Wire Gauge / Contact / Housing Matching Relationship Comparison Table

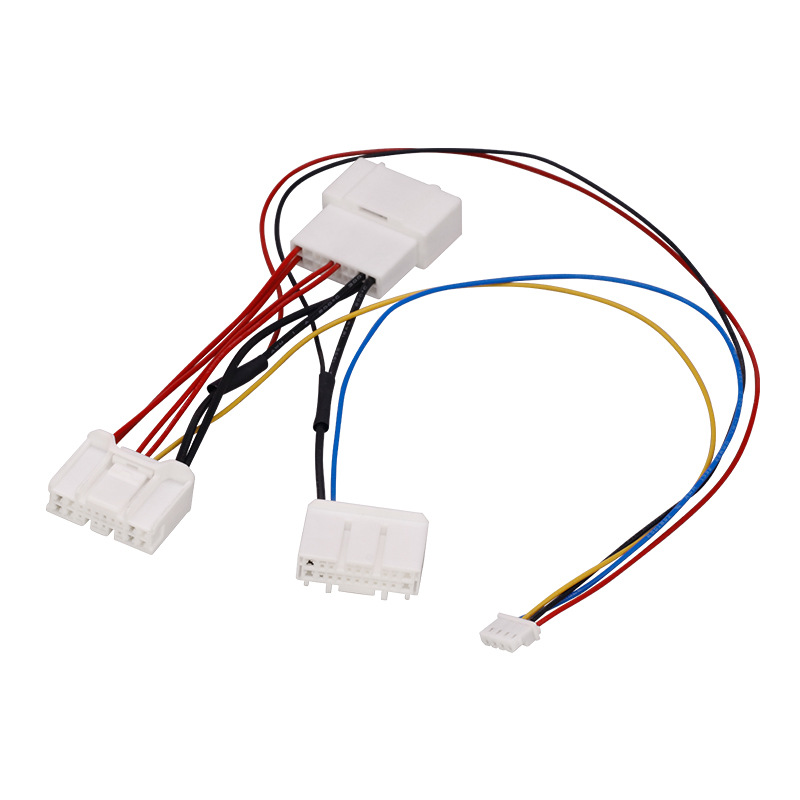

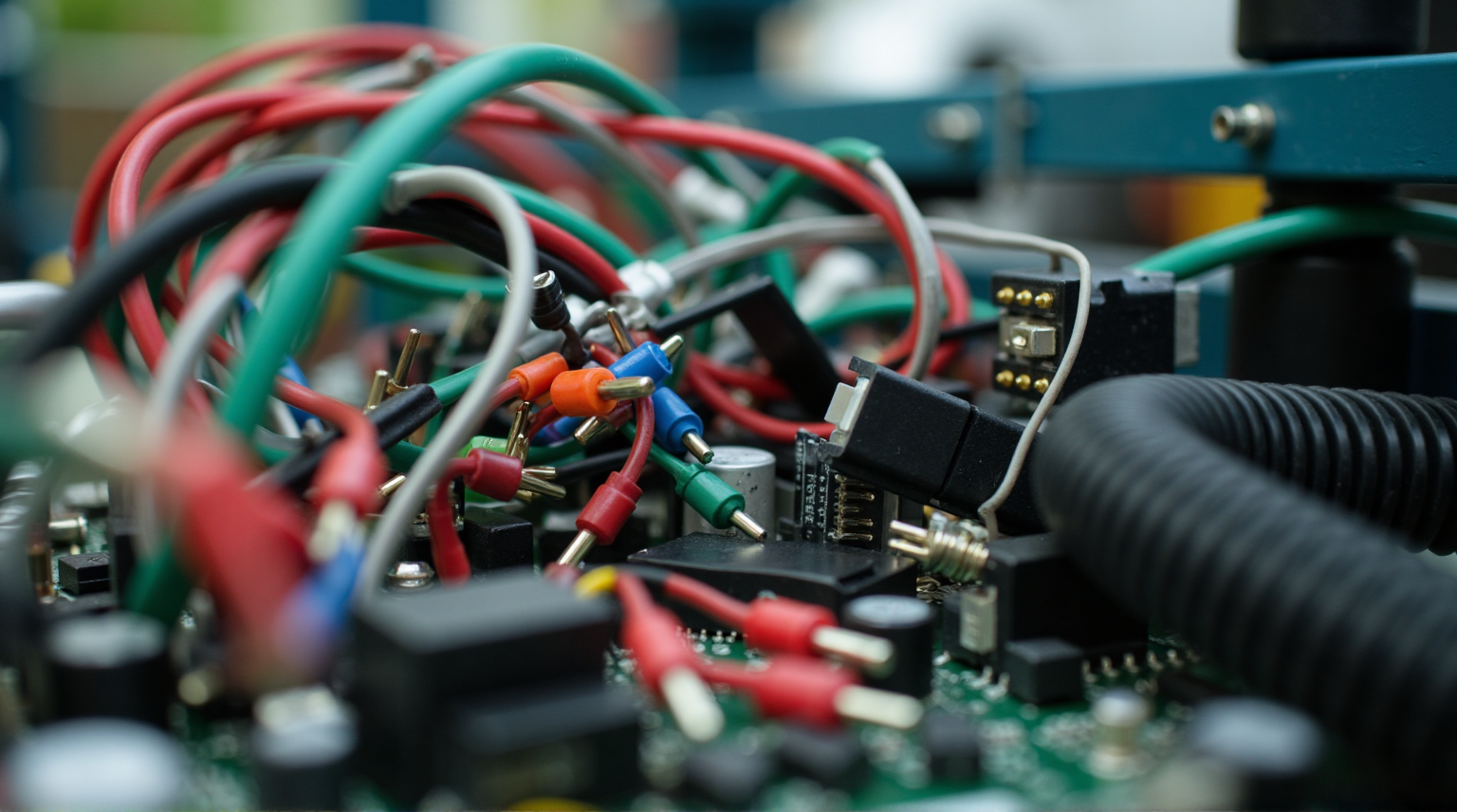

The matching relationship between wire gauge, contact (terminal), and housing (connector) is a core element in electronic connector design and wire harness assembly. These three components must precisely coordinate to ensure the reliability, mechanical strength, signal integrity, and assemblability of the electrical connection.

▶ Core Principles:

• Wire Gauge Determines Contact: The inner diameter of the contact’s wire barrel must match the outer diameter of the conductor (after stripping the insulation) to ensure the reliability and conductivity of the crimp.

• Contact Determines Housing: The shape and size of the contact (especially the locking structure, barbs position) must fully match the cavity design inside the housing, ensuring the contact can be correctly inserted, locked (retained), and polarized.

• Housing Determines Application: The housing’s shape, locking mechanism, sealing properties, and material grade (e.g., temperature resistance, flame retardancy) determine its suitable environment and end product (e.g., automotive, consumer electronics, industrial equipment).

• Standards & Specifications: Most connector systems adhere to industry standards (like Molex, TE Connectivity, JST, Amphenol, which have their own series) or international standards (e.g., USCAR, JASO, DIN).

※ You MUST refer to the specific connector series’ technical datasheet for final confirmation!

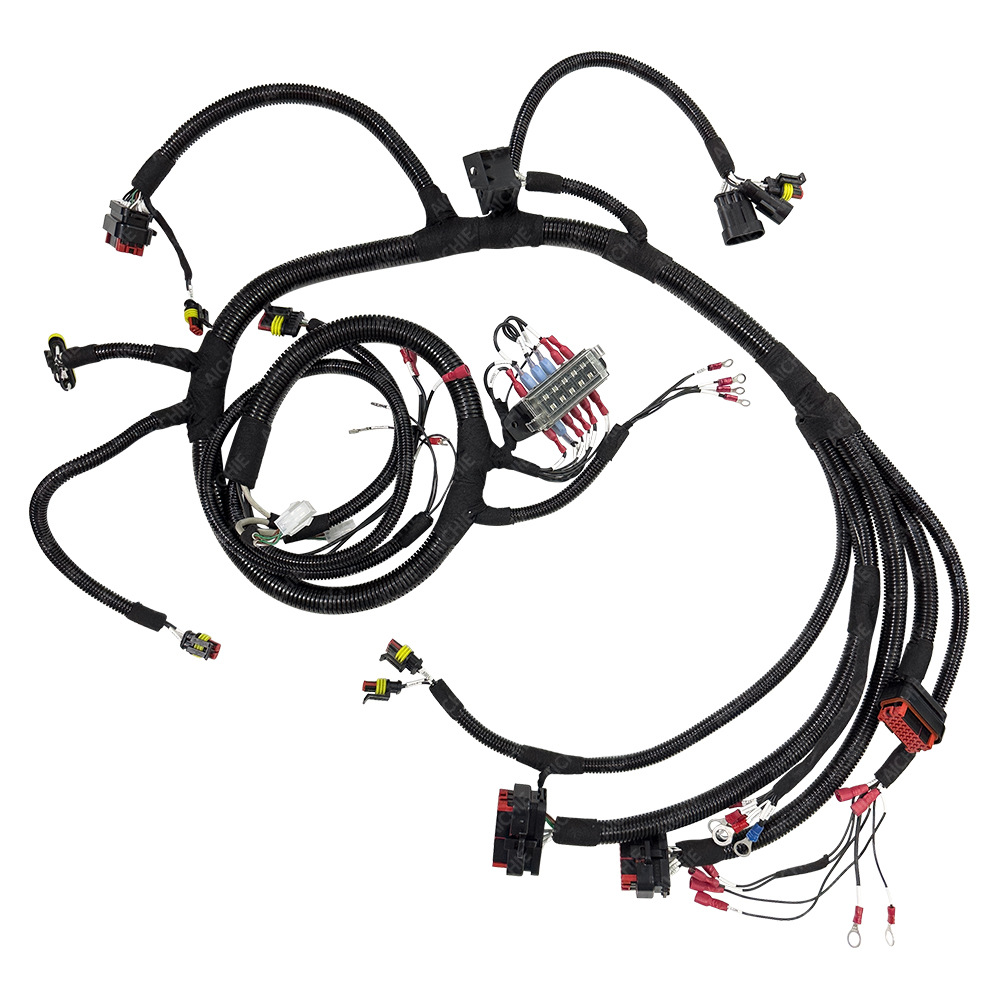

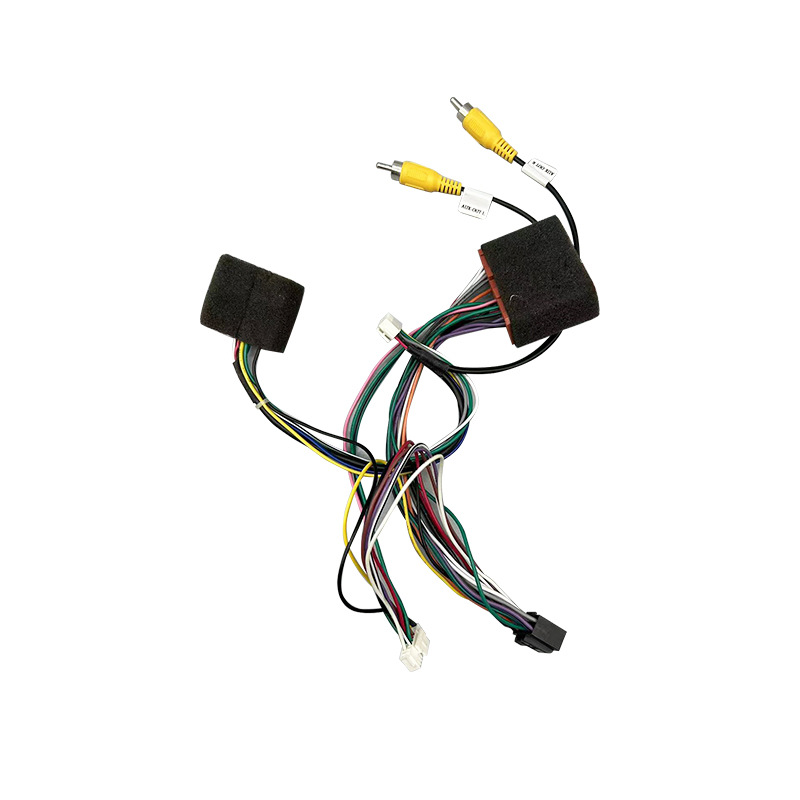

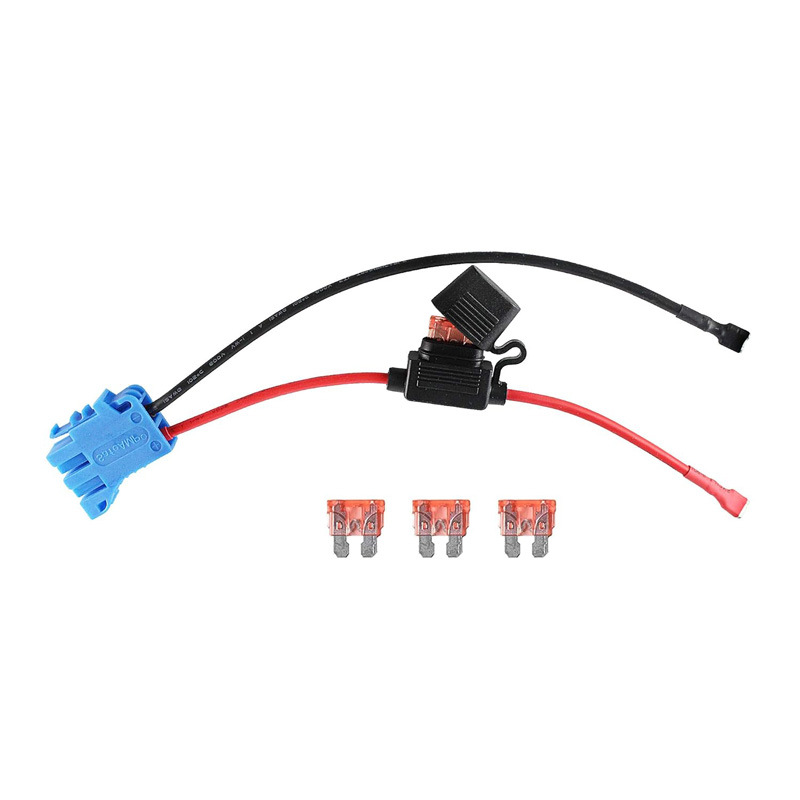

▶ Automotive Electronics Applications (High Reliability, Vibration Resistance, Environmental Endurance)

| Wire Gauge (AWG/mm²) | Typical Contact Type/Series | Typical Housing Series/Characteristics | Representative Applications/Notes |

|---|---|---|---|

| 20-24 AWG | Mini/Micro Contacts | Housing Series: JST SHL, JST GH, Molex MX123, TE MQS, Delphi GT 150 | Apps: Body Control Module (BCM), sensors, switches, lighting (LED), infotainment low-current signals. Note: Miniaturized design, pay attention to insertion/removal force and retention. |

| (0.5-0.25 mm²) | (e.g., JST SH, Molex MX123) | Chars: Miniaturized, with CPA (Connector Position Assurance)/TPA (Terminal Position Assurance), often sealed (Sealed versions), dual lock (contact lock + housing latch) | |

| 16-20 AWG | USCAR/0.64 Series Contacts | Housing Series: TE MCON 0.64, Delphi GT 150 (partial), Molex MX150 | Apps: Mainstream automotive wire harnesses: ECU connections, sensors, actuators, medium-low power loads (e.g., small motors, relay coils). Note: One of the most widely used automotive standards. |

| (1.0-0.5 mm²) | (Standard Size) | Chars: Compliant with USCAR standard, with CPA/TPA, often sealed, multiple keying positions for polarization, dual lock | |

| 14-18 AWG | USCAR/1.5 Series Contacts | Housing Series: TE MCON 1.5, Delphi GT 280, Molex MX150 (large cavity) | Apps: Higher current loads: headlights, fan motors, fuel pumps, ABS pump power, partial battery connections. Note: Stronger load capacity. |

| (2.5-1.0 mm²) | Chars: Compliant with USCAR standard, with CPA/TPA, often sealed, dual lock | ||

| 10-14 AWG | USCAR/2.8 Series Contacts | Housing Series: TE MCON 2.8, Delphi GT 480, Molex MX150 (larger cavity) | Apps: High-current main power: starter, alternator, battery positive main harness, high-power heaters. Note: Ensure crimp quality and contact material. |

| (6.0-2.5 mm²) | Chars: Compliant with USCAR standard, with CPA/TPA, often sealed, dual lock | ||

| 8-12 AWG | Power Contacts (Electrical Parts) | Housing Series: Dedicated high-current connectors (e.g., TE HVP800, Molex MX-BLC, Amphenol RADSOK) or PCB terminal blocks/bolt-on connections | Apps: New energy vehicle (NEV) high-voltage auxiliary systems (12V/48V), traditional vehicle high-power appliances (>30A). Note: May require special crimping tools or soldering. |

| (10-4 mm²) | (e.g., ring terminals, spade terminals, high-current crimp terminals) | Chars: Large size, high current-carrying capacity, may require auxiliary fixing (bolts), pay attention to temperature rise. | |

| HV Cables | HV Contacts | Housing Series: Dedicated high-voltage connectors (e.g., TE HVP800, HVA320, Amphenol Radsok, Rosenberger HVR) | Apps: NEV battery packs, motor controllers, on-board chargers (OBC), DC/DC converters, etc. (>60V). Note: Strictly follow HV safety norms, color coding (orange), interlock design, high-level sealing. |

| (Common 35-120 mm²) | (Special design, often RADSOK or blade contacts) | Chars: High voltage rating (e.g., 600V/1000V DC), high current capability, mandatory interlock, active/passive discharge design, high-level sealing/IP protection, touch protection design |

▶ Consumer Electronics/Computer/Networking Applications (Miniaturization, High Density, Low Cost)

| Wire Gauge (AWG/mm²) | Typical Contact Type/Series | Typical Housing Series/Characteristics | Representative Applications/Notes |

|---|---|---|---|

| 26-32 AWG | FFC/FPC Connector Contacts | Housing Series: Various FFC/FPC Receptacles (e.g., Hirose FH12, JST FH, TE FFC) | Apps: LCD flex cables, camera modules, short-distance board-to-board connections inside motherboards. Note: Not crimped, clamps Flexible Flat Cable (FFC)/Flexible Printed Circuit (FPC). |

| (Ultra-fine wire) | (Clamping type, non-crimp) | Chars: Ultra-thin, high density, ZIF/LIF (Zero/Low Insertion Force) flip-lock mechanism | |

| 24-30 AWG | Micro Contacts | Housing Series: JST ZH (1.5mm pitch), JST GH (1.25mm), Molex PicoBlade (1.25mm), Hirose DF13 | Apps: Board-to-wire connections inside small devices: phones, tablets, drones, small modules. Note: Extremely fine, requires very high precision for wire and crimping. |

| (0.08-0.2 mm²) | (e.g., JST ZH, Molex PicoBlade) | Chars: Ultra-fine pitch (1.25mm, 1.0mm), single/dual row, simple latch | |

| 22-28 AWG | Small Pitch Contacts | Housing Series: JST PH (2.0mm), JST XH (2.5mm), Molex KK (2.54mm/0.1″), TE AMPMODU (2.54mm) | Apps: Most widespread: motherboard power/signals, fans, sensors, development boards (Arduino/Raspberry Pi), toys. Note: 2.54mm is the most classic pitch. |

| (0.3-0.08 mm²) | (e.g., JST PH/XH, Molex KK) | Chars: Pitch 2.0mm-2.54mm, single/dual row, with contact lock (often requires special tool for extraction), low cost | |

| 20-24 AWG | Standard Pitch Contacts | Housing Series: Molex Mini-Fit Jr (3.0mm), Molex Mega-Fit (5.7mm), TE MTA-100 (2.54mm but larger) | Apps: Computer power supplies (ATX 24pin, EPS 8pin, PCIe), server power supplies, medium-power device power. Note: High current capability, pay attention to crimp and housing latch. |

| (0.5-0.25 mm²) | (e.g., Molex Mini-Fit) | Chars: Larger pitch (3.0mm, 4.2mm, 5.7mm), high pin count (up to 24+), with contact lock and housing latch, optional polarization key | |

| RJ45 | 8P8C Modular Plug (RJ45) Contacts | Housing Series: RJ45 Modular Plug | Apps: Ethernet network connections (Cat5e, Cat6, Cat6a). Note: Wiring standards (T568A/B), twisted pair maintenance, shielding treatment (if required). |

| (Common 23-24 AWG) | (8 independent blade contacts) | Chars: Standardized plastic housing and latch | |

| USB/HDMI | Dedicated Contacts | Housing Series: Standard USB Type-A/B/C, Micro-USB, HDMI Plug/Receptacle | Apps: Data transfer and charging. Note: Highly standardized, usually pre-made cables or modules are purchased. Internal contacts are precision stamped contacts. |

| (Stranded fine wire) | (Precision stamped contacts) | Chars: Compliant with USB-IF/HDMI specifications |

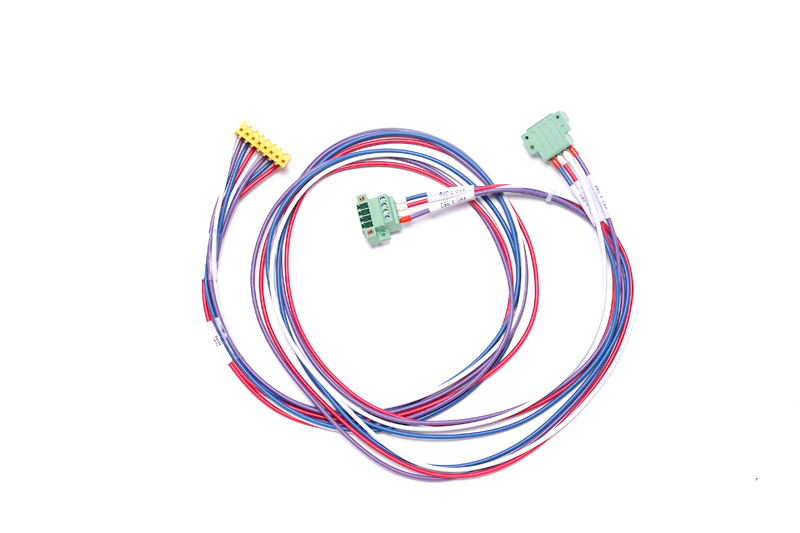

▶ Industrial Control/Automation Applications (Durability, Reliability, Diverse Environments)

| Wire Gauge (AWG/mm²) | Typical Contact Type/Series | Typical Housing Series/Characteristics | Representative Applications/Notes |

|---|---|---|---|

| 16-22 AWG | Eurostyle/PCB Terminals | Housing Series: Phoenix Contact PT (Plug-in), Weidmuller WDU, Wago 2000/2002 Series | Apps: PLC I/O modules, sensors, actuators, power distribution. Note: Spring-clamp (tool-less) or screw clamp, facilitates field wiring. |

| (1.5-0.3 mm²) | (Spring-clamp or screw clamp) | Chars: Modular, pluggable, straight/45°/90° wire exit, multi-color coding, high vibration resistance, optional marker strip | |

| 10-16 AWG | Heavy-Duty Rectangular Connector Contacts | Housing Series: TE DEUTSCH DT/DTP, Amphenol CPC, Molex ML-XT, Harting Han | Apps: Construction machinery, rail transit, energy equipment, equipment interconnection in harsh environments. Note: High protection rating (IP67/IP69K), oil/chemical resistance, vibration/shock resistance. |

| (6.0-1.5 mm²) | (Commonly crimped then inserted) | Chars: Metal or high-strength plastic shell, multi-point sealing (cable, housing interface), mechanical latch, anti-snagging design, modular design | |

| 8-14 AWG | Power/Large Current Terminals | Housing Series: Phoenix Contact COMBICON (High Current), Anderson Powerpole (No housing, mateable), High-Current Terminal Blocks | Apps: Motor drive main power, VFD input/output, high-power UPS/battery connections, DC power distribution. Note: Current carrying capacity, temperature rise, connection reliability. |

| (10-2.5 mm²) | (e.g., blade terminals, ring terminals, Anderson SB) | Chars: Large contact area, may require bolt auxiliary fixing, pay attention to insulation protection | |

| M8/M12 | M8/M12 Connector Contacts | Housing Series: Standard M8/M12 Circular Connectors (3-pin, 4-pin, 5-pin, 8-pin; A/B/C/D coded) | Apps: Industrial sensors (proximity switches, photoelectric sensors), fieldbus (Profinet, Ethernet/IP), small actuators. Note: Coding prevents mis-mating, protection rating (IP67/IP69K), threaded locking. |

| (Common 22-26 AWG) | (Crimp or spring-clamp) | Chars: Circular, metal/plastic housing, threaded locking, various pin counts/codings |

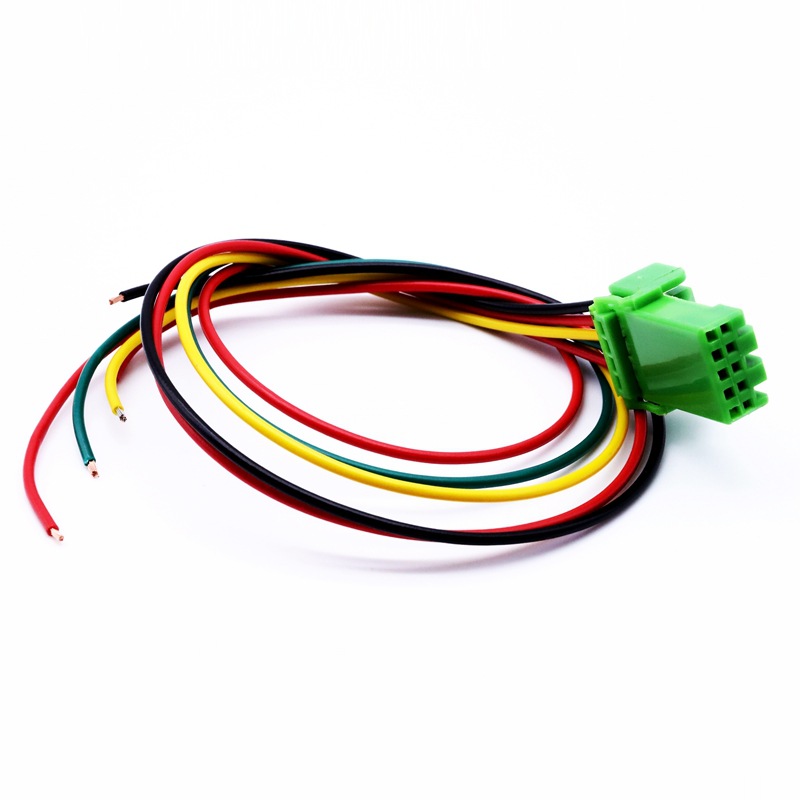

▶ Household Appliances/Lighting Applications (Cost-Sensitive, Basic Reliability)

| Wire Gauge (AWG/mm²) | Typical Contact Type/Series | Typical Housing Series/Characteristics | Representative Applications/Notes |

|---|---|---|---|

| 18-22 AWG | Faston/Spade Terminals | Housing Series: Usually connected directly to device tabs (e.g., on switches, thermostats) or PCB solder tabs, no separate housing. | Apps: Rice cookers, microwaves, electric fans, internal connections for switches, heating elements, small motors in lighting fixtures. Note: Low cost, easy installation, but poor retention and environmental sealing. |

| (0.75-0.3 mm²) | (e.g., 0.187″, 0.25″, 4.8mm, 6.3mm wide) | Chars: N/A | |

| 20-24 AWG | Small Board-to-Wire Connector Contacts | Housing Series: JST VH (3.96mm), JST XA (2.5mm), Molex KK (2.54mm) – Lower-cost versions | Apps: Connecting power, display boards, sensors to appliance control boards. Note: More cost-focused than consumer electronics, may have simplified latch designs. |

| (0.5-0.2 mm²) | (e.g., JST VH, Simplified Molex KK) | Chars: Common pitches 2.5mm, 3.96mm, simple latch or friction retention | |

| Lamp Socket Connection | Lamp Socket Specific Terminals | Housing Series: Standard Lamp Sockets (E26/E27, GU10, G4, G9, etc.) | Apps: Power connection for incandescent, CFL, LED bulbs. Note: Usually soldered or crimped to internal spring clips/contacts within the socket, not standard discrete contacts. |

| (Common 18-22 AWG) | (Solder tabs or spring contacts) | Chars: Standardized screw or bayonet base |

▶ Detailed Explanation of Key Matching Factors

Wire Gauge and Contact Matching:

• Crimping Range: Each contact model has a clearly defined applicable wire gauge range (AWG or mm²). If the wire is too small, the crimp won’t be tight, leading to high resistance and easy pull-out. If the wire is too large, the wire barrel may be stretched open or cracked, also resulting in unreliability.

• Conductor Type: Solid wire, stranded wire, plating (tin, silver) affect crimping results and tool selection.

• Insulation Diameter: For some contacts (e.g., with insulation support wings), the outer diameter of the insulation must also be considered to ensure it falls within the contact’s design range.

• Crimping Tool: Precisely matched crimping dies and tools must be used for the specific contact to ensure the crimp shape, height, and force comply with specifications. Crimp quality is the lifeline of connection reliability.

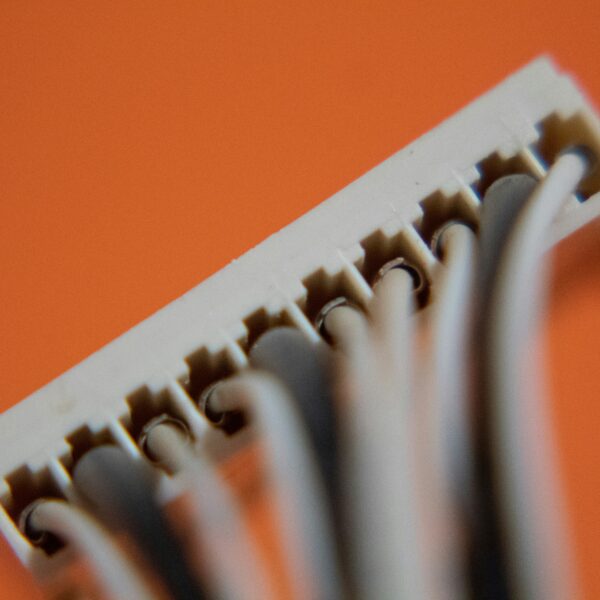

Contact and Housing Matching:

• Cavity Size: The contact must insert smoothly into the corresponding cavity of the housing. It cannot be too loose (wobbling) or too tight (difficult insertion or housing damage).

• Locking Structure: Contacts have locking barbs (Primary Lock), and the housing cavities have corresponding locking slots. Once fully inserted, the barbs should snap up and lock, providing retention force to prevent the contact from backing out. Some housings have a secondary locking mechanism (Secondary Lock/TPA), which is engaged after contact insertion, providing additional retention force and preventing barb failure.

• Polarization Keying: Housing cavities and contacts often have matching protrusions/recesses (Polarization Key), ensuring the contact can only be inserted in the correct orientation and position, preventing misinsertion.

• CPA (Connector Position Assurance): In applications like automotive, housings often have a CPA (Connector Position Assurance) clip or slider that is engaged after the connector halves are mated and locked, preventing accidental unmating of the connector.

Housing and Application Matching:

• Current/Voltage Rating: The housing’s insulating material and creepage/clearance distances determine its voltage rating. Cavity size and adjacent contact spacing affect current carrying capacity and heat dissipation.

• Environmental Requirements:

- Temperature: Materials must meet the operating temperature range (e.g., automotive: -40°C ~ 125°C+).

- Sealing: Applications requiring water resistance (e.g., automotive engine bay, outdoor equipment) need housings with seals (cable grommets, interface seals) achieving corresponding IP ratings (e.g., IP67, IP69K).

- Chemical Resistance: Environments exposed to oils, solvents, or cleaning agents require chemically resistant materials.

- Mechanical Strength: Resistance to vibration, shock, and mating/unmating cycles.

• Locking Mechanism: The locking method after connector mating (lever lock, push-pull lock, slider lock, screw lock) affects connection security and ease of operation.

• Mounting Style: Panel mount, wire/cable mount, PCB mount (through-hole, SMT).

▶ Summary and Selection Steps

• Define Requirements: Determine the application scenario (Automotive? Industrial? Consumer?), current/voltage, signal type, environmental conditions (temperature/humidity, vibration, sealing requirements), wire harness length, space constraints, cost targets.

• Determine Wire Gauge: Calculate based on current load or refer to standards to select the appropriate conductor cross-sectional area (AWG/mm²).

• Select Connector System:

- Based on the application field, refer to common industry standards or major manufacturer series (e.g., choose automotive-grade series from TE/JST/Molex for automotive).

- Within that series, find the applicable contact model based on the wire gauge. You MUST check the contact’s Datasheet to confirm the wire gauge range.

- Based on the contact model, select the matching housing model (pay attention to pin count, keying options, sealing options, locking type, etc.). You MUST check the housing’s Datasheet to confirm the compatible contact list and cavity layout.

• Confirm Accessories: Check if accessories like Seals/Seal Plugs, Terminal Position Assurance (TPA) components, Connector Position Assurance (CPA) components, Backshells, or Strain Reliefs are needed.

• Tools and Process: Select the correct crimping tools, contact insertion tools, and connector assembly/testing tools (e.g., insertion/removal force gauge, continuity tester). Establish and strictly adhere to precise crimping and assembly process specifications.

※ Remember: The comparison table provided in this document is a general guide. In practical applications, you MUST, MUST, MUST (say it three times!) consult the official, latest version of the technical datasheet and product drawings provided by the specific connector manufacturer you are using! Subtle differences between different manufacturers and series can lead to incompatibility. Precise matching is the only way to guarantee connection reliability.

Geen reacties om te tonen.

Laat een reactie achter