Cable & Wire Harness Assemblies

Welcome to KABOLUX’s comprehensive cable and wire harness assemblies services. We specialize in delivering high – quality, custom – designed solutions for a wide range of industries, including automotive, aerospace, medical, industrial, and consumer electronics. Our cable and wire harness assemblies are meticulously crafted to meet the specific requirements of each application, ensuring superior performance, reliability, and safety.

Why Choose Us

Professional Team

Our team consists of experienced engineers, technicians, and craftsmen who possess extensive knowledge and expertise in cable and wire harness design, manufacturing, and testing. They are committed to providing you with the best possible solutions and services.

Advanced Equipment

We are equipped with state - of - the - art machinery and tools, enabling us to produce cable and wire harness assemblies with high precision, efficiency, and consistency. Our equipment includes advanced cutting, stripping, crimping, and testing machines.

Quality Focus

Quality is our top priority. We have implemented strict quality control systems and procedures at every stage of production, from raw material inspection to final product testing. We use only high - quality materials and components to ensure the reliability and durability of our products.

Quality Assurance

Material Inspection

We carefully inspect all incoming materials to ensure they meet our stringent quality standards. This includes checking for defects, tolerances, and specifications.

Process Control

Our production process is closely monitored and controlled to ensure consistency and accuracy. We use statistical process control (SPC) to identify and correct any deviations in real – time.

Product Testing

Every cable and wire harness assembly undergoes rigorous testing, including electrical testing, mechanical testing, and environmental testing. This helps us identify any potential issues and ensure that our products will perform reliably in real – world conditions.

Benefits and Advantages

Custom Solutions

We understand that each customer has unique requirements. That’s why we offer fully customized cable and wire harness assemblies designed to meet your specific needs. Whether you need a simple harness for a consumer electronic device or a complex assembly for an aerospace application, we can deliver.

Cost - Effective

Our efficient production processes and economies of scale allow us to offer competitive pricing without compromising on quality. We work closely with our suppliers to ensure the best possible prices for materials and components.

Fast Turnaround

We strive to deliver your orders as quickly as possible. Our streamlined production流程 and dedicated team enable us to meet tight deadlines and keep your projects on schedule.

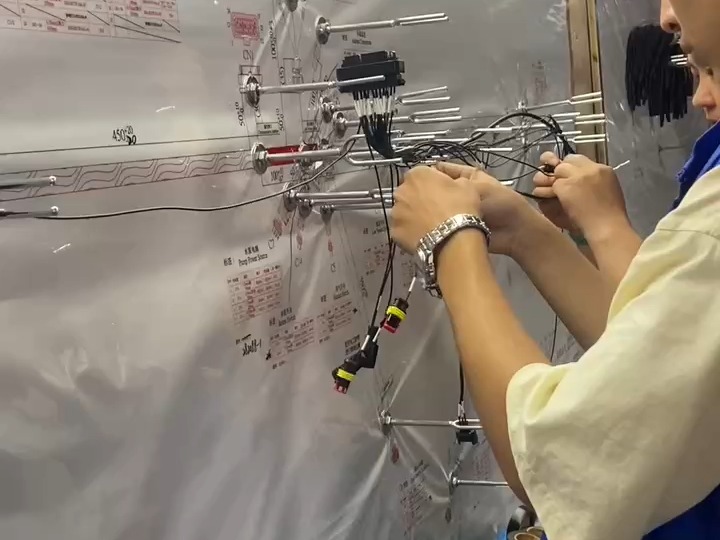

Manufacturing Process

The insulation is stripped from wire ends to prepare for connections, requiring careful control of stripping length and depth.

Stripping

Connectors are crimped onto stripped wire ends using crimping tools to ensure secure connections.

Crimping

Multiple wires are assembled into harnesses using techniques like tying and taping.

Assembly

Visual inspections and electrical testing are conducted to check for issues like short circuits. Advanced testing equipment is used to ensure reliability.

Quality Control

Common Specifications and Applications

- Automotive Wire Harnesses: Designed to withstand the harsh environment of automotive applications, our automotive wire harnesses meet industry - specific standards and regulations. They are used in various vehicle systems, such as engine management, lighting, infotainment, and safety systems.

- Industrial Control Wire Harnesses: Built to endure demanding industrial environments, these harnesses are used in machinery, automation equipment, and control systems. They provide reliable electrical connections for sensors, actuators, motors, and other industrial components.

- Medical Device Wire Harnesses: Our medical device wire harnesses meet the highest standards of safety, reliability, and biocompatibility. They are used in a wide range of medical equipment, including diagnostic devices, therapeutic equipment, and monitoring systems.

Material Selection and Customization

Conductor Materials

We offer a variety of conductor materials, including copper, aluminum, and copper alloys, to meet different electrical and mechanical requirements. The choice of conductor material depends on factors such as conductivity, strength, flexibility, and cost.

Insulation Materials

Our insulation materials include PVC, rubber, Teflon, and other high – performance polymers. The selection of insulation material depends on factors such as temperature resistance, chemical resistance, flexibility, and electrical properties.

Custom Configurations

We can customize the configuration of your wire harness assemblies according to your specific needs. This includes the number of conductors, wire gauges, connector types, and termination methods.

Support and Services

Design Assistance

Our engineering team can assist you with the design of your cable and wire harness assemblies. We can provide design recommendations, feasibility studies, and prototyping services to help you bring your ideas to life.

Technical Support

We offer technical support throughout the product lifecycle. Our team is available to answer your questions, troubleshoot issues, and provide solutions to any problems that may arise.

Sustainability and Environmental Considerations

- Eco - Friendly Materials: We strive to use environmentally friendly materials wherever possible. Our eco - friendly materials meet the latest environmental standards and regulations, such as RoHS and REACH.

- Waste Reduction: We implement waste reduction initiatives in our production processes to minimize our environmental footprint. This includes optimizing material usage, recycling waste materials, and reducing energy consumption.

Wires are cut to specific lengths using precision cutting tools. For example, in automotive harnesses, wires are cut based on vehicle design.

Cutting