Differences between wire harnesses and cables and selection guide

Table of contents

▶ Definitions and Core Differences

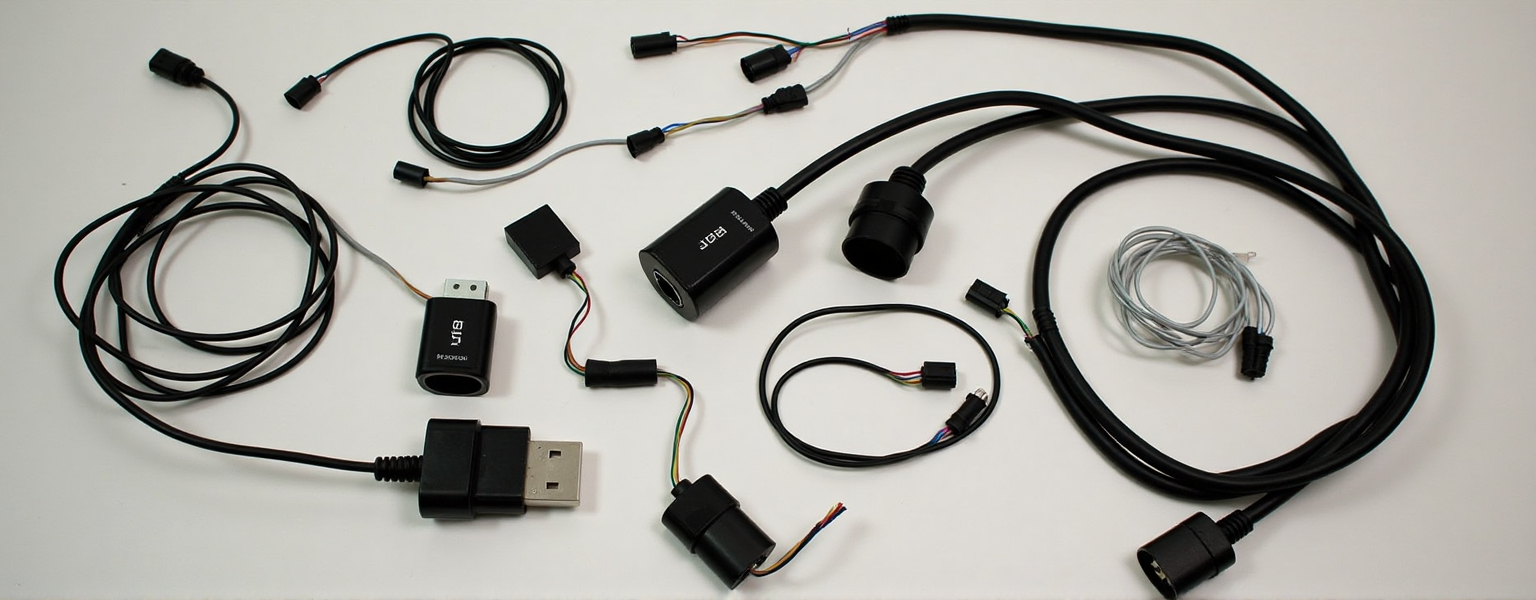

▷ Wire Harness

A wire harness is an integrated assembly of multiple individual wires or cables bundled together (using tape, conduits, etc.) and equipped with connectors, terminals, or other interfaces. It is designed for organized and directional connections within complex systems.

Key Features:

- Multi-wire integration: Wires arranged in specific paths, often with branches;

- Additional components: Includes connectors (e.g., JST, Molex), fuses, and relays;

- Customized design: Tailored to fit spatial constraints and electrical requirements of specific devices (e.g., automotive, industrial robots).

▷ Cable

A cable is a unified structure containing one or multiple insulated conductors (e.g., copper cores, optical fibers) enclosed within a single protective jacket. It is primarily used for power transmission, signal transfer, or data communication over long distances.

Key Features:

- Unified jacket: Outer protective layer (e.g., PVC, rubber) provides waterproofing, abrasion resistance, or high-temperature tolerance;

- Standardized specifications: Classified by conductor count (single-core/multi-core) and voltage rating (e.g., 300V/600V);

- Specialized functions: Optimized for specific purposes (e.g., YJV power cables, Cat6 Ethernet cables).

▷ Core Differences Summary

| Aspect | Wire Harness | Cable |

|---|---|---|

| Structure | Multiple wires + connectors + custom protection | Single/multi-core conductors + unified jacket |

| Primary Function | Integration and management of complex internal circuits | Efficient power/signal transmission |

| Typical Use | Automotive wiring, industrial control panels | Building power supply, telecom base stations |

| Flexibility | High (custom branches, lengths, interfaces) | Low (fixed specifications, cut to length) |

▷ In Summary

A wire harness is a “systematic connectivity solution” focused on integration and customization, while a cable is a “functional transmission medium” emphasizing standardization and protection.

▶ Category Comparison

▷ Structure and Composition

| Comparative dimension | Wire Harness | Cable |

|---|---|---|

| Structure | Multiple wires + connectors + protective materials | Single/multi-core conductors + unified jacket |

| Functions | Integrate circuits for multi-node connections | Specialized long-distance transmission |

| Production | Manual assembly + customization, high cost | Mechanized + standardized, low cost |

| Installation | Predefined paths + localized repair | Direct laying + full replacement |

| Vibration resistance | Excellent (secured branches) | Moderate (vulnerable over spans) |

| Anti-interference | Shielding-dependent | High (inherent design) |

| Environmental adaptability | Fits tight spaces | Fixed outdoor/underground |

| Application scenarios | Automotive, robotics | Power grids, telecom |

▷ Key Takeaways

- Wire Harness = Customized for complex systems (flexible, costly);

- Cable = Efficient single-function transmission (low cost, standardized).

▶ Detailed Differences

Structural Design

▷ Wire Harness

- Multi-wire integration: Multiple independent wires arranged in specific paths, often with branches (e.g., a trunk splitting into sub-lines).

- Additional components: Includes connectors (e.g., waterproof plugs, terminals), fuses, relays, and even sensors.

- Protection methods: Outer layers wrapped with tape, conduits, or braided sleeves; metal shielding added in critical areas.

▷ Cable

- Unified structure: Conductors (single or multi-core) enclosed in a single jacket, with no branches.

- Jacket materials: Selected based on application (e.g., high-temperature silicone, flame-retardant PVC); may include multiple layers (e.g., insulation + armor).

- Standardized design: Produced to international standards (e.g., UL, IEC), with uniform size, color, and labeling.

Functional Performance

▷ Wire Harness

- Anti-interference: Relies on localized shielding (e.g., foil-wrapped branches); overall anti-interference capability is weaker than specialized cables.

- Mechanical adaptability: Flexible and bendable to fit complex spaces; strong resistance to vibration.

- Transmission types: Supports hybrid transmission of power, signals, and data (e.g., automotive CAN bus).

▷ Cable

- Transmission efficiency: Optimized for specific functions (e.g., low-loss fiber optics, high-frequency stability of coaxial cables).

- Protection rating: Jackets provide features like IP67 waterproofing and oil resistance for harsh environments.

- Long-distance stability: Reduced signal attenuation through conductor materials (e.g., oxygen-free copper) and structural designs (e.g., twisted pairs).

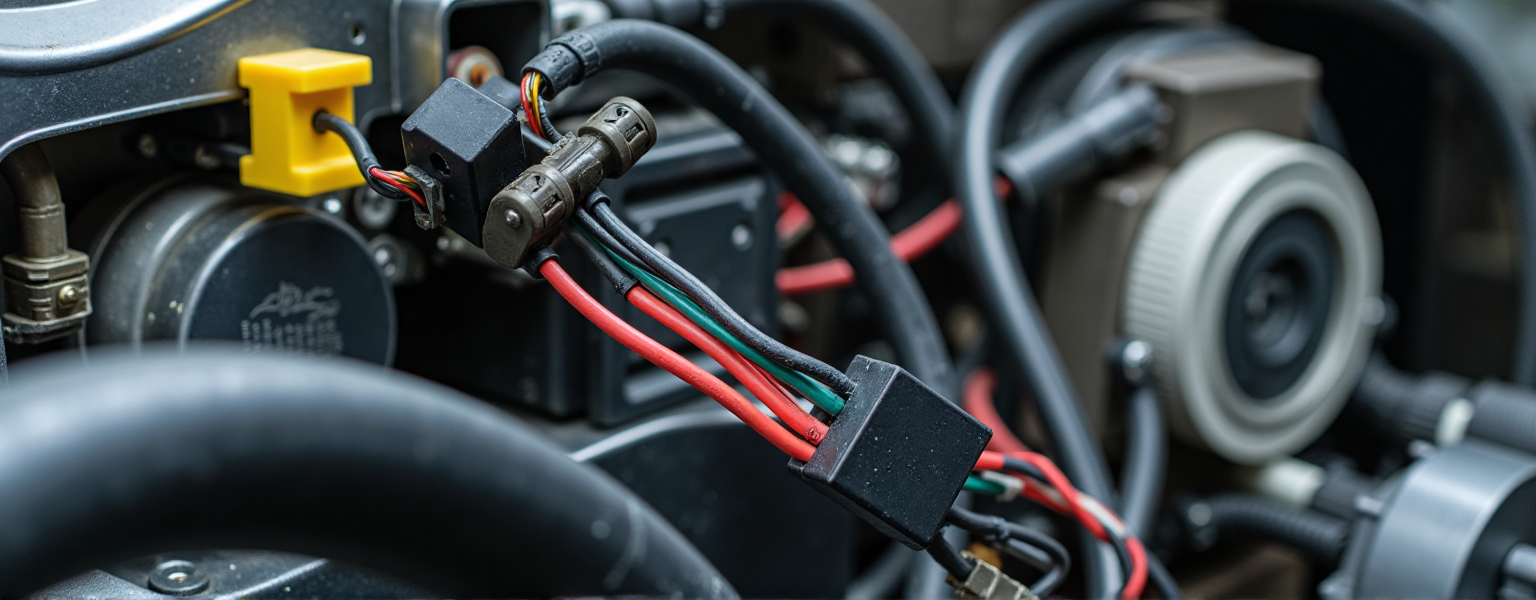

Application Scenarios

▷ Wire Harness

- Automotive: Connects engine control units (ECUs), lights, and sensors in high-temperature, high-vibration environments.

- Industrial equipment: Wiring for robot joints or interconnecting modules in CNC machines.

- Consumer electronics: Integrated circuits between laptop motherboards, screens, and keyboards.

▷ Cable

- Power transmission: Building power distribution (e.g., YJV cables), DC cables for solar farms.

- Communication networks: Fiber optic backbone networks, RF coaxial cables for 5G base stations.

- Special environments: Flame-retardant mining cables, submarine cables (corrosion and pressure resistant).

Cost and Production

▷ Wire Harness

- Design cost: Requires custom 3D routing diagrams and connector matching, with long development cycles.

- Production cost: High labor input (e.g., terminal crimping, tape wrapping); small-batch production increases costs.

- Inventory management: Requires stocking multiple connector and wire types due to customization.

▷ Cable

- Design cost: Standardized designs eliminate custom development; only selection is needed.

- Production cost: Mechanized jacket extrusion and bulk production achieve economies of scale.

- Inventory management: High versatility; stock standard lengths (e.g., 100m rolls).

Maintenance and Troubleshooting

▷ Wire Harness

- Localized repair: Individual wires or connectors can be replaced if damaged.

- Common issues: Poor contact (oxidized terminals), wear at branch points.

- Troubleshooting: Requires multimeters or harness testers for segment-by-segment checks.

▷ Cable

- Full replacement: Entire sections must be replaced if the jacket is damaged or conductors short-circuited.

- Common issues: Jacket degradation, physical damage (e.g., excavation cuts).

- Troubleshooting: Cable fault locators can quickly identify break points.

▷ In Summary

Wire Harness: Irreplaceable in complex system integration, but incurs additional costs for customization.

Cable: The cornerstone of efficient transmission, ideal for standardized, large-scale applications.

▶ How to Choose?

When to Choose a Wire Harness

- Complex internal connections:

- Devices require connections between multiple components (e.g., automotive ECUs, sensors, actuators) with intricate routing.

- Example: Automotive dashboard harness integrating power, signal, and data lines.

- Space constraints and flexibility:

- Need to fit tight spaces or follow curved paths (e.g., robot joints, appliance internals).

- Example: Drone wiring绕过 motors and camera modules.

- Modularity and maintenance:

- Require quick plug-and-play replacements (e.g., pre-assembled harnesses in industrial equipment).

- Example: Server rack detachable power harnesses.

- Vibration and interference resistance:

- Secure wiring in high-vibration environments (e.g., aerospace systems).

- Example: Aircraft engine harnesses with metal braided shielding.

When to Choose a Cable

- Single-function transmission:

- Only need to transmit power, signals, or data (e.g., household sockets, fiber optics).

- Example: BV wires for 220V AC power in buildings.

- Long-distance standardized deployment:

- Cross-area laying without frequent adjustments (e.g., underground power conduits, telecom base stations).

- Example: YJV high-voltage cables in urban underground grids.

- Harsh environment protection:

- Require waterproofing, heat resistance, or corrosion resistance (e.g., outdoor lighting, chemical plants).

- Example: Double-armored waterproof cables for deep-sea exploration.

- Cost-sensitive projects:

- Limited budgets without customization needs (e.g., home renovation, temporary power supply).

- Example: Rubber-jacketed cables for temporary stage lighting.

Key Decision Factors

| Factor | Prioritize Wire Harness | Prioritize Cable |

|---|---|---|

| Connection Complexity | Multi-node, hybrid signal transmission | Single-function transmission |

| Installation Environment | Tight spaces, high-vibration environments | Outdoor, underground, fixed long-distance |

| Customization Needs | Requires layout-specific design (length, branches, interfaces) | Standard specifications suffice |

| Budget & Timeline | Higher cost and longer lead times acceptable | Low cost and fast delivery preferred |

| Maintenance Ease | Supports localized repairs | Full replacement typical |

Practical Case Recommendations

- Case 1: EV Charging System

- Choose Harness: Connections between high-voltage batteries, motors, and charging ports require vibration resistance, EMI shielding, and custom branches.

- Avoid Cable: Standard cables cannot fit vehicle layouts and complicate maintenance.

- Case 2: Data Center Networking

- Choose Cable: Cat6A Ethernet or fiber optics for high-speed data between server rooms, with efficient standardized deployment.

- Avoid Harness: No complex branches needed; harnesses add unnecessary cost and complexity.

▷ In Summary

Wire Harness: Acts as the “neural network” for complex systems, excelling in integration and flexibility.

Cable: Serves as the “highway for transmission”, prioritizing efficiency and cost control.

Decision Formula: Complexity + Environmental Constraints + Budget → Choose Harness or Cable.

▶ Summary

Core Comparison Table

| Dimension | Wire Harness | Cable |

|---|---|---|

| Definition | Customized multi-wire assembly with connectors | Standardized transmission medium with jacket |

| Key Strength | Adapts to complex layouts; modular maintenance | Efficient transmission; long-distance stability |

| Typical Use | Automotive circuits, industrial robots | Building power grids, telecom networks |

| Cost Profile | High (custom design + manual labor) | Low (standardized mass production) |

| Maintenance | Localized repairs (single wire/connector) | Full replacement (damaged jacket) |

▷ Summary Statement

- Wire Harness acts as the “blood vessels and neural network” of complex systems, solving multi-node connections through integrated design, ideal for space-constrained, high-vibration, or maintenance-intensive scenarios.

- Cable serves as the “backbone channel” for functional transmission, prioritizing standardization and efficiency, suitable for long-distance, single-function, and cost-sensitive projects.

- Decision Priorities:

- Choose Harness: Complexity > Customization > Vibration/EMI Resistance;

- Choose Cable: Transmission Efficiency > Cost Control > Environmental Protection.

▷ Final Decision Formula

Application Complexity × Budget Constraints ÷ Maintenance Needs → Harness or Cable

Examples:

- Automotive assembly line (high complexity + medium budget + high maintenance) → Harness

- Home electrical renovation (low complexity + low budget + low maintenance) → Cable

Final Reminder:

- Early-stage planning: Define requirements for harnesses or cables during design to avoid rework.

- Expert collaboration: Consult engineers and suppliers for complex projects to optimize solutions.

- Pre-deployment testing: Validate electrical performance and mechanical durability before installation.

No comments to show.

Leave a Comment