Quality Control

At KABOLUX, we prioritize quality control throughout the production process of wire harnesses and cables. Our comprehensive quality control system ensures that every product meets the highest standards of performance, reliability, and safety. Here’s an introduction to our quality control measures for wire harnesses and cables:

I. Incoming Raw Material Inspection

Supplier Qualification & Evaluation

We carefully select and evaluate suppliers of wires, cables, terminals, and connectors. Suppliers must provide detailed material specifications, certifications, and quality assurance documents to ensure the raw materials meet our quality requirements.

Material Quality Testing

We conduct rigorous testing on incoming raw materials, including electrical conductivity tests, insulation resistance tests, and mechanical strength tests. We also inspect the appearance of the materials to ensure there are no defects such as scratches, cracks, or deformation that could affect product quality.

II. Production Process Monitoring

Wire Cutting & Stripping

During wire cutting, we use high - precision equipment to ensure the length accuracy of the wires. After cutting, we inspect the wire ends to ensure there are no burrs or damage. In the wire stripping process, we carefully control the stripping length and ensure the insulation layer is stripped cleanly without damaging the conductor.

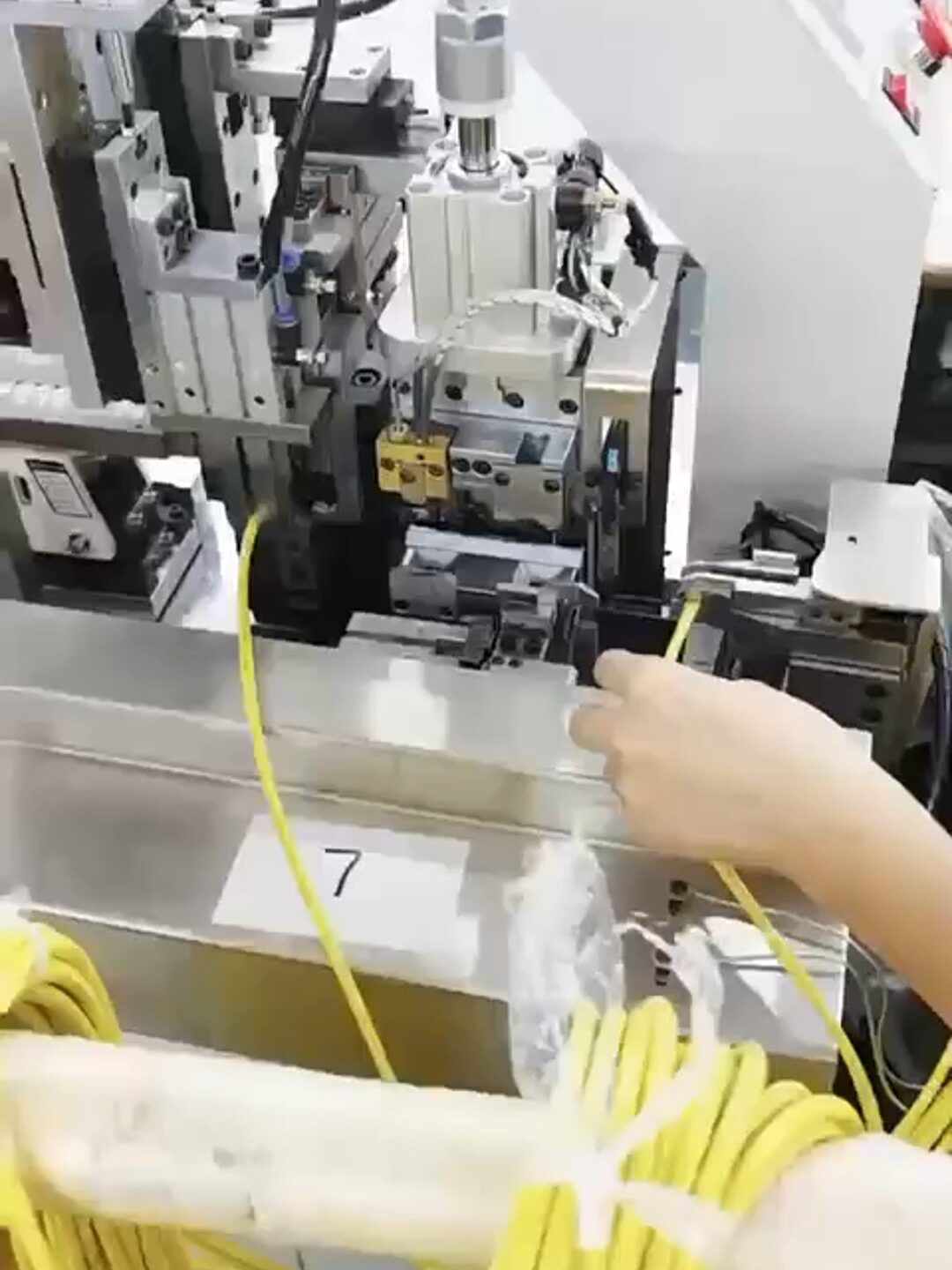

Crimping Process Control

We use advanced crimping equipment and regularly maintain and calibrate it to ensure the crimping quality of terminals and connectors. Our trained operators strictly follow crimping procedures, and we conduct real - time monitoring of crimping parameters such as pressure and height to ensure stable and reliable crimping quality.

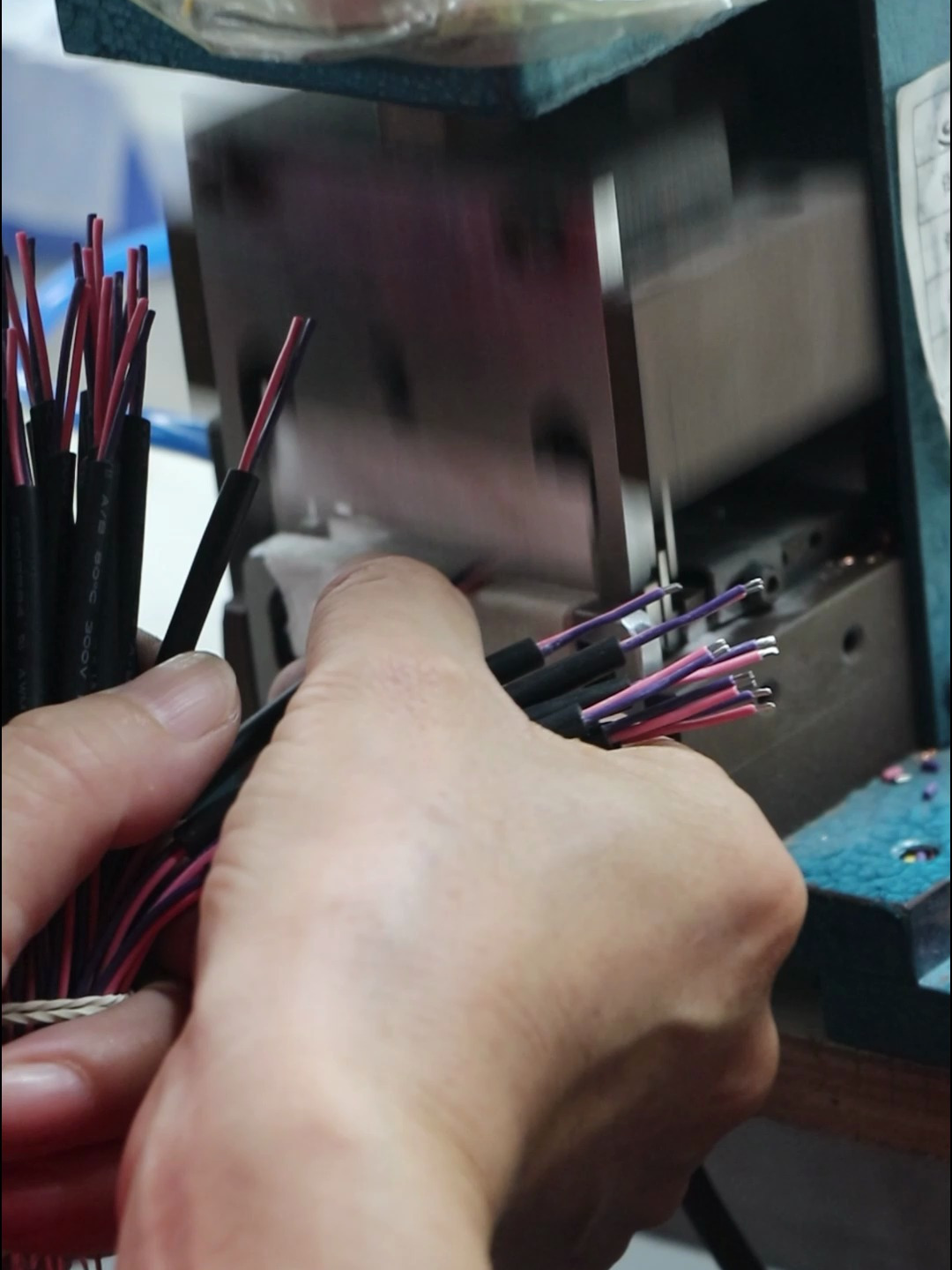

Assembly & Soldering

In the assembly process, we ensure that components are correctly and securely assembled. For soldering connections, we control soldering temperature, time, and solder quantity to ensure strong and conductive solder joints. We also perform visual inspections and necessary electrical tests on soldered joints to identify and correct any issues promptly.

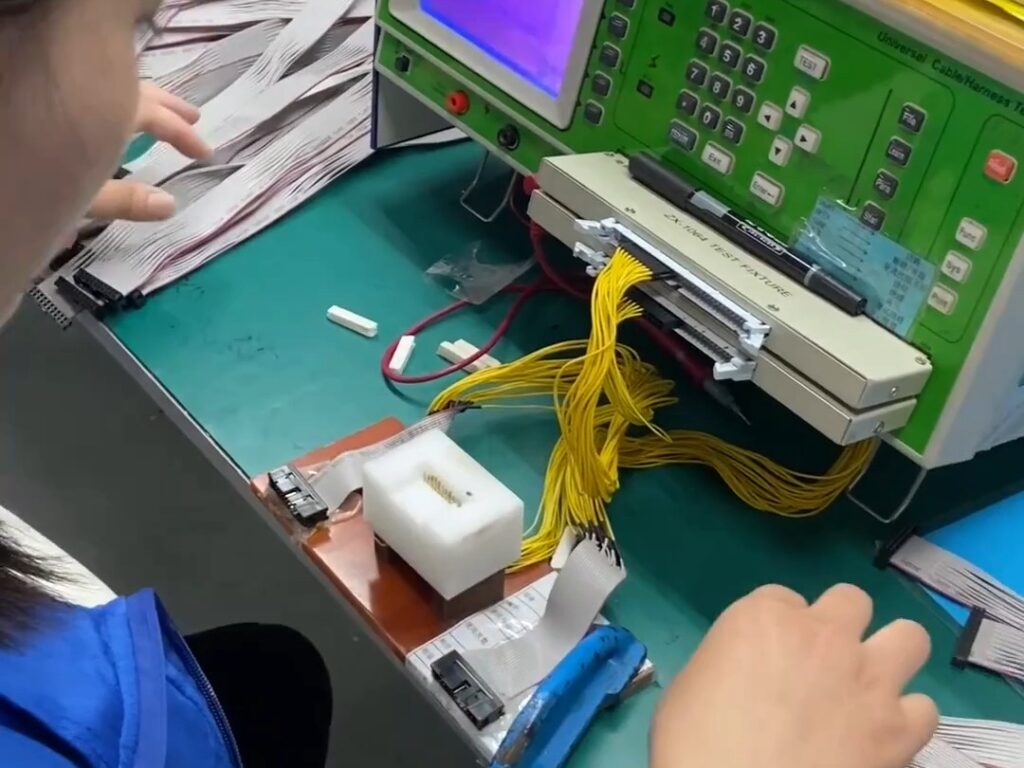

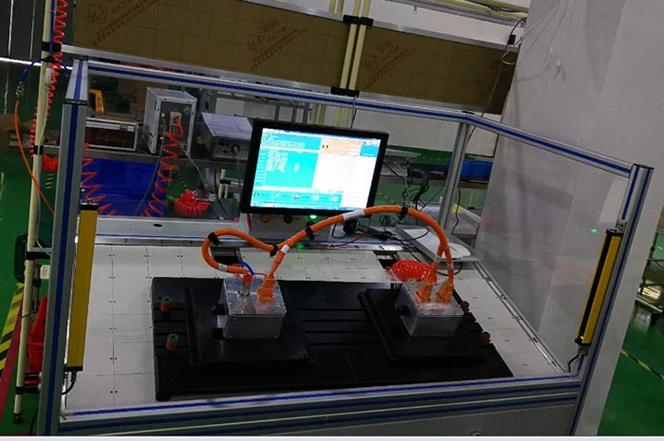

III. Finished Product Testing

Electrical Performance Testing

Mechanical Performance Testing

Environmental Performance Testing

IV. Quality Control for Cables

Dimensional Inspection

Insulation & Sheath Material Testing

Conductor Performance Testing

V. Quality Assurance for Wire Harnesses

100% Inspection

Process Control & Improvement