Wiring harnesses are critical components in electronic devices, automotive systems, industrial machinery, and other fields. Their quality, compatibility, and reliability directly impact the performance and safety of the overall system. However, with the wide variety of wiring harness specifications available on the market, choosing the wrong type can lead to connection failures, signal interference, or even equipment damage.

Therefore, before purchasing wiring harnesses, it is essential to clarify key factors such as technical requirements, material standards, and supplier qualifications to ensure the selected product meets the actual application needs.

Table of contents

I. Technical Specifications and Compatibility

▶ Do the electrical parameters meet the requirements?

The electrical performance of wiring harnesses directly affects their safety and stability. Confirm the following:

▪ Voltage rating: Does it match the operating voltage of the equipment (e.g., 12V, 24V, high voltage 480V)?

▪ Current-carrying capacity: Can the wire cross-sectional area (e.g., 0.5mm², 1.0mm²) handle the maximum current without overheating?

▪ Impedance and signal integrity (for high-frequency or data cables): Is a low-impedance design required to minimize signal loss?

▪ Insulation rating: Does it meet industry safety standards (e.g., UL 1571, VDE) for withstand voltage testing?

Example: Automotive wiring harnesses typically require high-temperature resistance (above 105°C), while industrial equipment may need EMI shielding.

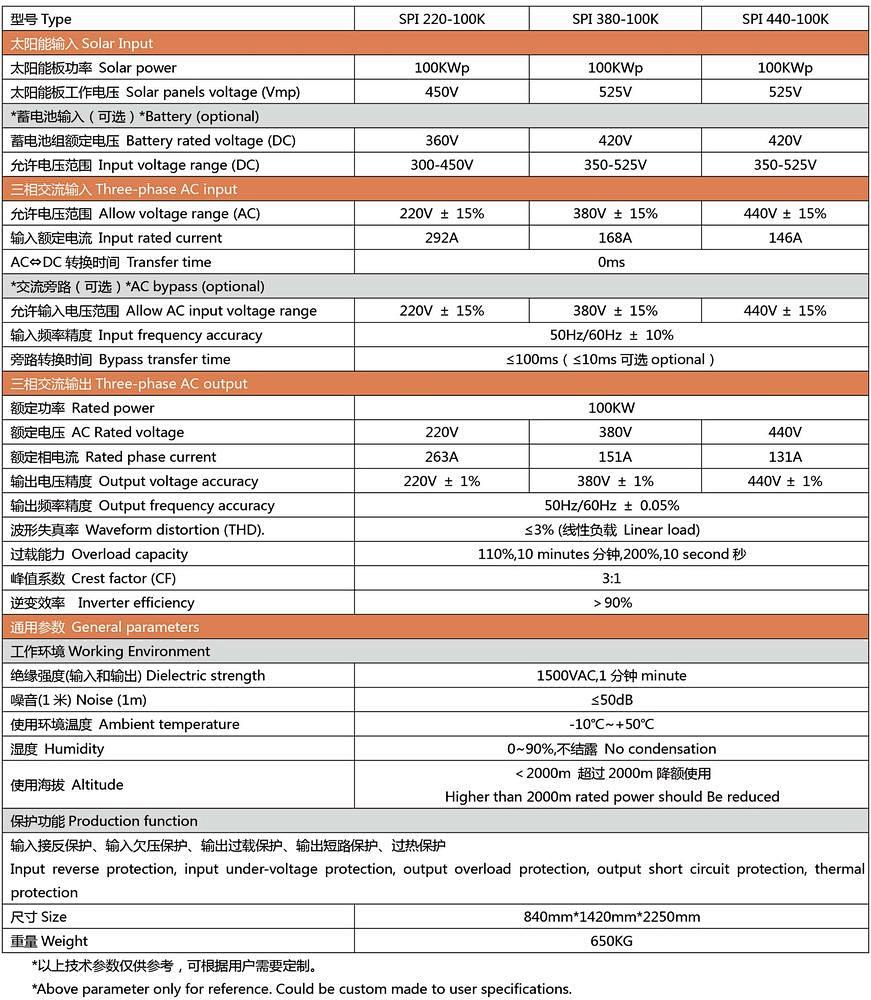

▲ A diagram of the electrical parameters ▲

▶ Are the connector types compatible?

The connectors determine whether the harness can properly interface with the equipment. Confirm:

▪ Interface type: Standard brands (e.g., Molex, JST, Deutsch, AMP) or custom plugs?

▪ Terminal specifications: Pin count (e.g., 2Pin, 4Pin), pitch (e.g., 2.54mm, 5.08mm), and compatibility.

▪ Special requirements: Waterproof (IP67), vibration-resistant (e.g., automotive-grade), or quick-disconnect designs?

Example: Medical equipment harnesses may require liquid-proof sealed connectors, while robotic cables may need gold-plated terminals for high mating cycles.

▶▶▶ Tip: Provide physical photos or model numbers of the equipment interfaces to suppliers to reduce matching errors.

▷ Summary

▪Incorrect electrical parameters → May cause short circuits, overheating, or signal loss.

▪Connector mismatch → Installation failure, requiring custom rework and increased costs/time.

II. Materials and Durability

The materials and durability of wiring harnesses directly affect their service life and performance, especially in harsh environments (e.g., high temperature, humidity, vibration). Therefore, the following key questions must be confirmed before purchasing:

▶ What materials are used for the wires and sheathing?

▪ Conductor material: Typically copper (bare copper, tin-plated copper, or silver-plated copper), with different platings affecting conductivity and oxidation resistance.

▪ Insulation material: Common options include PVC (low cost, flexible), silicone (high-temperature resistant), TPE (eco-friendly, oil-resistant), etc., selected based on the application environment.

▪ Outer jacket: Does it have wear-resistant, flame-retardant, or UV-resistant properties? For example, automotive harnesses may require oil- and high-temperature-resistant materials (e.g., XLPE).

▪ Shielding design: Is aluminum foil or braided shielding required to reduce electromagnetic interference (EMI)?

▶ How adaptable is it to environmental conditions?

▪ Temperature range: Can the harness operate normally in extreme temperatures (e.g., -40°C to 125°C)?

▪ Water and dust resistance: Is an IP67 or higher protection rating needed (e.g., for automotive or outdoor equipment)?

▪ Chemical resistance: Will it be exposed to oils, acids, alkalis, or other corrosive substances?

▪ Mechanical strength: Is tensile or flex resistance required (e.g., for robotic or mobile equipment harnesses)?

▷ Example applications:

▪Automotive harnesses → Require high-temperature, oil, and vibration resistance (e.g., silicone jacket + tin-plated copper).

▪Industrial equipment → May need shielding + wear-resistant jackets (e.g., TPE).

▪Medical devices → Must comply with biocompatibility standards (e.g., halogen-free materials).

▷ Key recommendations:

▪Request material certifications from suppliers (e.g., UL, VDE, ISO).

▪Conduct sample testing under extreme conditions (e.g., thermal cycling, salt spray tests).

▶▶▶ By clarifying these issues, you can ensure the harness maintains stability and safety during long-term use, avoiding failure risks caused by material degradation.

III. Customization and Dimensional Requirements

The degree of customization for wiring harnesses directly affects their applicability and installation convenience. If the dimensions, layout, or special requirements don’t match the actual application, it may lead to installation difficulties, performance degradation, or even safety hazards. Therefore, the following key questions must be clarified before procurement:

▶ Is customized length or routing required?

▪ Harness length: Standard-length harnesses may not meet specific equipment installation needs. Excessive length causes redundancy, while insufficient length may prevent connections. Precisely measure required lengths based on equipment layout and confirm if suppliers support custom cutting.

▪ Branch quantity and layout: Complex equipment may require multi-branch harnesses (e.g., mainline + multiple branches). Clarify branch point locations, lengths, and connection methods (e.g., T-junctions, star distribution).

▪ Color coding and labeling: For harnesses with multiple wires, color differentiation or labeling significantly reduces installation and maintenance errors, especially in automotive or industrial control applications.

▶ Are special protective or pre-assembled designs needed?

▪ Sleeving and protective layers: Additional protections like corrugated tubes, braided sleeves, or heat-shrink tubing may be required for high-temperature, high-friction, or harsh environments.

▪ Pre-assembled terminals/connectors: Some applications (e.g., automotive harnesses) require factory-preassembled connectors. Confirm supplier capabilities and interface compatibility.

▪ Bend radius and fixation methods: For frequent bending or confined-space routing, specify minimum bend radii and consider accessories like cable ties or clips.

▷▷ Why is this critical?

▪Avoid installation issues: Incorrect custom dimensions may prevent installation or require modifications, increasing costs and time.

▪Enhance reliability: Proper protection and routing reduce risks of wear, short circuits, and failures.

▪Optimize performance: Appropriate lengths and layouts minimize signal interference (e.g., in high-frequency applications) and improve system stability.

▶▶▶ Recommendation: Provide suppliers with detailed equipment layout diagrams or 3D models to ensure custom harnesses fully match requirements. Request samples for testing and validation.

IV. Supplier and Certification

Choosing the right wiring harness supplier is not only about product quality but also affects long-term cooperation stability and after-sales support. Before procurement, be sure to verify the supplier’s qualifications and product certifications to avoid project delays caused by quality or compliance issues.

▶ Does the supplier have relevant industry experience?

▪ Inquire whether the supplier has provided wiring harness products for similar industries (e.g., automotive, medical, industrial automation, etc.).

▪ Request successful case studies or customer references to evaluate their technical capabilities and reliability.

▶ Do the products comply with industry certification standards?

▪ Environmental certifications: Such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), etc., to ensure compliance with environmental regulations.

▪ Safety certifications: Such as UL (USA), CE (EU), IPC (electronics industry standards), etc., to guarantee electrical safety and reliability.

▪ Industry-specific certifications: Such as IATF 16949 for automotive industry, ISO 13485 for medical industry, etc. (depending on application field).

▶ Does the supplier provide quality assurance and after-sales support?

▪ Confirm whether the supplier offers a warranty period, such as 12 months or longer product guarantee.

▪ Understand after-sales policies, including return/refund procedures or technical support services in case of quality issues.

▶ What about the supplier’s production capacity and supply chain stability?

▪ Ask about the supplier’s production capacity to ensure they can meet bulk order requirements and avoid delivery delays due to insufficient capacity.

▪ Evaluate their supply chain management capabilities to ensure stable raw material sources and avoid delivery issues caused by supply chain problems.

▷ Summary

Choosing qualified suppliers with proper certifications and industry experience can significantly reduce procurement risks and ensure wiring harness quality and long-term reliability.

V. Cost and Delivery

When purchasing wiring harnesses, in addition to technical specifications and quality, cost and delivery timelines are equally critical. Poor budget control or delivery delays may impact the entire project schedule. Therefore, be sure to clarify the following two key questions before purchasing:

▶ Pricing and Minimum Order Quantity (MOQ)?

▼ Is small quantity purchasing supported?

▪ Some suppliers only accept large volume orders, while startups or small projects may require small quantity purchases. Confirm whether the supplier’s MOQ matches your needs.

▼ How does volume pricing work?

▪ Unit prices may vary at different order quantities (e.g., significant difference between 1,000pcs and 10,000pcs). Understanding the pricing structure helps optimize procurement costs.

▼ Are there hidden costs?

▪ Additional fees may include mold costs, testing fees, shipping charges or custom packaging fees. Be sure to confirm these upfront to avoid budget overruns.

▶ Delivery Lead Time and After-Sales Service?

▼ What are production lead times for standard and custom products?

▪ Standard harnesses may be readily available for quick delivery, while custom harnesses may require longer production times (e.g., 2-4 weeks or more) that need advance planning.

▼ Is expedited production available?

▪ For urgent projects, inquire whether the supplier offers expedited services and how additional charges are calculated.

▼ Quality warranty and after-sales policy?

▪ Confirm if a warranty period is provided (e.g., 12 months) and problem resolution procedures (returns, repairs or replacements).

▷ Summary

CFor wiring harness procurement, cost and delivery directly impact project budgets and schedules. Be sure to confirm pricing structures, MOQs, delivery timelines and after-sales policies in advance to ensure smooth procurement and avoid unnecessary delays or additional expenses.

☑ Seller Summary: Key Points for Purchasing Wiring Harnesses

As a wiring harness supplier, we understand the importance of selecting the right product for your project. To ensure you receive a cost-effective and reliable solution, we recommend focusing on the following key aspects during procurement:

▪ Technical Compatibility: Clarify electrical and mechanical parameters such as voltage, current, and connector types to avoid compatibility issues. We offer sample testing to ensure the harness perfectly matches your equipment.

▪ Material and Durability: Choose wire materials, sheathing, and protection levels based on the application environment (e.g., high temperature, vibration, chemical exposure). We provide UL, VDE, and other certified materials to guarantee long-term stability.

▪ Customization Requirements: Specify precise length, branch layout, or special protection needs. We support personalized designs and can optimize solutions using 3D models.

▪ Certifications and Delivery: With industry certifications (e.g., IATF 16949, RoHS) and a mature supply chain, we flexibly accommodate small or large orders, offering transparent pricing and on-time delivery.

We are committed to providing technically compliant, high-quality, and cost-optimized wiring harness solutions. Feel free to reach out with your requirements—we will respond promptly and offer professional support!

No comments to show.

Leave a Comment