Box Build

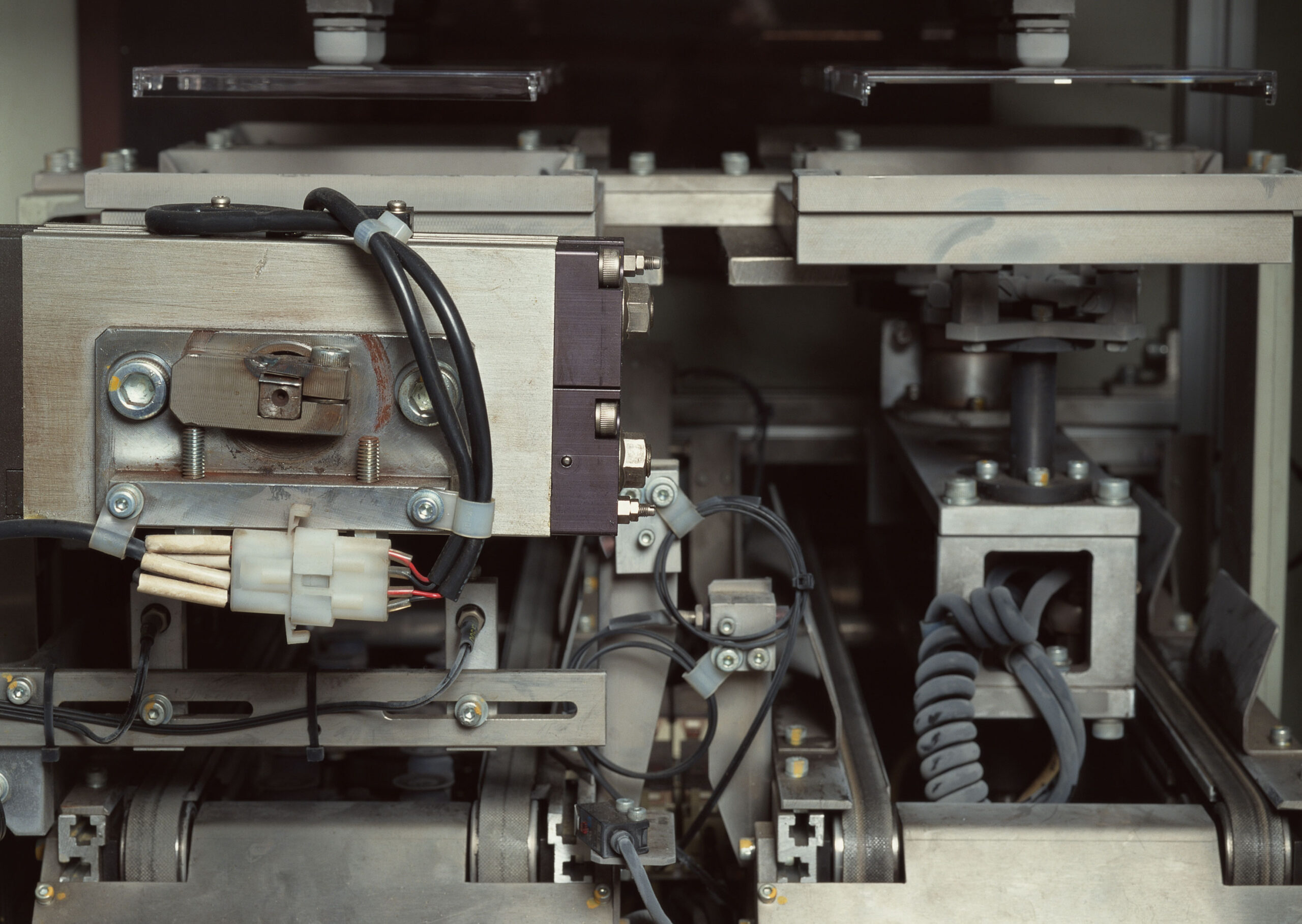

Box Build is a comprehensive manufacturing process that involves the assembly of various components into a fully functional product housed within an enclosure. It is widely used in numerous industries such as electronics, telecommunications, medical devices, and automation. Our Box Build service is designed to meet the unique requirements of each customer, offering high – quality and cost – effective solutions to bring your product ideas to life.

Why Choose Us

✅ Customized Solutions: We understand that every customer has specific needs. Therefore, we offer customized Box Build solutions tailored to your product design, specifications, and production volume requirements.

✅ Professional Team: We have a team of experienced engineers and technicians who specialize in Box Build manufacturing. They possess extensive knowledge and expertise in electronic and mechanical assembly, ensuring precise and efficient production processes.

Assembly Process

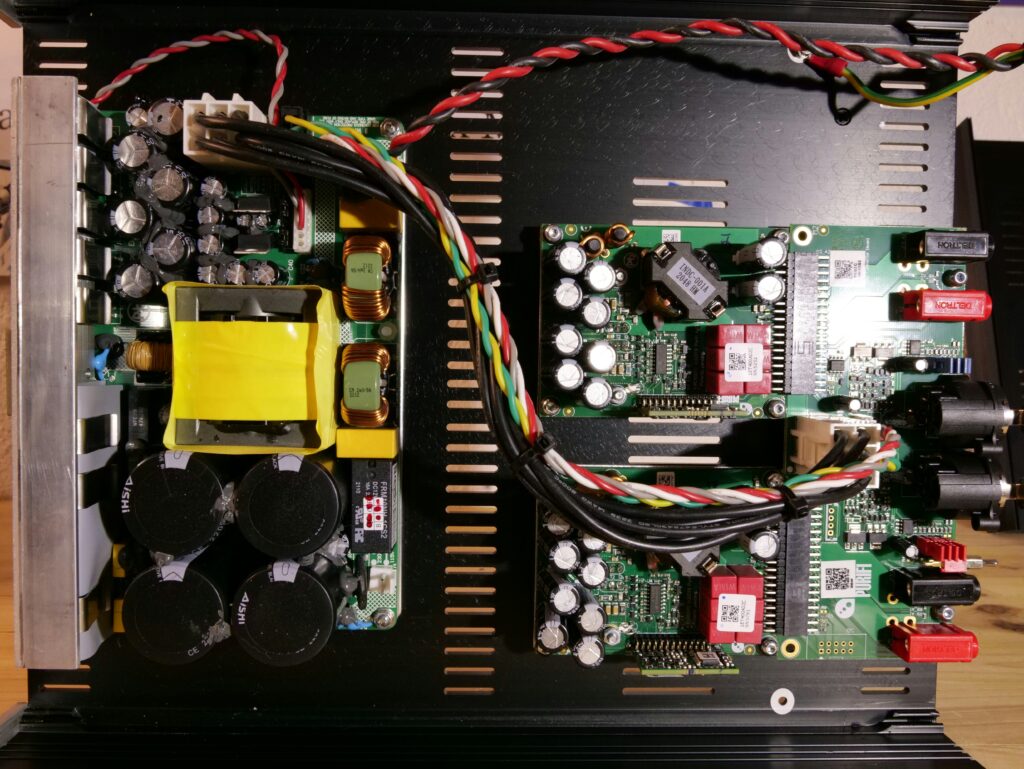

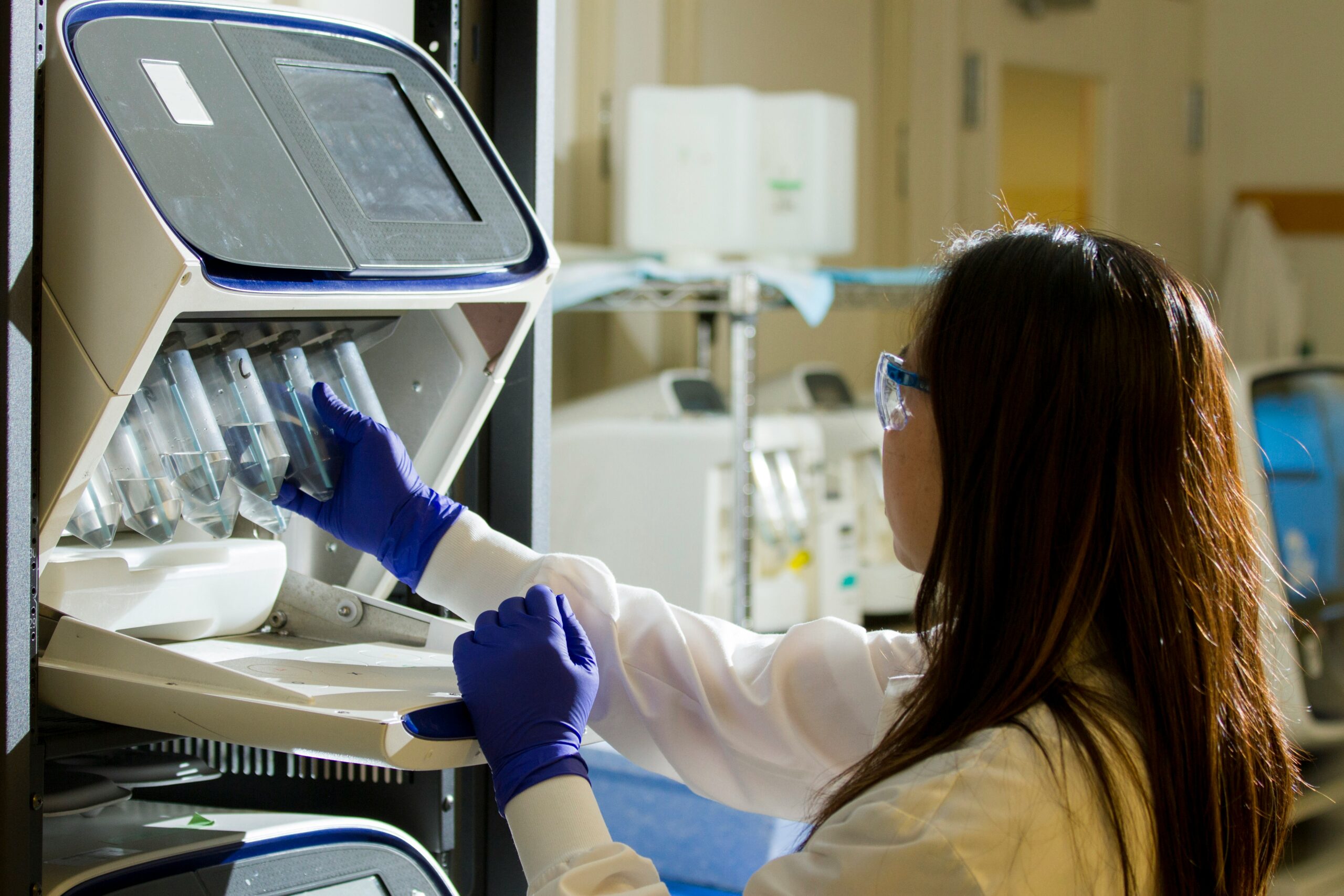

Component Installation

Components like circuit boards and wires are installed inside the enclosure. This requires precision to ensure all components fit correctly and function properly.

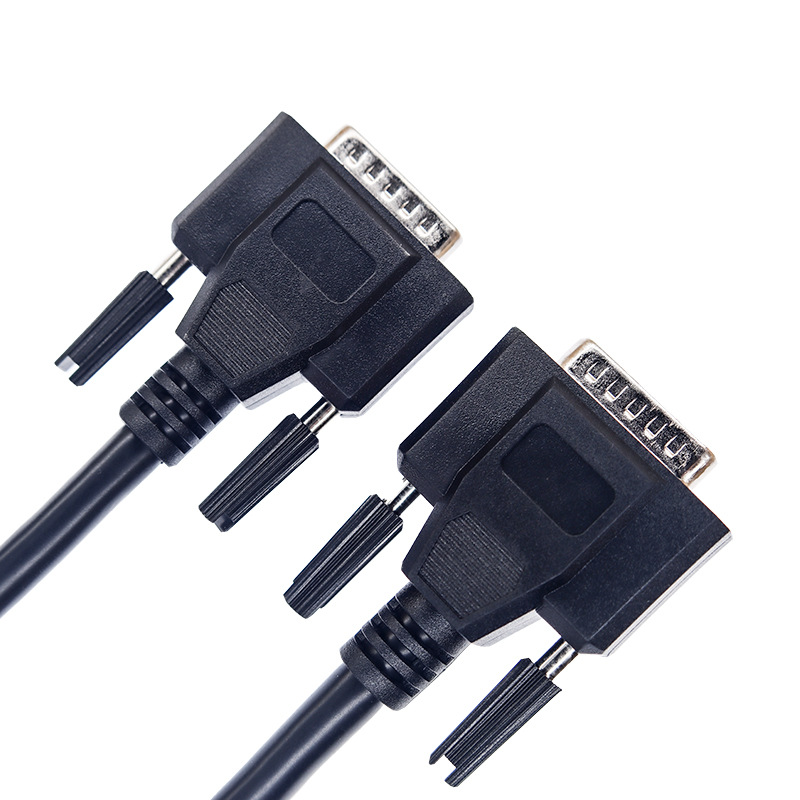

Connection and Wiring

Components are connected and wired according to design requirements. This step is critical to ensure electrical connectivity and product functionality.

Testing and Debugging

After assembly, products are tested and debugged to ensure functionality. This includes functional testing, electrical testing, and software testing if applicable.

Mitigate Risks, Deliver Flawless Custom Builds

End-to-End Customization: Tailoring physical layouts within enclosures to functional upgrades (e.g., specialized ports), aligning both form and function with your unique requirements.

Customization Design Customization / Functional Customization

Dual-Phase Quality Assurance: Real-time in-process defect correction for cost control + final real-world simulation testing, guaranteeing zero-defect compliance.

Testing and Validation In - Process Testing / Final Product Testing

End-to-End Project Stewardship: Strategic scheduling/resource/risk planning + seamless customer & cross-departmental coordination, ensuring frictionless box build execution.

Project Management Project Planning / Communication and Coordination

Dual-Channel Value Engineering: Strategic sourcing for material cost optimization + advanced manufacturing & automation upgrades, achieving quality-profit equilibrium without compromise.

Cost Control Material Cost Optimization / Production Efficiency Improvement

We provide warranty and support services to give customers peace of mind. This includes addressing any issues that arise during the warranty period and providing technical support.

After - Sales Services Product Maintenance / Warranty and Support

Quality Assurance

Strict Quality Control

We implement a rigorous quality control system throughout the entire Box Build process. From component inspection to final product testing, each step is carefully monitored to ensure compliance with quality standards.

Reliable Components

We source high - quality components from trusted suppliers. All components undergo strict quality testing before they are used in the assembly process to guarantee the reliability and durability of the final product.

Comprehensive Testing

After the assembly is complete, the products undergo a series of comprehensive tests, including functional testing, environmental testing, and safety testing. This ensures that the products meet the required performance and safety standards.

Common Specifications and Applications

Specifications

Applications

Dual Inspection Protocol: Scrutinizing enclosure for scratches/dents while testing functional integrity (e.g., button response, display), guaranteeing flawless appearance and reliable performance.

Quality Inspection Appearance Inspection / Functionality Testing