Application of Nanomaterials in Wiring Harnesses

With the trend of electronic devices towards miniaturization, intelligence, and high performance, traditional wiring harnesses face significant challenges in terms of conductivity, mechanical strength, and environmental adaptability.

With the trendWith the trend of electronic devices towards miniaturization, intelligence, and high performance, traditional wiring harnesses face significant challenges in terms of conductivity, mechanical strength, and environmental adaptability.

Nanomaterials, due to their unique physicochemical properties, have brought revolutionary breakthroughs to wiring harness technology.

Table of contents

Ⅰ. Enhancement of Conductivity

In wiring harnesses (such as cables, wires, and connectors), conductivity is one of the key performance indicators, directly affecting energy transmission efficiency and signal integrity.

Although traditional metal conductors (e.g., copper, aluminum) exhibit good conductivity, they still have limitations in miniaturization, high-frequency transmission, and extreme environments.

Due to their unique electrical properties (e.g., high current-carrying capacity, low resistivity, quantum effects), nanomaterials can significantly improve the conductivity of wiring harnesses.

1.1 Nanometallic Materials

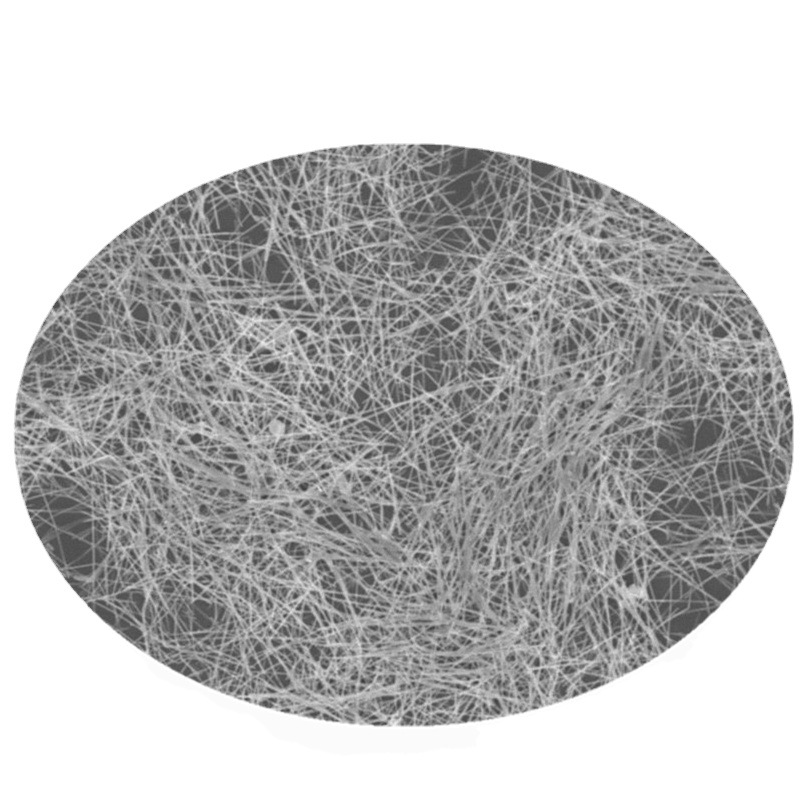

Nanometals (e.g., silver or copper nanoparticles/nanowires) exhibit superior conductivity compared to bulk metals due to their high specific surface area and quantum confinement effects.

For example, silver nanowires have conductivity close to pure silver and can form transparent conductive networks on flexible substrates, making them suitable for high-precision wiring harnesses.

| Material | Characteristics | Applications |

| Silver Nanowires | Low resistivity (~1.59×10⁻⁸ Ω·m), bendable, suitable for micro-wires | Flexible electronics, wearable device wiring |

| Copper Nanoparticles | Lower cost than silver, oxidation can be reduced via surface modification | High-density PCB wiring, automotive harnesses |

| Gold Nanocoatings | Oxidation-resistant, ideal for high-frequency signal transmission | Aerospace wiring, high-speed communication cables |

1.2 Carbon-Based Nanomaterials

Carbon nanotubes (CNTs) and graphene exhibit extremely high carrier mobility (graphene up to 200,000 cm²/V·s), making them ideal for high-frequency and high-conductivity applications.

• Carbon Nanotubes (CNTs): Single-walled CNTs can carry current densities up to 10⁹ A/cm², far exceeding copper (~10⁶ A/cm²), making them suitable for superconducting or high-current wiring.

• Graphene: As a conductive additive (e.g., graphene/copper composites), it reduces contact resistance and enhances signal transmission efficiency in high-frequency applications (e.g., 5G, mmWave radar wiring).

1.3 Nanocomposite Conductors

By combining nanomaterials (e.g., CNTs, graphene) with traditional metals, conductivity can be optimized:

• Copper-Graphene Composite: Increases conductivity by 10%~20% compared to pure copper while enhancing mechanical strength.

• Aluminum-CNT Wires: Reduce weight, making them suitable for aerospace wiring.

1.4 Application Cases

• New Energy Vehicles: Tesla uses silver nanowire-coated high-voltage wiring harnesses to reduce resistance and improve high-temperature resistance.

• Consumer Electronics: Apple patents indicate that CNTs can be used in miniaturized Lightning connector designs.

1.5 Challenges

Despite their excellent conductivity, nanomaterials still face challenges:

• Cost: Large-scale production of silver nanowires and graphene remains expensive.

• Stability: Nanometals (e.g., copper nanowires) are prone to oxidation and require surface coating.

• Process Compatibility: Uniform dispersion of nanomaterials in wiring harness manufacturing requires further optimization.

▶ In the future, with advancements in nanomaterial production, wiring harnesses with superior conductivity and lower costs are expected to see widespread use in high-end electronics, new energy vehicles, and aerospace applications.

Ⅱ. Lightweight and Strength Enhancement

In wiring harnesses (sIn modern electronic devices, new energy vehicles, and aerospace applications, there is an increasing demand for lightweight and high-strength wiring harnesses.

InAlthough traditional metal conductors (such as copper and aluminum) have good conductivity, their high density and limited mechanical strength pose challenges.

Nanomaterials, with their unique mechanical properties (such as ultra-high strength, low density, and high toughness), can significantly improve the lightweight and strength characteristics of wiring harnesses.

2.1 Lightweight Advantages of Nanomaterials

Nanomaterials (such as carbon nanotubes, graphene, and nanofibers) have extremely low density and high specific strength (strength-to-weight ratio), which can partially or completely replace traditional metal wires, significantly reducing the weight of wiring harnesses.

| Material | Density (g/cm³) | Tensile Strength (GPa) | Specific Strength (Strength/Density) | Application Scenarios |

| Copper (Traditional Material) | 8.96 | 0.2~0.3 | ~0.03 | Conventional cables, power harnesses |

| Carbon Nanotubes (CNTs) | 1.3~2.0 | 11~63 | ~30 | Aerospace, ultra-lightweight harnesses |

| Graphene Films | ~2.0 | 130 | ~65 | Flexible electronics, wearable device harnesses |

| Aramid Nanofibers | 1.44 | 3.0~3.6 | ~2.5 | High-strength tensile harnesses |

2.2 Nanomaterial-Reinforced Composite Harnesses

By combining nanomaterials with traditional polymers or metals, new types of harnesses that are both lightweight and high-strength can be produced:

• CNT-reinforced copper wires: 30% lighter than pure copper with 50% increased strength, suitable for automotive high-voltage harnesses.

• Graphene-aluminum composites: 20% lighter than traditional aluminum wires with improved fatigue resistance, ideal for aerospace harnesses.

• Aramid nanofiber-coated wires: Maintain flexibility while increasing tensile strength by 3 times, used for robotic dynamic harnesses.

2.3 Application Cases

• New energy vehicles: BMW uses CNT-reinforced aluminum wires, reducing battery harness weight by 15% while improving vibration resistance.

• Aerospace: Boeing 787 uses graphene composite wires, reducing cabin harness weight by 20% and improving fuel efficiency.

• Consumer electronics: Huawei patents show CNT fibers can be used in flexible circuits for foldable smartphones, 40% lighter than traditional copper wires.

2.4 Challenges and Future Directions

• Dispersion process: Uniform dispersion of nanomaterials in matrices remains challenging.

• Cost control: Large-scale production costs of CNTs and graphene need further reduction.

• Long-term reliability: Performance stability of nanocomposite harnesses in extreme environments (e.g., high/low temperatures, radiation) requires verification.

▶ In the future, with the maturation of nanocomposite technologies, lightweight and high-strength nanomaterial-based harnesses will play a greater role in electric vehicles, smart wearables, and space exploration.

Ⅲ. High Temperature and Corrosion Resistance

In high-temperature, humid, or chemically corrosive environments, conventional wiring harnesses are prone to aging and insulation failure.

Nanomaterials can significantly improve the high-temperature and corrosion resistance of wiring harnesses through their unique structural characteristics (such as high melting points, chemical inertness, and dense protective layers).

3.1 High-Temperature Resistant Nanomaterials

| Material | Temperature Range (°C) | Advantages | Application Scenarios |

| Carbon Nanotubes (CNTs) | -200~1000 | Excellent high-temperature stability, high thermal conductivity | Engine compartment wiring, aerospace cables |

| Graphene Coating | -269~400 | Anti-oxidation, reduces conductor heating | High-voltage wiring for EV batteries |

| Nano-ceramics (Al₂O₃) | Up to 1600 | Excellent insulation, resistant to arc erosion | High-temperature industrial equipment cables |

3.2 Nano-Corrosion Resistance Technologies

• Graphene protective layer: Blocks water and oxygen, extending copper wire’s salt spray test lifespan by 5 times, suitable for marine equipment wiring.

• Nano-SiO₂ modified insulation layer: Enhances polymer’s acid/alkali resistance, used in chemical industry cables.

3.3 Application Cases

• Automotive: Tesla uses nano-ceramic coated wiring harnesses to withstand high-temperature battery environments.

• Aerospace: NASA uses carbon nanotube-polyimide composites in Mars rover wiring to withstand extreme temperatures and radiation.

3.4 Challenges

▶ Challenges remain in optimizing coating uniformity and performance degradation under prolonged high temperatures. Self-healing nano-coating technology may become a breakthrough solution in the future.

Ⅳ. Flexible Harnesses and Wearable Devices

With the rapid development of flexible electronics and wearable devices, traditional rigid wiring harnesses can no longer meet the requirements for repeated bending and stretching.

Nanomaterials have become the ideal choice for flexible wiring harnesses due to their excellent flexibility, high conductivity, and mechanical durability.

4.1 Comparison of Flexible Nano-Conductive Materials

| Material | Characteristics | Application Scenarios |

| Silver Nanowires | High conductivity, stretchability up to 200% | Flexible displays, smart clothing wiring |

| Graphene Films | Ultra-thin (monoatomic layer), good light transmittance | Transparent electrodes, flexible sensor wiring |

| Liquid Metals | Self-healing properties, no fracture under extreme deformation | Internal connections for stretchable electronic devices |

| Carbon Nanotube Fibers | High strength, withstands over 100,000 bends | Medical electronics, bionic robot wiring |

4.2 Key Technological Breakthroughs

• Stretchable Structure Design: Serpentine or spiral arranged nano-wires can achieve 300% stretchability (e.g., used in smart bracelet monitoring wires).

• Nano-Conductive Composites: Combining silver nanowires with elastomers (PDMS) to balance conductivity and flexibility.

4.3 Typical Applications

• Medical Field: Graphene-elastomer wiring used in ECG patches, skin-friendly and resistant to sweat corrosion.

• Consumer Electronics: Samsung’s foldable smartphones use carbon nanotube flexible circuits with over 200,000 bending cycles.

4.4 Challenges

▶ The interfacial bonding strength between nanomaterials and substrates, as well as resistance stability after repeated deformation, still need optimization. In the future, self-powered flexible wiring (e.g., piezoelectric nanomaterials) may become a research direction.

Ⅴ. Smart Harnesses and Self-healing Functions

With the development of smart devices, IoT and advanced manufacturing technologies, traditional wiring harnesses are evolving towards intelligent and self-healing directions.

Nanomaterials provide innovative solutions for smart harness development through their unique sensing characteristics and dynamic chemical bonding capabilities.

5.1 Intelligent Sensing and Monitoring Functions

Nanomaterials can enable real-time monitoring capabilities in wiring harnesses, allowing them to sense parameters like temperature, strain, and damage.

| Nano-sensing Materials | Detection Parameters | Response Characteristics | Typical Applications |

| Carbon Nanotube Films | Strain/Pressure | Highly sensitive resistance change (GF>100) | Structural health monitoring harnesses |

| Quantum Dot Coatings | Temperature | Fluorescence intensity varies with temperature | Battery pack temperature monitoring harnesses |

| Graphene Fibers | Crack Propagation | Impedance mutation response (<1ms) | Critical circuit monitoring in aircraft |

5.2 Self-healing Nanomaterial Technologies

Through nanomaterial design, harnesses can automatically restore conductivity or mechanical strength after damage:

• Microcapsule Repair Systems:

▪Nanocapsules containing liquid metal/conductive polymers embedded in insulation layers release healing agents when ruptured (repair efficiency >90%).

▪Applications: Automotive harness wear repair, deep-sea cable protection.

• Dynamic Bonding Materials:

| Material Type | Healing Mechanism | Trigger Condition | Recovery Rate |

| Diels-Alder Polymers | Reversible chemical bond reorganization | Heating (80-120°C) | 85% |

| Metal-Ligand Complexes | Dynamic coordination bond breakage/regeneration | Room temperature or mild heating | 95% |

5.3 Application Cases

• New Energy Vehicles: BYD uses carbon nanotube sensing harnesses to monitor abnormal heating in high-voltage circuits in real-time.

• Aerospace: Airbus A350 uses microcapsule self-healing harnesses to improve wing circuit reliability.

• Electronic Skin: University of Tokyo developed graphene-hydrogel self-healing wires that restore conductivity within 5 minutes after tensile fracture.

5.4 Technical Challenges and Development

• Precise Triggering: Need to optimize controllability of self-healing conditions (e.g., light/heat/electric triggers).

• Cycle Life: Current materials typically only support 3-5 effective repairs.

• Integration Process: How to incorporate sensing/self-healing functions into traditional harness manufacturing processes.

▶ In the future, with the integration of AI and nanomaterials, fourth-generation smart harnesses with predictive maintenance capabilities will become key components of Industry 4.0.

Ⅵ. Insulation and Electromagnetic Shielding

In modern electronic systems, the insulation performance and electromagnetic shielding capability of wiring harnesses directly affect equipment reliability and signal integrity.

Nanomaterials provide breakthrough insulation and shielding solutions for wiring harnesses through their unique dielectric properties and electromagnetic wave absorption mechanisms.

6.1 Nano Insulation Materials

Nanomaterials can significantly improve the performance of traditional insulation materials:

• Precise Triggering: Need to optimize controllability of self-healing conditions (e.g., light/heat/electric triggers).

| Material Type | Dielectric Strength(kV/mm) | Volume Resistivity(Ω·cm) | Thermal Conductivity(W/m·K) | Main Advantages |

| Traditional PVC | 15-20 | 10^14-10^16 | 0.16-0.22 | Low cost, good processability |

| Nano-SiO₂ Modified | 25-35 | 10^16-10^18 | 0.35-0.45 | 50% improvement in temperature resistance |

| Boron Nitride Nanosheets | 40-50 | >10^18 | 20-30 | Ultra-high thermal conductivity insulation |

| Nanocellulose | 30-40 | 10^15-10^17 | 0.8-1.2 | Biodegradable |

Table: Performance comparison of typical nano insulation materials

6.2 Nano Electromagnetic Shielding Technology

Nanomaterials achieve excellent electromagnetic shielding effectiveness (SE) through multiple mechanisms:

• Conductive Network Type:

Carbon nanotube (CNT) filling: 3-5wt% addition can achieve 30-40dB shielding effect

Graphene coating: 0.1μm thickness can achieve over 25dB shielding

• Wave Absorption Type:

Ferrite nanoparticles: Particularly suitable for GHz frequency interference suppression

Core-shell nanostructures: Broadband absorption characteristics

| Shielding Material | Thickness(mm) | Shielding Effectiveness(dB) | Main Frequency Band | Application Scenarios |

| Copper Foil (Traditional) | 0.05 | >60 | Full frequency band | Ordinary cables |

| 5%CNT/PP | 0.5 | 35-45 | 1-10GHz | Automotive wiring harnesses |

| Graphene Composite Film | 0.02 | 25-30 | 10-100GHz | High-frequency signal lines |

| Fe₃O₄@C Nano | 0.3 | 40-50 | 2-18GHz | Military equipment |

Table: Performance comparison of typical nano shielding materials

6.3 Application Cases

• New Energy Vehicles:

Tesla battery pack wiring harness uses boron nitride nanosheet modified insulation layer, improving thermal conductivity by 10 times

FBYD uses CNT-filled shielding layer, reducing wiring harness weight by 30%

• 5G Communication:

Huawei base stations use graphene-shielded jumper cables, achieving 35dB shielding effectiveness at 28GHz frequency band

• Aerospace:

Boeing 787 uses nanocellulose insulation materials, reducing weight by 15% and improving arc resistance

6.4 Technical Challenges

• Dispersion Uniformity: Nanoparticles tend to agglomerate, affecting performance consistency

• Cost Control: Production costs of high-quality nanomaterials remain relatively high

• Long-term Reliability: Aging mechanisms of nanomaterials in harsh environments like humidity and heat are not yet clear

Future development trends include:

Smart responsive insulation materials (temperature/pressure sensitive)

Multifunctional integrated design (insulation + shielding + heat dissipation)

Development and application of environmentally friendly nanomaterials

▶ Nano insulation and shielding technologies are driving wiring harnesses towards lighter, thinner and smarter directions, providing critical support for next-generation electronic devices.

No comments to show.

Leave a Comment