Why choose us?

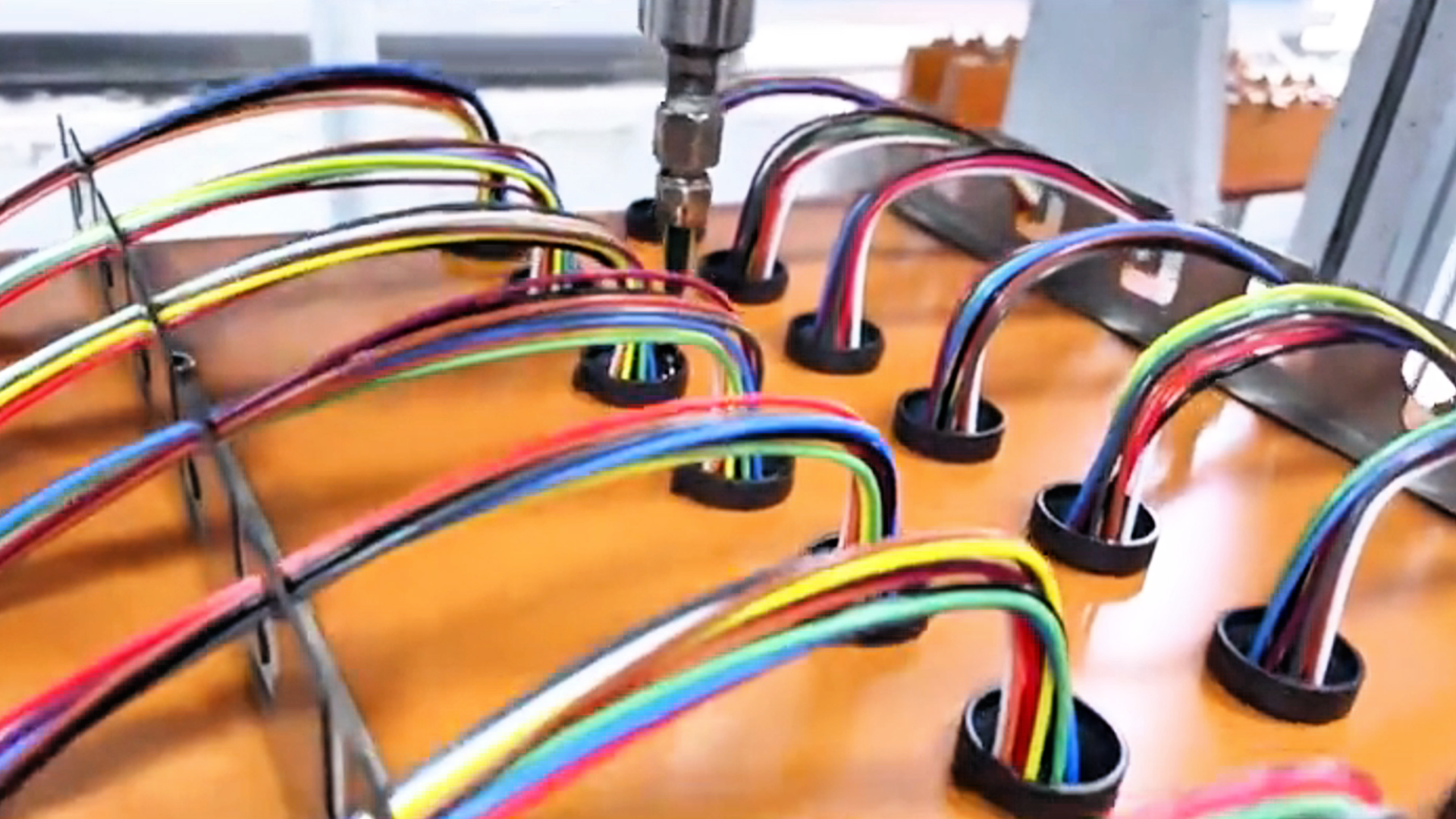

✅ Full-process service: from design, prototype to mass production, one-stop to meet your wiring harness needs

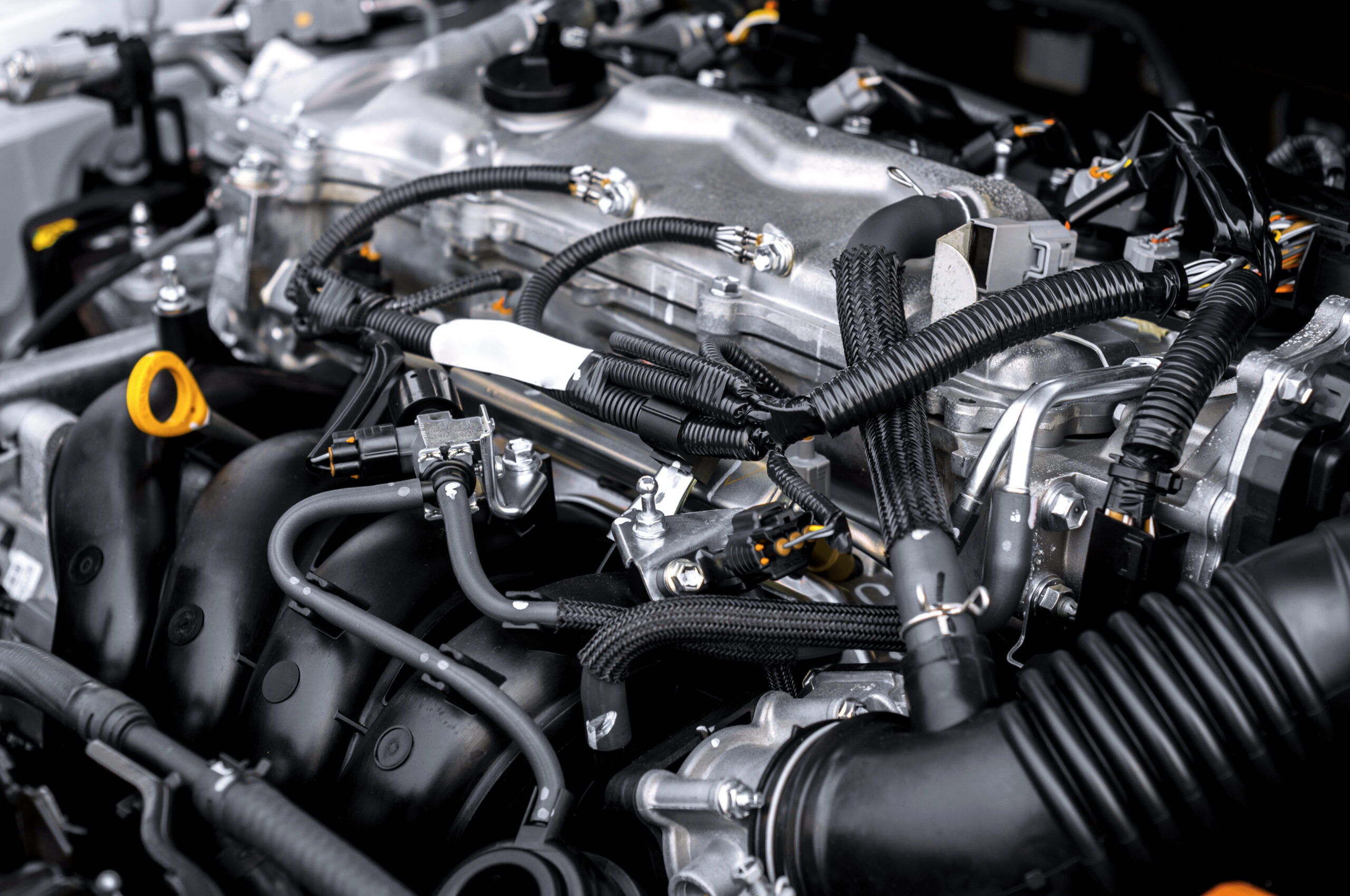

✅ Industry experience: Serving automotive, industrial, medical, consumer electronics and other fields, we understand the special requirements of different application scenarios.

✅ High-precision manufacturing: automated equipment + handmade precision technology to ensure stable performance of wiring harnesses.

✅ Rapid response: support small batch sampling and large-scale production, flexible response to your project needs.

Types of Manufacturing Services

offers end-to-end wire harness and cable manufacturing services, from design to production and testing, tailored for automotive, industrial, medical, and other industries.

Table of Contents

▶ Cable & Wire Harness Assemblies

Multi-Industry Compatibility:

- Automotive: CAN/LIN protocols, temperature resistance -40°C~125°C, USCAR-2 compliant.

- Industrial: EMI shielding (dual-layer structure), compatible with PLC systems and industrial robots.

- Medical: Biocompatible materials (e.g., silicone insulation), ISO 13485 certified.

▶ Value-Added Manufacturing

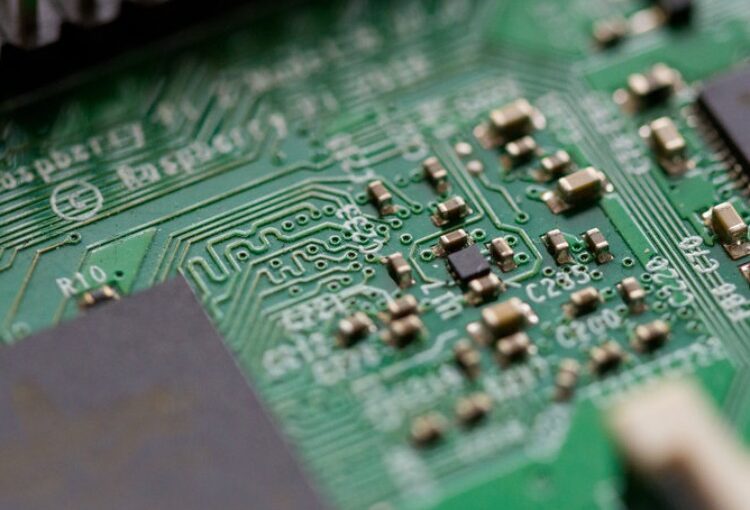

▶ Box Build

Integrated Design: Combines PCBs, harnesses, and power modules into enclosures with functional testing and thermal management.

Component Type |

Layout Principle |

|---|---|

|

Power Modules |

Bottom placement, isolated from sensitive circuits |

|

High-Frequency Circuits |

Independent shielding to reduce parasitic capacitance |

▶ Engineering & Prototyping

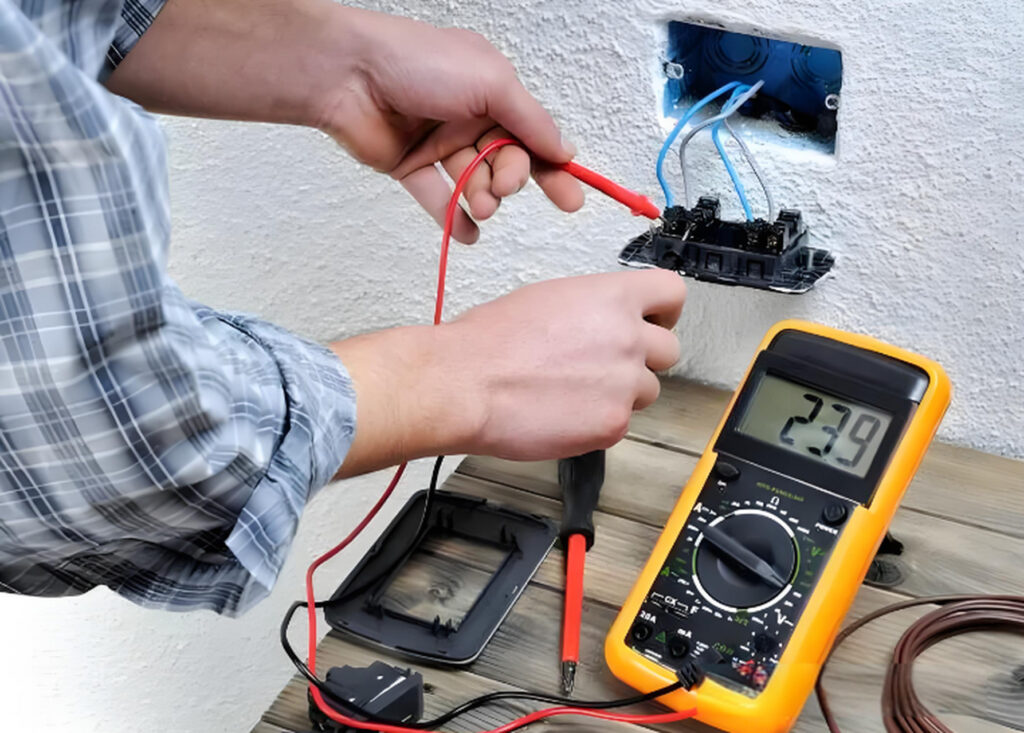

▶ Testing & Certification

▶ Customized Service Process

- Requirement Analysis: Submit drawings/samples to define specifications and compliance requirements.

- Design & Simulation: 3D modeling, DFM analysis, prototype validation.

- Production & Delivery: Automated manufacturing, strict quality control, global logistics (JOT delivery rate >98%).