Wire Harness Material Selection Guide

预计阅读时间: 7 分钟

As the “blood vessels” of electrical systems, the material selection of wire harnesses directly affects equipment performance, service life, and safety.

Different application scenarios have varying requirements for temperature resistance, conductivity, mechanical strength, and environmental adaptability of wire harnesses.

This article systematically analyzes the characteristics of various wire harness materials, from basic PVC to special fluoroplastics, from copper conductors to composite shielding structures, helping you make scientific and rational material selection decisions based on specific working conditions, cost budgets, and industry standards.

By Usage Environment

1. High-Temperature Environments

· Silicone Rubber Wire

- Temp. range: -60℃~200℃

- Features: Flexible, aging-resistant

- Applications: Industrial heaters, lighting

· PTFE/Teflon Wire

- Temp. range: -70℃~260℃

- Features: Chemically inert, low friction

- Applications: Aerospace, chemical industry

· Fiberglass Insulated Wire

- Withstands up to 500℃

- Features: Extreme heat resistance, high strength

- Applications: Furnaces, power equipment

2. Low-Temperature Environments

· Special PVC Wire

- Cold-resistant to -40℃

- Features: Maintains flexibility

- Applications: Freezers, arctic industries

· Silicone Rubber Wire

- Excellent low-temp performance

- Applications: Polar research, refrigerated transport

3. Wet/Underwater Environments

· Waterproof Cable

- Construction: Gel-filled or molded

- Rating: IP68

- Applications: Submersibles, outdoor lighting

· Marine Cable

- Features: Salt-resistant, anti-corrosion

- Standards: IEC 60092

4. Corrosive Environments

· Fluoropolymer Insulated Wire

- Resists acids, alkalis, solvents

- Applications: Chemical plants, electroplating

· Tinned Copper Conductor

- Prevents oxidation, longer lifespan

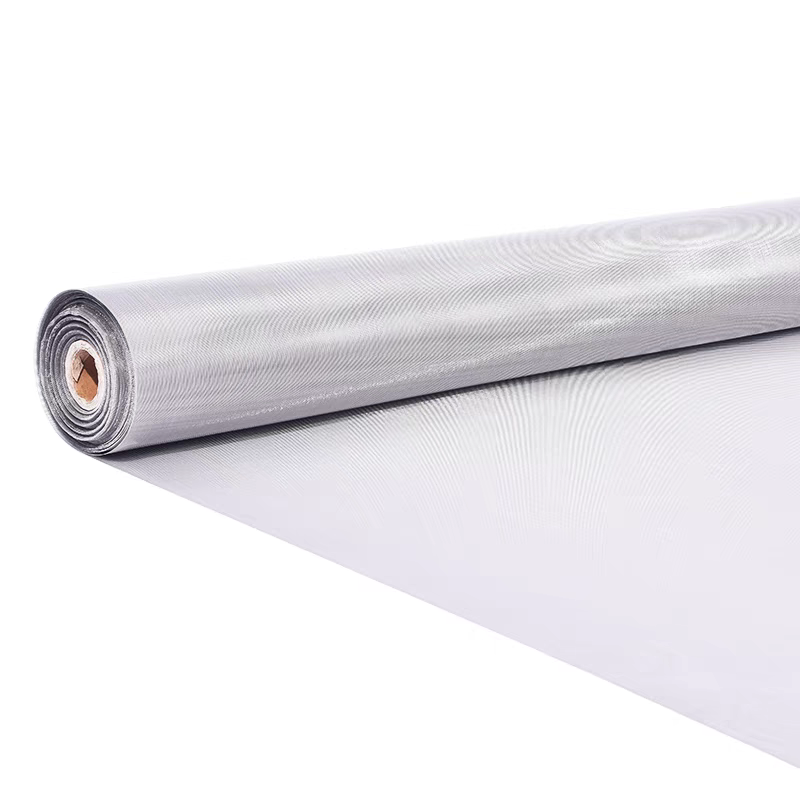

· Stainless Steel Braid

- Mechanical protection + EMI shielding

By Electrical Requirements

1. Voltage Levels

· Low Voltage (≤1kV)

- Material: PVC insulation

- Applications: Appliances, control circuits

`· Medium Voltage (1kV-35kV)

- Material: Cross-linked polyethylene (XLPE)

- Features: High dielectric strength

`· High Voltage (>35kV)

- Construction: Layered insulation + shielding

- Applications: Power transmission

2.Current-Carrying Capacity

· Cross-Sectional Area

- Typical: 0.5mm²~240mm²

- Standard: IEC 60287

· High-Frequency Use

- Litz wire reduces skin effect

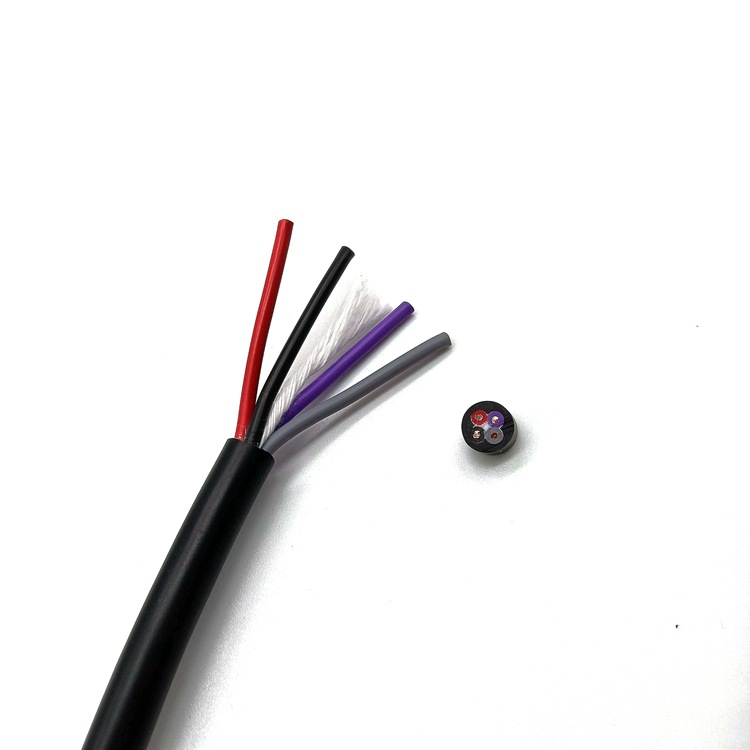

3. Shielding Requirements

· Single Shield (Aluminum Foil)

- Low-cost, anti-ESD

· Double Shield (Foil + Braid)

- Double Shield (Foil + Braid)

By Mechanical Requirements

1. Tensile Strength

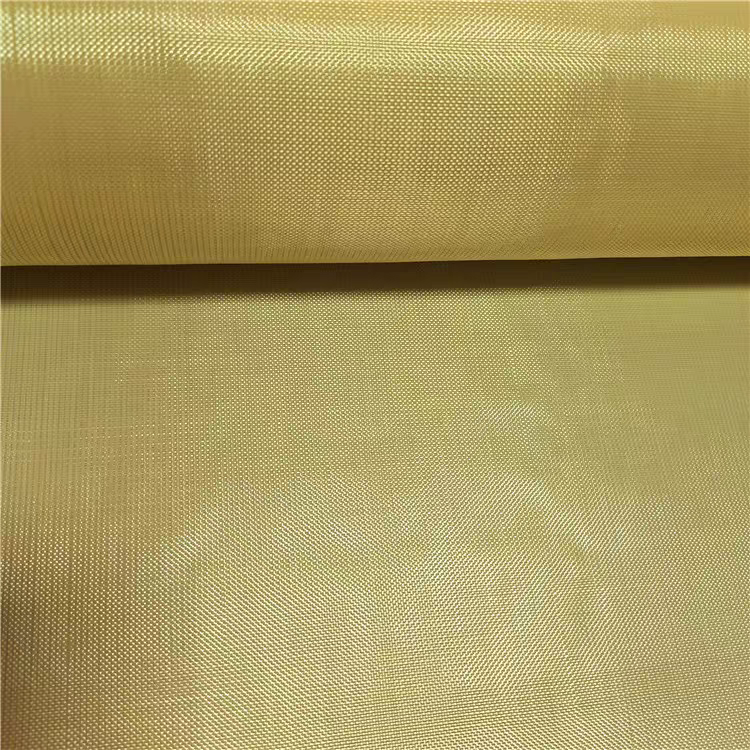

· Kevlar Reinforcement

- Strength: 5x stronger than steel wire

- Features: Lightweight, cut-resistant

- Applications: Drag chains, hoisting equipment

· Steel Wire Armor

- Construction: Helical steel wire layer

- Standard: IEC 60502

- Applications: Mining, construction sites

· Aramid Braid

- Features: High strength + flexibility

- Temp. range: -196℃~300℃

2. Abrasion Resistance

· Polyurethane Jacket

- Abrasion cycles: >50,000 (ISO 6945)

- Applications: Robot joints, automation

· Rubber Sheath

- Types: Chloroprene/EPDM/Nitrile

- Features: Oil-resistant + tear-resistant

· Abrasion-Resistant Braid

- Materials: Polyester/PBO fiber

- Color-coding available

3. Flex Life

· Fine-Stranded Conductor

- Standard: IEC 60228 Class 5/6

- Flex cycles: >1 million

· High-Elasticity Insulation

- Materials: TPE/TPU

- Elongation: >300%

· Special Construction

- Layered core arrangement

- Anti-twist design

By Cost & Environmental Factors

1. Cost-Effective Solutions

· Standard PVC Wire

- Price range: 0.1−0.5/m

- Service life: 5-8 years

- Limitation: Contains halogens

· Aluminum Conductor

- Conductivity: 61% IACS

- Applications: Fixed installation

- Note: Larger cross-section needed

2. Premium Solutions

· PTFE Wire

- Price range: 2−2−10/m

- Advantages: All-round performance

· LSZH Materials

- Smoke density: <15%(IEC 61034)

- Toxicity index: ≥80%(EN 50305)

3. Environmental Compliance

· RoHS-Compliant

- Restricted substances: Cd/Pb/Hg…

- Test standard: IEC 62321

· Recyclable Design

- Material labeling: PE/PP

- Separable construction

· Bio-Based Materials

- Sources: Castor oil/corn starch

- Carbon footprint reduction 30%+

For Special Applications

1. Automotive Wire Harnesses

· Thin-Wall Insulation

- Thickness: 0.2-0.4mm

- Standard: ISO 6722

· Oil/Heat Resistant

- Test condition: 150℃×3000h aging

- Materials: XLPO/Cross-linked PVC

2. Aerospace

· Ultra-Lightweight

- Weight: <20g/m(AWG22)

- Materials: Silver plated copper + PTFE

· Extreme Temp

- Range: -65℃~260℃

- Test standard: MIL-W-22759

3. Medical Cables

· Biocompatible

- Certification: ISO 10993

- Materials: Medical grade silicone

· Disinfectant-Resistant

- Resistance: Ethanol/Ethylene Oxide

- Test: 500 wipes

4. Robot Cables

· High-Flex Design

- Bend radius: 5×OD

- Life expectancy: >10 million cycles

· Torsion-Resistant

- Specification: ±180°/m

- Construction: Centre tensile element

Key Test Standards

| Performance | International Standard | Chinese Name |

| Flame Resistance | UL 94 V-0 | Vertical Burning Test |

| Oil Resistance | ISO 1817 | Rubber Liquid Resistance Test |

| Flexing | EN 50396 | Flexible Cable Bending Test |

| Smoke Emission | NFPA 262 | Plenum Space Burning Test |

Selecting the right wire harness material requires a comprehensive evaluation of environmental conditions, electrical requirements, mechanical strength, cost, and environmental compliance.

For specialized applications (e.g., automotive, aerospace, medical), adherence to industry-specific standards is critical. We recommend consulting technical specifications (UL, IEC, ISO) and professional suppliers to ensure optimal performance, safety, and long-term reliability.

No comments to show.

Leave a Comment