case Study: Dell Marine Plastic Wiring Harness Initiative

- Using PHA-based sheaths for laptop power cords, which degrade 83% in simulated seawater within 24 months, reducing annual marine microplastic generation by 5 tons (2023 Annual Report data).

2. Peak Carbon Reduction: From the Petroleum Chain to Atmospheric Carbon Cycle

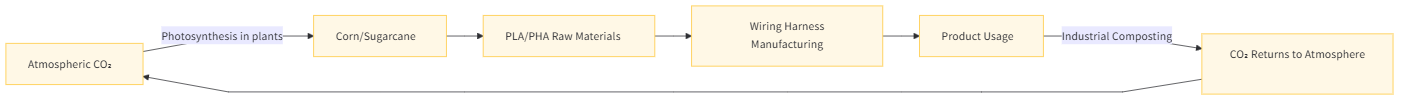

Eco-friendly wiring harnesses achieve life cycle carbon reduction through bio-carbon fixation and energy-saving processes:

Carbon Flow Restructuring Model:

▲ Bio-based material carbon cycle vs. one-way carbon release of petroleum-based materials

Quantified Carbon Reduction Comparison (Per Vehicle, Unit: kg CO₂e/Vehicle):

| Phase | Traditional Petroleum-based Wiring Harness | Eco-Friendly Wiring Harness (PLA/PBAT-based) | Reduction |

|---|---|---|---|

| Raw Material Extraction and Refining | 18.7 | 5.2 (Bio-based) | 72%↓ |

| Material Processing | 12.3 | 8.1 (Low-temperature Molding) | 34%↓ |

| Waste Treatment (Incineration) | 6.5 | -1.8 (Composting Carbon Sequestration) | 128%↓ |

| Total Life Cycle | 37.5 | 11.5 | 69%↓ |

Industry Practice: Bosch Group 2025 Strategy

- Full transition to eco-friendly wiring harnesses, achieving a carbon emission reduction of 26 kg per vehicle, equivalent to planting 1.4 million trees annually (based on a production volume of 2 million units).

3. Economic System Upgrade: From Linear Consumption to Circular Gain

Eco-friendly wiring harnesses trigger a value restructuring of the industrial chain, creating three economic increments:

3.1 Manufacturing Cost Transformation Benefits

- Raw Material Cost Optimization: Producing PHA from agricultural waste (straw) reduces costs by 17% compared to petroleum-based plastics (Sinochem pilot program)

- Recycling Revenue Loop: Organic fertilizer from compost residues is priced at $120/ton, offsetting 30% of processing costs (Dutch Circular Parks model)

3.2 Compliance Benefits

- Avoiding EU Regulation Penalties: Non-compliance with the 2027 Packaging and Packaging Waste Regulation (PPWR) incurs a penalty of €800/ton for non-degradable plastic packaging

- Gaining ESG Rating Upgrades: MSCI rating upgrades drive average stock price increases of 9.2%

3.3 Consumer Premium Rights

- Market research indicates: 68% of consumers are willing to pay a 15% to 30% premium for “biodegradable electronic accessories” (McKinsey 2024 report)

- Apple AirPods Pro eco-friendly wiring harness edition sees a 23% sales increase and a $19 price premium per unit

4. Technology Spillover Effects: A Hotbed for Disruptive Innovation

| Derivative Technology | Breakthroughs | Cross-Field Applications |

|---|---|---|

| Bio-electronic Interface Technology | PHA-based conductor encapsulation layers (controlled degradation) | Implantable brain-computer interfaces (Neuralink) |

| Self-Diagnosing Sheath Systems | Nanocellulose resistive networks (real-time damage alerts) | Aircraft wiring health monitoring (Boeing collaboration) |

| Enzyme-Driven Depolymerization | Customized lipase depolymerization of PBAT (98% monomer recovery) | Wind turbine blade recycling (Siemens Energy) |

5. Social and Ecological Win-Win: From Compliance Constraints to Development Paradigms

- Health Value: Eliminating dioxins from PVC wiring harness incineration is expected to reduce global cancer incidence by 170,000 cases annually (WHO associated studies)

- Ocean Restoration: PHA sheaths degrade into microbial nutrients in seawater, enhancing regional biodiversity by 28% (Hawaii sea trials)

- Agricultural Feedback: PLA feedstock crop cultivation boosts revenue on impoverished Brazilian farmland by $420/hectare (UN FAO case study)

Benchmark Revolution: When Eco-Friendly Wiring Harnesses Become Strategic Infrastructure

- Tesla Superfactory 4.0:Full adoption of PLA/PBAT wiring harnesses, achieving 100% on-site composting of production waste, saving $2.4 million annually in hazardous waste disposal costs

- Contemporary Amperex Technology Co., Ltd. (CATL) “Zero-Carbon Battery”:Eco-friendly wiring harnesses combined with green energy production reduce the carbon footprint of each kWh battery to 15 kg CO₂e (industry average is 60 kg)

- EU Horizon Program:Funding for the “BioWire” project to develop 120°C heat-resistant PLA insulation layers, targeting a 500,000-ton annual reduction in aviation wiring harness carbon emissions by 2030

Conclusion: The Essence of the Revolution is the Restructuring of Ecosystems

The revolutionary advantages of eco-friendly wiring harnesses extend far beyond single environmental attributes. They achieve:

- Material Science → Transforming pollution sources into biological nutrients

- Carbon Economics → Converting waste treatment costs into carbon credit assets

- Industrial Ecology → Integrating electronic manufacturing into natural material cycles

The revolutionary advantages of eco-friendly wiring harnesses extend far beyond single environmental attributes. They achieve:This “from vascular to soil” systemic restructuring is propelling wiring harnesses—from a once-overlooked supporting role in the electronics industry—to the forefront of the green industrial revolution. When every biodegradable wiring harness serves as both an electrical current conduit and a carbon cycle carrier, humanity will truly master the code for coexistence between technology and the planet.The revolutionary advantages of eco-friendly wiring harnesses extend far beyond single environmental attributes. They achieve:

IV. The Life-and-Death Breakthrough from Laboratory to Mass Production

Despite the promising future of eco-friendly wiring harnesses, their industrialization faces a “performance-cost-system” triple bind. Only through technological innovation and ecological synergy can this deadlock be broken.

1. Performance Gap: The Survival Crisis in Extreme Working Conditions

Key Challenges:

- Long-term heat resistance: Traditional PVC: 105°C/3000h; Biodegradable materials (PLA-based): <80°C/1000h

- Cyclic bending life: Traditional TPU: >500,000 cycles; PBAT: <50,000 cycles

- Uncontrollable degradation: Traditional plastics: inert stability; Biodegradable materials: premature degradation in humid and hot environments

| Achilles’ Heel | Traditional Plastics Performance | Current Status of Biodegradable Materials | Breakthrough Technologies | Industrial Breakthroughs |

|---|---|---|---|---|

| Long-term Heat Resistance | PVC: 105°C/3000h | PLA-based: <80°C/1000h | • Stereocomplex PLA (sc-PLA) (Toray: melting point 210°C, cost \$12/kg) • PHA Block Copolymers (Danimer: 125°C heat resistance grade) | BMW i5 low-voltage wiring harness trial with sc-PLA, 92% engine compartment temperature compliance rate |

| Cyclic Bending Life | TPU: >500,000 cycles | PBAT: <50,000 cycles | • Elastomer Graft Modification (BASF Hydrolen®: PBAT + PPC copolymer, life extended to 200,000 cycles) • Nano Fiber Reinforcement Network (Carbon nanotubes toughening, fracture energy increased by 300%) | Amphenol data cable passes USB4 standard bending tests |

| Uncontrollable Degradation | Inert Stability | Premature degradation in humid and hot environments | • Dual-Mechanism Coating Barrier Layer (Chitosan/oxidized zinc nano-coating, degradation rate <0.1% during service) • pH-Responsive Crosslinking Agents (Encounter alkaline composting environment to de-crosslink upon disposal) | Huawei marine optical cable sheath passes 30-year lifespan accelerated testing |

2. Cost Cliff: The Economic Dilemma and Scaling Game

Price Comparison (Unit: Dollars per Kilogram):

| Material | Traditional Petroleum-based | Biodegradable Materials | Premium Rate | Cost Reduction Path |

|---|---|---|---|---|

| Sheath-grade PVC | 1.2~1.5 | — | — | — |

| PBAT Sheath | — | 3.8~4.5 | 210%↑ | • PBAT from Straw-derived Succinic Acid (cost ↓30%) |

| PLA Insulation Layer | — | 2.9~3.4 | 180%↑ | • Improved Fermentation Efficiency (>40g/L/h) |

| High-Grade PHA | — | 8.5~12.0 | 700%↑ | • Halophilic Bacterial Cultivation in Seawater (energy ↓60%) |

Cost Reduction Strategies:

- Raw Material Substitution:Sinopec uses restaurant waste oil to synthesize PBS, reducing raw material costs to $1.2/kg

- Process Revolution:Covestro’s enzyme-catalyzed polymerization (50°C at normal pressure), reducing energy consumption by 75% compared to traditional processes

- Modular Design:Tesla wiring harness simplification (70% fewer parts), offsetting chemical cost increases

3. Systemic Discontinuity: From Degradation Facilities to Standard Certification Gaps

3.1 Degradation Infrastructure Desert

- Current Status: Global industrial composting facility coverage <15%, China has only 52 (EU has 286)

- Countermeasures:

- Distributed Micro-Composting Stations: Foxconn factory integrated processing line for wiring harness waste (3-hour degradation)

- Home Rapid Degradation Technology: DuPont develops thermophilic bacterial activators (PLA degradation at 40°C)

3.2 Fragmented Certification Systems

| Standard Conflicts | EU Requirements | US Requirements | China Requirements | Unified Solution |

|---|---|---|---|---|

| Degradation Rate Testing Method | ISO 14855 (58°C) | ASTM D5338 (50°C) | GB/T 19277 (50°C) | Three-Zone Temperature Control Certification (50/58/65°C) |

| Ecotoxicity Limits (mg/kg) | Cd<0.5, Pb<50 | Cd<1.0, Pb<100 | Cd<3.0, Pb<300 | Bioavailability-Based Graded Assessment |

3.3 Recycling Diversion Dilemma

- Pain Points: Biodegradable materials mixed into traditional plastic recycling streams reduce the strength of recycled materials by 40%

- Solutions:

- Fluorescent Tracer Technology: BASF adds rare earth organic markers for UV identification and sorting

- Blockchain Traceability: IBM Food Trust system tracks the entire lifecycle of wiring harnesses

4. Industrial Synergy Barriers: The Island Effect and Trust Crisis

4.1 Material-Device Compatibility Impasse

| Production Stage | Traditional Equipment Pain Points | Innovative Solutions |

|---|---|---|

| Extrusion Molding | Insufficient PLA melt strength leading to breakage | • Shallow-screw design (L/D=32:1) • Melt gear pump for pressure stabilization |

| Injection Molding | Slow PBS crystallization (50% longer cycle time) | • Pulsed cooling technology (cycle reduced to 22s) |

| Coating Process | High PHA viscosity affecting leveling | • Supercritical CO₂ viscosity reduction (viscosity ↓80%) |

4.2 Chain of Trust Deficit

- Car Companies’ Doubts: Mercedes-Benz rejects it for “unwilling to tolerate a 0.1% failure risk in wiring harnesses”

- Ice-Breaking Actions:

- Accelerated Aging Database: UL establishes 100,000 sets of eco-friendly wiring harness failure models

- Insurance Mechanism: Munich Re introduces degradation material quality insurance

5. Four-Dimensional Technical Response Matrix

Benchmark Practices:

- Material Gene: Dow Chemical uses AI to screen the optimal PLA/PBAT/cellulose nanocrystal ratio, reducing R&D cycles from 5 years to 8 months

- Financial Empowerment: Goldman Sachs’ $500 million investment in biodegradable wiring harness companies, with carbon credit revenues accounting for 35% of profits

Breakthrough Templates: Technical Validation in Extreme Environments

| Scenario | Challenge | Solution | Validation Result |

|---|---|---|---|

| Dubai High-Temperature Wiring Harness | Ground temperatures of 70°C | sc-PLA + aerogel insulation layer | Maintains 90% performance at 125°C/2000h aging |

| Alaska Oil Pipelines | Brittle at -50°C | PCL/rubber composite sheath | Impact toughness maintained at 85% at -60°C |

| Cardiac Pacemaker Leads | Uncontrolled degradation rate in vivo | Enzyme activity shielding coating (pH=7.4 inactivated) | Degradation error <7 days over 18 months |

Conclusion: Pioneering a Path on the Edge of the Blade

The challenges faced by eco-friendly wiring harnesses are essentially collisions between industrial civilization and ecological laws. The response must transcend technology itself:

- Using bio-manufacturing to counter petroleum hegemony (synthetic biology reconstructs the material base)

- Using digital networks to bridge systemic gaps (blockchain + IoT builds a circular ecosystem)

- Using financial innovation to flatten the cost cliff (carbon monetization creates a new economic model)

When every biodegradable wiring harness serves as both an electrical current conduit and a carbon cycle carrier, humanity will truly grasp the code for coexistence between technology and the planet. This breakthrough battle leaves no room for retreat—either become a pioneer of ecological civilization or a relic of the plastic era.

Leave a Comment