Cold Crimping vs Hot Crimping/Staking, Which is Better?

Table of contents

I. Core Principle Differences

Cold Crimping

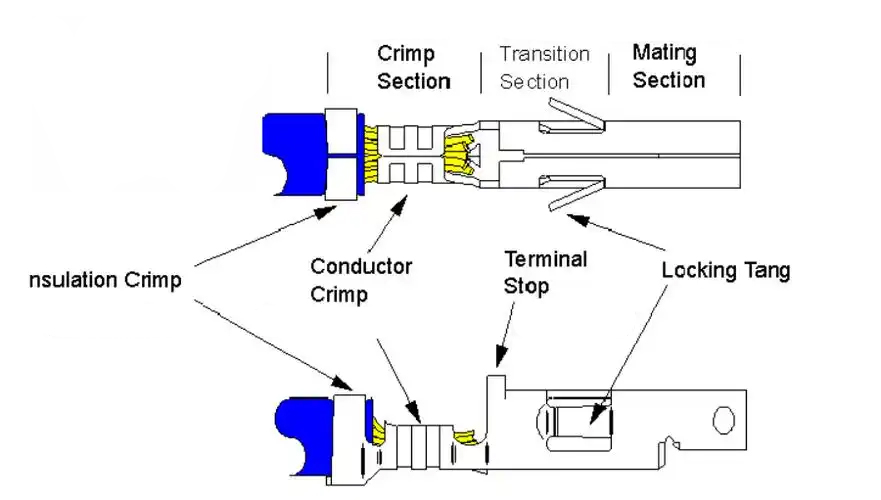

Performed at ambient temperature (typically room temperature), this process applies high pressure (usually in the range of 10–25 MPa) to the connection point. This forces the metal conductor or connector terminal (e.g., copper sleeve, terminal) to undergo plastic deformation, tightly wrapping and compressing the wire or components to be joined. This deformation eliminates air gaps at the contact interface, creating a mechanical interlock and intimate physical contact, thereby achieving electrical conductivity and mechanical fixation. No heating is involved. The key to success lies in applying sufficient pressure to cause permanent deformation and tight conformity, while precisely controlling the pressure to avoid damaging the wire or terminal. Surface cleaning to remove oxides and contaminants is usually required prior to crimping.

Hot Crimping / Hot Staking

This process involves applying heat to the connection point simultaneously with or prior to the application of pressure. The heating temperature typically ranges from 80–200°C or higher, depending on the material and specific process. Heat sources can include direct conduction (e.g., heated dies), ultrasonic energy, resistance heating, or lasers. Heat plays several critical roles:

- (1) Softening or melting specific components within the metal or connector (e.g., solder, plastic stakes, insulation)

- (2) Promoting molecular diffusion, enabling metallurgical bonding (e.g., intermetallic compound formation) or fusion (e.g., plastics) at the contact interface on an atomic/molecular level;

- (3) Reducing the yield strength of the material, allowing effective deformation and bonding to occur at lower pressures (typically in the range of 5–15 MPa) compared to cold crimping. Hot crimping/staking is fundamentally a controlled thermo-mechanical process designed to create a stronger, lower-resistance, and more reliable connection than a purely mechanical joint.

Summary of Core Principle Differences

| Feature | Cold Crimping | Hot Crimping/Staking |

|---|---|---|

| Temperature | Ambient/Room Temp | Heated – 80°C to 200°C+ |

| Pressure | High – 10-25 MPa | Medium-Low – 5-15 MPa |

| Energy Source | Pure Mechanical Energy | Thermal + Mechanical Energy |

| Bonding Mechanism | Mechanical Interlock/Plastic Deformation | Metallurgical Bonding/Molecular Diffusion/Melting Fusion |

| Key Action | High pressure causes permanent deformation | Heat softens/melts/promotes diffusion |

II. Key Performance Comparison

| Parameter | Cold Crimping | Hot Crimping/Staking |

|---|---|---|

| Joint Strength | • Moderate mechanical interlock: Relies on physical interlocking from plastic deformation; tensile strength ~150-350 MPa • Fretting wear risk in vibration environments (loosening rate >5%) • Typical scenario: Building cable terminals | • High-strength metallurgical bonding: Molecular diffusion forms metallic bonds; tensile strength reaches 300-600 MPa • Excellent vibration resistance (loosening rate <0.5%) • Typical scenario: Aerospace wire welding |

| Conductivity | • Higher contact resistance: Micron-scale air gaps (>2μm) increase initial resistance by 15-25% • Resistance rises over time due to oxidation (annual degradation rate: 3-8%) • Applicable to: Low-voltage household circuits (<60V) | • Near-zero resistance connection: Atomic-level bonding eliminates interfacial resistance; resistance reduction ≥20% • High stability (annual degradation rate <1%) • Applicable to: Power battery tabs (>400V) |

| Thermal Stability | • Prone to loosening at high temperatures due to CTE mismatch (>120°C failure risk↑) • Resistance variation >10% after thermal cycling (-40~85°C) • Extreme application: Automotive wiring harnesses (outside engine bays) | • Wide temperature tolerance (-196~300°C); diffusion layer suppresses thermal expansion • Resistance variation <3% after 1,000 thermal cycles (-40~120°C) • Extreme application: Motor stator windings |

| Process Efficiency | ★ High-speed & low-cost: 0.5-2 seconds per crimp; equipment cost <$10k ★ No temperature control needed; energy consumption <0.1kWh/point ★ Yield rate depends on operator skill (±15% fluctuation) | ★ Precision control: 3-8 seconds per point (incl. heating/cooling); equipment cost >$50k ★ Energy consumption: 0.5-2kWh/point (70% for temp. control) ★ Automated yield rate >99.5% (closed-loop parameter control) |

| Material Compatibility | ▲ Only suitable for ductile metals (copper, aluminum, etc.) ▲ Cannot join dissimilar materials (e.g., Cu-steel) ▲ Wire diameter limit: 0.5-120mm² | ▲ Supports multiple materials: Metals/plastics/ceramics (e.g., battery Al/Cu foil) ▲ Welds dissimilar metals (Cu-Ni diffusion layer) ▲ Ultra-thin material compatibility: Li-ion battery electrodes (0.1mm) |

Limitations Comparison

| Risk Type | Cold Crimping | Hot Crimping/Staking |

|---|---|---|

| Process Defect | ■ Under-crimping: Poor contact causes overheating (ΔT>30°C) ■ Over-crimping: Wire core fracture (strength↓50%) | ■ Excessive temperature: Grain boundary damage (e.g., copper embrittlement) ■ Heat-affected zone (HAZ) expansion |

| Environmental Limits | × Accelerated oxidation in humid environments (resistance↑20% after 48h salt spray test) × Unsuitable for extreme temperatures | × High-temp. operations require explosion-proof design (e.g., battery workshops) × High thermal management costs |

Conclusion Guidance

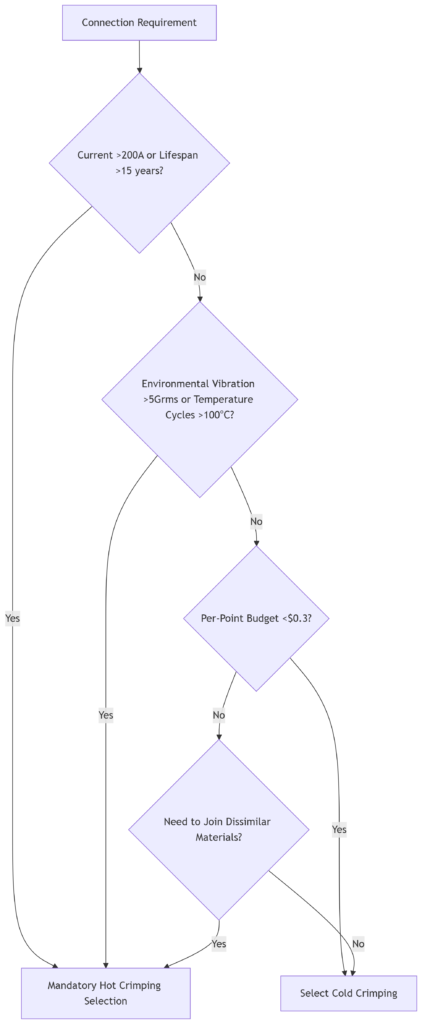

✅ Choose cold crimping when: Cost-sensitive + Non-extreme environments + Medium-low current (e.g., appliance wiring/low-voltage distribution)

✅ Choose hot crimping/staking when: High-reliability requirements + Wide temp./vibration range + High conductivity needs (e.g., EV batteries/aerospace electronics)

🔥 Core difference:

Cold Crimping = Mechanical Interlock → Economic physical connection

Hot Crimping/Staking = Metallurgical Bonding → High-performance chemical-bond connection

III. Application Scenario Analysis

Optimal Scenarios for Cold Crimping

| Application Field | Technical Rationale | Typical Example |

|---|---|---|

| Building Electrical Wiring | • High Safety: No sparks/high heat, compliant with fire codes • Cost Efficiency: 0.5 sec/point, labor cost <$0.1/point • Large Cross-Section Support: Handles 300mm² copper cable terminals | Terminal connections in residential distribution panels (Chinese GB/T 2099 Standard) |

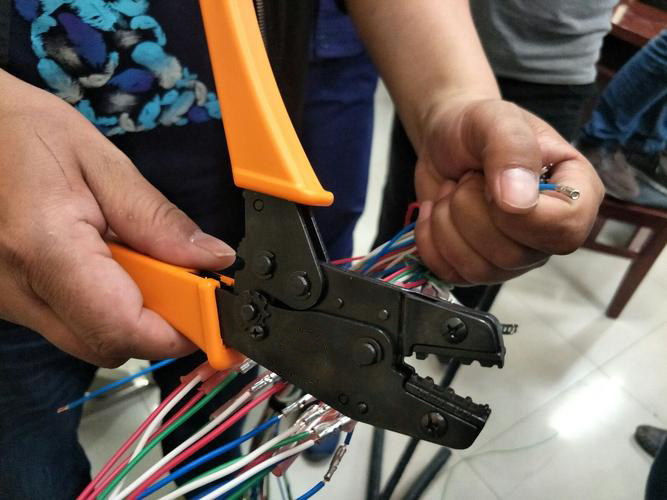

| Low-Voltage Device Harnesses | • Voltage Compatibility: No arc risk in <60V systems • Flexible Production: Operable with handheld crimpers • Easy Maintenance: Mechanically detachable for rework | Internal wiring in appliances (refrigerators/washing machines) |

| Cost-Driven Mass Production | • Low Equipment Investment: Crimping machines <$5,000 • Negligible Energy Use: ≈0.05kWh/1,000 points • No Environmental Controls: No exhaust/thermal systems needed | Consumer electronics charging cables (USB-C terminals) |

Irreplaceable Scenarios for Hot Crimping/Staking

| Application Field | Technical Rationale | Typical Example |

|---|---|---|

| Power Battery Manufacturing | • Zero-Resistance Requirement: Tab resistance <0.1mΩ (cycle life ↑30%) • Ultra-Thin Material Handling: 0.1mm aluminum foil without tearing (cold crimp damage rate >15%) • Interfacial Diffusion: Cu/Al molecular bonding prevents galvanic corrosion | CATL 4680 battery tab welding |

| High-Reliability Motors | • Vibration Resistance: Metallurgical bonding withstands 15,000rpm centrifugal force • Temperature Endurance: H-class insulation (180°C) for enamel wire fusion • Space Savings: No terminal volume, power density ↑20% | Tesla motor stator hairpin welding |

| Dissimilar Material Joining | • Surface Activation: Heat breaks oxide layers (e.g., Al-Cu) • Enhanced Plasticity: Heating reduces yield strength, pressure ↓50% • Composite Structuring: Metal-plastic co-forming (automotive sensors) | BYD Blade Battery aluminum laminate encapsulation |

Scenario Decision Matrix

| Key Dimension | Cold Crimping Preferred Conditions | Hot Crimping Mandatory Conditions |

|---|---|---|

| Cost Constraint | Per-point budget <$0.2 | Per-point budget >$1.5 (equipment amortized) |

| Current Level | <100A | >200A (prevent Joule heating failure) |

| Environmental Severity | Temp: -20~85°C Humidity: <85%RH | Temp: -40~150°C Vibration: >5Grms |

| Lifecycle Demand | <10 years (appliance-grade) | >15 years (automotive-grade/aerospace) |

IV. Process Defects and Risks

Critical Defects in Cold Crimping

| Defect Type | Failure Mechanism | Industry Validation Data |

|---|---|---|

| Under-Crimping | • Micro-gap conduction: Insufficient metal deformation → contact resistance surges • Local overheating: ΔT>80℃ at 100A current (3× exceeding national standards) • Arcing risk: Gap breakdown voltage <300V | 32% of automotive wiring harness failures stem from insufficient crimp force (SAE J2683 validated) |

| Over-Crimping | • Wire core shearing: Pressure exceeds yield limit → conductor cross-section ↓40% • Terminal cracking: Copper alloy stress corrosion (crack propagation rate: 0.1mm/1k vibrations) • Fatigue failure: Service life <500 hours under vibration (automotive standard >2000h) | Aviation connector rework case: Over-crimping reduced pin fracture strength by 63% (NASA 8739.4) |

| Interface Oxidation | • Time-dependent resistance growth: Cu/Al interface corrosion rate >5μm/year • Thermal cycling failure: Resistance ↑200% after -40℃~125℃ cycles • Salt spray corrosion: Conductive failure after 48h test (ISO 9227) | Coastal wind power project: 18% failure rate for cold-crimped terminals over 5 years (IEC 61439 report) |

High Risks in Hot Crimping/Staking

| Risk Type | Failure Mechanism | Industry Disaster Case |

|---|---|---|

| Thermal Runaway | • Local overheating: Temperature control failure → material ignition triggered (copper: 1083℃) • Chain reaction: Battery tab overheating → separator melt-through (>130℃) • Toxic gas: PVC insulation decomposes releasing HCl (IDLH concentration 50ppm) | 2023 battery factory fire: $130M loss from PID control failure in hot press (NFPA report) |

| Microstructural Degradation | • Grain coarsening: Recrystallization temperature exceeded → copper embrittlement (ductility ↓70%) • Intermetallic compounds: CuAl₂ brittle layer at Al/Cu interface (hardness HV>300) • Residual stress: Cooling rate >50℃/s causes cracking (fatigue strength ↓45%) | Satellite power module failure: Orbital fracture due to excessive IMC thickness (ESA ECSS standard) |

| HAZ Damage | • Insulation failure: Carbonization of enamel wire polyamide layer (withstand voltage <500V) • Substrate deformation: PCB delamination/blistering (Tg>170℃ material CTE mutation) • Seal failure: Molecular chain degradation in plastic stakes (tensile strength ↓60%) | Pacemaker recall: Body fluid leakage through HAZ in hot-staked encapsulation (FDA MAUDE database) |

Process Control Red Zones

| Parameter | Cold Crimping Tolerance | Hot Crimping Tolerance | Out-of-Control Consequence |

|---|---|---|---|

| Pressure | ±8% (ISO 14372) | ±5% (IPC-610H) | Cold: Over-pressure → terminal cracks Hot: Under-pressure → cold joints (X-ray detection rate <30%) |

| Temperature | N/A | ±3℃ (IATF 16949) | Hot: +10℃ → IMC thickness ↑50% -10℃ → bond strength ↓40% |

| Time | ±100ms (MIL-DTL-22520) | ±0.5s (JIS C9715) | Cold: Overtime → work hardening embrittlement Hot: Overtime → HAZ expands 3× |

Risk Mitigation Technologies

- Cold Crimping:

✅ Optical inspection: AOI monitors indentation depth in real-time (±0.01mm)

✅ Force-displacement curve: PLC controls pressure peaks (e.g., KUKA CrimpTronic)

✅ Anti-oxidation coating: Tin/silver plating (salt spray life 5× longer) - Hot Crimping:

🔰 Multi-thermocouple control: 16-point temperature uniformity (±1℃)

🔰 Ultrasonic monitoring: 20MHz sensors track molecular diffusion

🔰 Inert gas protection: N₂ atmosphere welding (O₂ content <50ppm)

Critical Warning

⚠️ Cold crimping’s greatest risk: Latent Failure – Passes initial tests but fails suddenly due to vibration/oxidation

⚠️ Hot crimping’s fatal flaw: Domino Effect – Single-point thermal runaway triggers system conflagration

🔥 Industry’s hard-won rule:

Cold crimping defect cost = Recall expenses × Brand damage × Safety fines

Hot crimping accident cost = Production line loss + Environmental compensation + Criminal liability

V. Comprehensive Recommendations

Selection Decision Tree

Industry Golden Rules

| Scenario | Cold Crimping Standards | Hot Crimping Standards |

|---|---|---|

| Automotive Harness | • Crimp force control ±5% • Waterproof terminal tin plating >3μm • 100% pull test (>50N) | • Temperature control accuracy ±2℃ • IMC thickness <4μm (SEM inspection) • Helium leak rate <10⁻⁶ Pa·m³/s |

| Power Battery | ✘ Prohibited (except maintenance terminals) | • Tab resistance <0.05mΩ • Fusion depth 30-50% • In-line X-ray defect detection |

| Aerospace | △ Only auxiliary circuits △ Vacuum potting required | • Aerospace solder (Sn96.5Ag3.5) • >500 thermal cycles validation • Microgravity environment testing |

Future-Proofing Advice

| Technology Trend | Cold Crimping Strategy | Hot Crimping Strategy |

|---|---|---|

| High Voltage (>800V systems) | Phased out (voltage limit 600V) | ✅ Develop nano-silver sintering (withstand >3kV) |

| Miniaturization (<0.1mm wire diameter) | Precision die cost ↑300% | ✅ Laser-assisted micro-crimping (±5μm accuracy) |

| Sustainable Manufacturing | Copper terminal recycling >95% | ✅ Low-temperature hot pressing (<150℃) ↓energy 40% |

Final Selection Statement

✅ Choose cold crimping ONLY when:

▷ Budget constraints dominate (per-point cost <$0.2)

▷ Non-safety-critical systems (ASIL-A/B level)

▷ Static mild environments (Temp -20~85℃, Humidity <80%)

“Preferred solution for building distribution panels”

🔥 MUST choose hot crimping when:

▶ Zero-failure-tolerance scenarios (e.g., pacemakers/spacecraft power)

▶ High-strain conditions (Vibration >10Grms, Thermal shocks >200 cycles)

▶ Material innovation needs (e.g., carbon nanotube electrode connections)

“Cornerstone of power batteries and space exploration”

Cross-Era Insight

⚡ 20th Century Rule: Cold crimping covered 80% industrial connections (cost-driven)

⚡ 21st Century Shift: Hot crimping >70% in new energy/semiconductor fields (performance revolution)

⚡ Future Prediction: Molecular cold welding may unify both by 2040 (quantum tunneling crimping)

🔬 Engineering Philosophy:

Cold Crimping – Pinnacle of mechanical artistry

Hot Crimping – Alchemy of atomic reconstruction

Leave a Comment