Custom Cable Solutions

What is Custom Cabling?

Custom cables are engineered to meet unique specifications, allowing manufacturers to design cable assemblies tailored to specific needs. This customization ensures optimal performance and reliability in various applications. For cable assembly manufacturers, custom cabling means having the flexibility to create cables that precisely match the operational requirements of their products, whether it’s for industrial machinery, medical devices, or aerospace technology.

How Do You Manufacture a Cable?

Manufacturing a cable involves several crucial steps:

Wire Drawing: The process begins with wire drawing, where metal wires (typically copper or aluminum) are pulled through a series of dies to achieve the desired diameter, conforming to the American Wire Gauge (AWG) standards.

Annealing: Next, the wires undergo annealing, a heat treatment process that softens the metal, making it more flexible and less prone to breaking during subsequent manufacturing steps.

Twisting and Stranding: Multiple wires are twisted together to form strands, which are then twisted around each other to create a single cable. This process increases the cable’s strength and conductivity.

Extrusion: Insulation materials, such as PVC or polyethylene, are extruded around the wire strands. This insulation protects the wires and ensures the cable’s durability.

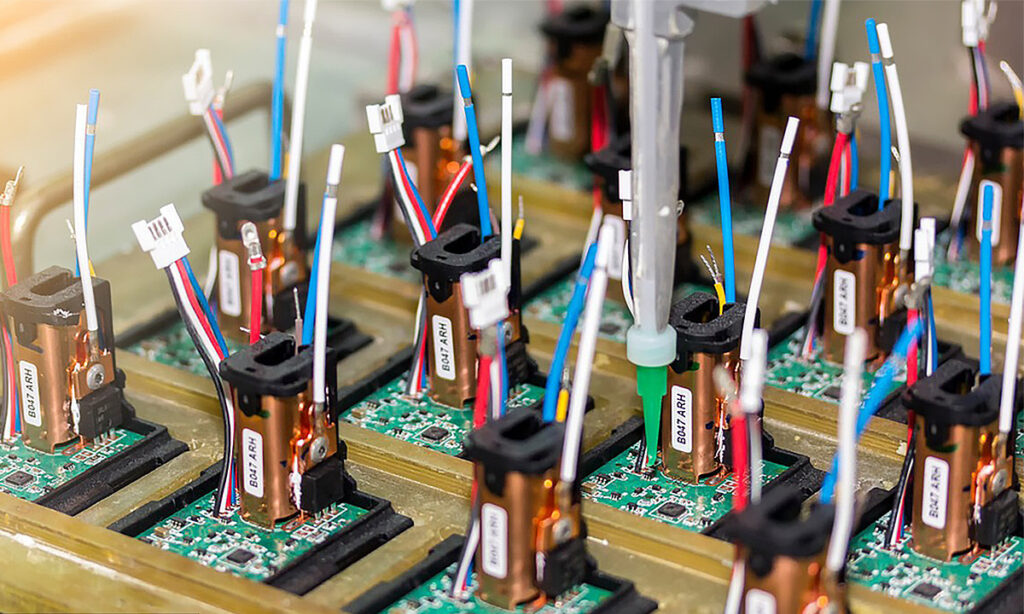

Cabling: Finally, multiple insulated wires are assembled into the final cable configuration. This stage may also include additional protective layers, such as shielding or jacketing, depending on the cable’s intended application.

When Installing Cable for a Building Management System, What is the Preferred Type of Cable?

Fiber optic cables are preferred for long-distance data transmission and high-speed connections in building management and security systems. They offer superior performance, higher bandwidth, and greater reliability compared to traditional copper cables. Fiber optic cables are ideal for connecting different buildings or remote locations within a complex, ensuring efficient and secure communication.

How Do You Measure Custom Cables?

To measure custom cables accurately, use a string or pipe cleaner to determine the distance between your power supply port and the port of the other component. Follow the intended route that the cable will take, including any bends or turns, to ensure the measurement reflects the actual length needed. This method helps prevent errors and ensures that the custom cable fits perfectly within its designated space.

What Are the Key Considerations for Custom Cable Solutions for Cable Assembly Manufacturers in the USA?

Manufacturers in the USA must consider several factors when designing custom cable solutions:

Regulatory Standards: Compliance with industry-specific standards, such as UL, RoHS, and ISO, is crucial to ensure safety and quality.

Availability of Materials: Access to high-quality materials, including conductors, insulation, and shielding, impacts the cable’s performance and longevity.

Specific Industry Requirements: Each industry may have unique demands, such as resistance to extreme temperatures, chemicals, or physical stress, which must be addressed in the cable design.

How to Find Custom Cable Solutions for Cable Assembly Manufacturers Near Me?

Local custom cable solutions can be found through various methods:

Industry Directories: Online directories and industry associations often list reputable manufacturers and suppliers.

Trade Shows: Attending trade shows and industry events provides opportunities to meet and network with custom cable manufacturers.

Online Platforms: Websites and platforms dedicated to connecting manufacturers with suppliers can help locate local custom cable solutions.

Top Custom Cable Assembly Manufacturers

Several top manufacturers specialize in custom cable assemblies, offering high-quality and reliable solutions for various industries. Some notable companies include:

CCSI: Known for their excellence in manufacturing engineered cable assembly solutions.

Amphenol