Understanding the Role of Insulation in Cable Performance

Cable insulation is the protective material surrounding the conductive core of a cable, and it plays a crucial role in ensuring the safe and efficient operation of electrical systems. It prevents electrical current leakage, safeguards against external environmental factors, and directly impacts the cable’s reliability and lifespan.

Table of contents

1. Introduction

1.1 Definition of Cable Insulation

Cable insulation refers to the material or layer that surrounds the conductive core of a cable. It serves to prevent electrical current from leaking out of the conductor and to protect the cable from external environmental factors.

1.2 Importance of Insulation

Proper insulation is crucial for the safe and efficient operation of electrical systems. It ensures that electrical energy is transmitted with minimal loss and that there is no risk of electrical shock or short circuits.

2. Types of Insulation Materials

2.1 Polyvinyl Chloride (PVC)

Characteristics:

▪Cost-Effective: PVC is relatively inexpensive, making it a popular choice for many applications.

▪Flame Retardant: It has good flame retardant properties, which is important for safety in case of fire.

▪Mechanical Strength: It offers sufficient mechanical strength to protect the cable from physical damage.

▪Chemical Resistance: PVC is resistant to many chemicals, which helps in protecting the cable from corrosion.

Characteristics:

PVC-insulated cables are widely used in building wiring, power distribution, and low-voltage applications.

2.2 Polyethylene (PE)

Characteristics:

▪High Insulation Resistance: PE has excellent insulation properties, which means it can effectively prevent electrical leakage.

▪Low Dielectric Loss: It results in minimal energy loss during electrical transmission.

▪Flexibility: PE is flexible, making it easy to install and route cables.

▪Water Resistance: It is resistant to moisture, which is beneficial for cables used in damp environments.

Applications:

PE-insulated cables are commonly used in high-frequency communication cables, coaxial cables, and underwater cables.

2.3 Cross-Linked Polyethylene (XLPE)

Characteristics:

▪High Temperature Resistance: XLPE can withstand higher temperatures compared to regular PE, which allows it to be used in high-current applications.

▪Improved Mechanical Properties: The cross-linking process enhances its mechanical strength and abrasion resistance.

▪Good Chemical Stability: It remains stable under various chemical conditions.

▪Excellent Insulation Performance: It maintains high insulation resistance even at elevated temperatures.

Applications:

XLPE-insulated cables are used in medium and high voltage power transmission cables, submarine cables, and underground cables.

2.4 Rubber Insulation

Characteristics:

▪Flexibility: Rubber is highly flexible, which is essential for cables that need to be bent frequently.

▪Low Temperature Resistance: It can operate at low temperatures without becoming brittle.

▪Water Resistance: Rubber provides good protection against moisture.

▪Chemical Resistance: It has resistance to certain chemicals, though not as extensive as PVC.

Applications:

Rubber-insulated cables are used in portable power cables, control cables, and cables for mobile equipment.

3. Functions of Insulation in Cable Performance

3.1 Electrical Insulation

▪Preventing Electrical Leakage: The primary function of insulation is to prevent electrical current from escaping the conductor, which ensures efficient transmission of electrical energy and prevents electrical hazards.

▪Maintaining Voltage Levels: Proper insulation helps to maintain the voltage levels within the cable, reducing the risk of voltage drops and ensuring stable electrical performance.

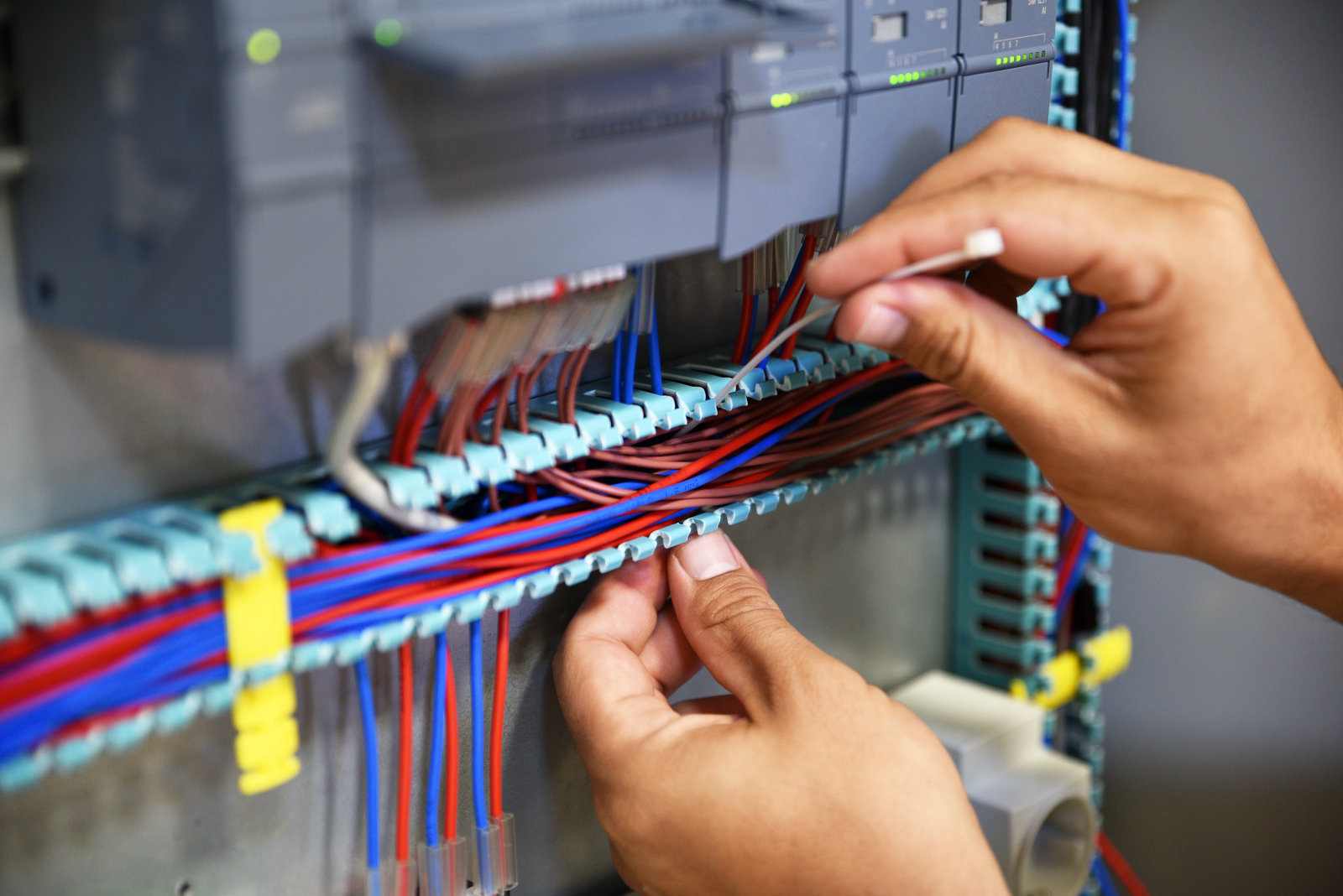

3.2 Mechanical Protection

▪Protecting Against Physical Damage: Insulation provides a protective layer around the conductor, shielding it from external forces such as abrasion, impact, and compression.

▪Enhancing Cable Durability: By protecting the conductor from physical damage, insulation increases the overall durability and lifespan of the cable.

3.3 Thermal Management

▪Reducing Heat Loss: Insulation can help to reduce heat loss from the conductor, which is particularly important in high-current applications where significant heat is generated.

▪Maintaining Temperature Stability: Proper insulation ensures that the temperature within the cable remains stable, preventing overheating and potential damage to the cable.

3.4 Environmental Protection

▪Protecting Against Moisture and Humidity: Insulation prevents moisture from penetrating the cable, which can cause electrical faults and corrosion.

▪Resisting Chemicals and Contaminants: Insulation materials can protect the cable from exposure to chemicals, oils, and other contaminants that may degrade the cable’s performance.

4. Factors Affecting Insulation Performance

4.1 Material Quality

▪Purity: High-purity insulation materials have fewer impurities, which can improve insulation performance and reduce the risk of electrical breakdown.

▪Manufacturing Process: The quality of the manufacturing process affects the consistency and reliability of the insulation material.

4.2 Thickness of Insulation

▪Adequate Thickness: Sufficient insulation thickness is necessary to provide effective electrical and mechanical protection.

▪Uniformity: The insulation should be uniformly applied to ensure consistent performance along the length of the cable.

4.3 Environmental Conditions

▪Temperature: Extreme temperatures can affect the performance of insulation materials, causing them to become brittle or lose their insulating properties.

▪Humidity: High humidity levels can lead to moisture absorption, which can degrade insulation performance.

▪Chemical Exposure: Exposure to chemicals can cause chemical degradation of the insulation material, reducing its effectiveness.

4.4 Installation and Handling

▪Proper Installation: Careful installation practices are necessary to avoid damaging the insulation during the installation process.

▪Handling: Proper handling during transportation and storage is important to prevent mechanical damage to the insulation.

5. Testing and Evaluation of Insulation

5.1 Electrical Tests

▪Insulation Resistance Test: This test measures the resistance of the insulation to electrical leakage. A high insulation resistance indicates good insulation performance.

▪Dielectric Withstand Test: This test checks the ability of the insulation to withstand high voltage without breakdown. It ensures that the insulation can handle the rated voltage of the cable.

5.2 Mechanical Tests

▪Tensile Strength Test: This test measures the ability of the insulation to withstand tensile forces without breaking.

▪Abrasion Resistance Test: This test evaluates the resistance of the insulation to wear and tear from friction.

5.3 Environmental Tests

▪Thermal Aging Test: This test simulates long-term exposure to high temperatures to evaluate the thermal stability of the insulation.

▪Moisture Resistance Test: This test checks the ability of the insulation to resist moisture absorption.

Summary

Insulation plays a vital role in the performance of cables. It provides electrical insulation, mechanical protection, thermal management, and environmental protection. The choice of insulation material and its quality directly affect the reliability and lifespan of the cable.

Nenhum comentário para mostrar.

Leave a Comment