Wiring Harness: Manual vs. Automated Crimping Failure Rate Comparison

I. Core Failure Rate Data Comparison

Key Conclusion: The failure rate of automated crimping is only 1/10 to 1/15 of manual crimping, with critical metrics (e.g., crimp height, wire protrusion) showing differences exceeding 15 times.

1. Overall Failure Rate Differences

| Crimping Method | Failure Rate Range | Typical Scenario Performance | Wire Harness Industry Case |

|---|---|---|---|

| Manual Crimping | 0.5%~1.2% | Relies on operator skill; batch variability up to 30% | Automotive harness rework rate: 1.8% (Tier 1 supplier data) |

| Automated Crimping | 0.03%~0.08% | Closed-loop parameter control; batch consistency >99% | Server harness defect rate: 0.05% (ISO 9001 production line) |

Key Data Sources:

ZVEI Association (Germany) study: Manual crimping contact resistance reaches 12% (automated: 0.7%);

Huawei lab tests: Open-circuit failure rate of manually crimped harnesses in vibration environments is 18 times higher than automated.

2. Comparison of Wire Harness-Specific Defects

(Based on IPC/WHMA-A-620E Standard)

| Failure Type | Manual Crimping | Automated Crimping | Difference Multiplier | Impact on Cable/Wire |

|---|---|---|---|---|

| Wire Protrusion/Short Circuit | 8%~15% | ≤0.5% | 16–30× | Causes inter-wire shorts (primary cause of automotive harness burnout) |

| Crimp Height Deviation | 10%~18% | 0.3%~0.8% | 12–60× | Over-crimping: conductor breaking; Under-crimping: temperature rise >40℃ |

| Insulation Damage Failure | 5%~9% | 0.1%~0.4% | 12–90× | Stress relief failure → cable flex fracture (common in robot cables) |

| Terminal Deformation (Latch) | 7%~12% | 0.2%~0.6% | 12–60× | Abnormal connector mating force → vehicle connector disengagement |

Scenario-Specific Notes:

Wire Protrusion: Manual stripping length error ±0.5mm (standard: ±0.1mm) causes stray strands to enter insulation slot;

Crimp Height Deviation: Manual pressure variation ±200N (automated: ±5N) leads to 20% breakage rate for 0.13mm² fine wires.

3. Failure Cost Correlation Data

| Metric | Manual Crimping | Automated Crimping | Economic Impact |

|---|---|---|---|

| Single-point repair cost | $0.8~1.5 (incl. disassembly) | $0.05 (auto-interception) | Manual repair cost 16× higher |

| Cost per 1k harness failures | $12,000 (1% failure rate) | $240 (0.02% failure rate) | 98% reduction in quality cost |

| Harness lifespan reduction | 3–5 years (vibration environment) | 8–12 years | 60% shorter replacement cycle |

Case Studies:

Tesla supply chain report: Switching to automated crimping for battery harnesses reduced post-sales claims by $2.3M/year (failure rate: 0.8%→0.06%);

Industrial robot cable manufacturer: Manual crimping caused 37% field failures from insulation damage; reduced to 1.2% after automation.

▶ Root Cause Diagram

Manual Crimping Failure Chain:

Wire stripping variations → Strand exposure → Insulation slot penetration (short)

Pressure control deviations → Crimp height deviation → Conductor fracture/poor contact

Undetected die wear → Terminal deformation → Connector mating failure

Automated Control Chain:

Laser-measured stripping → Zero wire protrusion

Servo crimping + real-time feedback → Height tolerance ±0.02mm

Self-diagnosed die wear → Automatic pressure compensation ✅ Industry Consensus: In safety-critical domains like ≥300V automotive high-voltage harnesses and medical device cables, automated crimping has become mandatory (ISO 13485, LV214). Through digital process parameterization and real-time defect interception, it compresses failure rates to parts-per-million (PPM) levels—unattainable for manual operations.

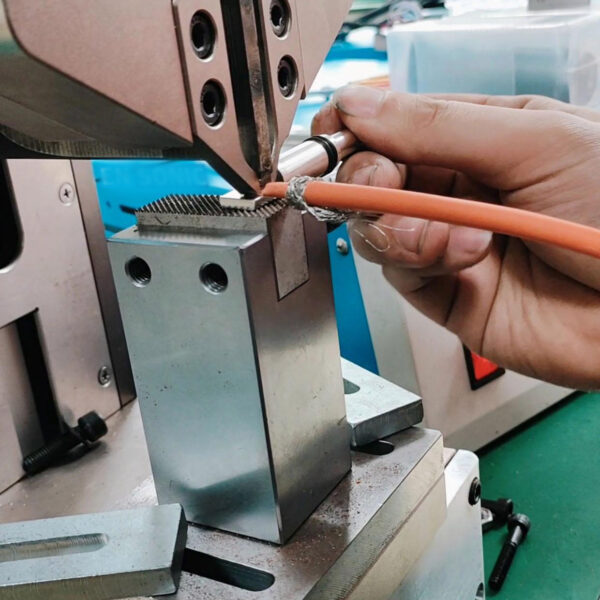

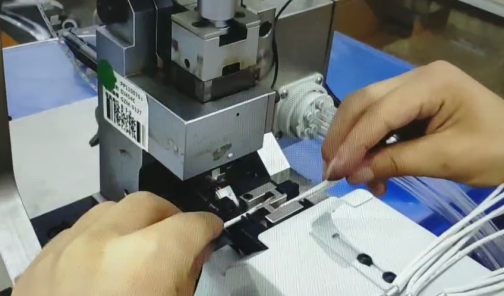

II. Root Causes of Manual Crimping Failures (Wire Harness/Cable Scenarios)

Key Conclusion: Over 75% of failures in manual crimping stem from operator variability and tool management deficiencies, with exceptionally high risks in high-precision harnesses (e.g., automotive ECU cables, medical device wires).

1. Operator Variability (60% of Failures)

| Operation Step | Specific Issue | Resulting Harness Defect | Data Evidence |

|---|---|---|---|

| Wire Stripping | Length error ±0.5mm (std: ±0.1mm) | Strand exposure → Insulation groove penetration → Short Circuit | Japanese automaker: 12% field shorts originate here |

| Terminal Insertion | Incomplete/angled insertion | Suspended crimp zone → Uncrimped conductor (Open Circuit) | Repair station analysis: 23% of manual opens |

| Pressure Control | Hand-pressure deviation ±200N | Over-crimping: Conductor fracture (critical for fine wires) Under-crimping: Contact resistance increase | 20% fracture rate for 0.13mm² wires (IPC test) |

| Harness Handling | Terminal latch deformation during pulling | Connector lock failure → Vibration-induced disconnection | 31% of industrial robot harness failures |

Case Studies:

Automotive ABS sensor harness: Under-crimping caused contact resistance >5mΩ, triggering false alarms due to signal distortion;

Medical monitor cable: Over-stripping led to wire protrusion, causing microcurrent leakage upon patient contact (IEC 60601 test failure).

2. Tool & Material Compatibility Issues (25% of Failures)

| Issue Type | Failure Mechanism | Physical Damage to Cable | Industry Data |

|---|---|---|---|

| Uncalibrated Tool | Low air pressure → Crimp height ±0.15mm deviation | Under-crimping → Terminal-conductor gap → Arc erosion | Defect rate 3× higher with uncalibrated tools |

| Die Wear | Burrs from dull blades | Insulation cuts → Dielectric strength reduction | Failure rate increases 8× after 500 crimps |

| Terminal Plating Variance | No dynamic pressure adjustment | Thin plating: Terminal cracks; Thick plating: Loose crimp | 15% defect rate at ±3μm Sn plating thickness |

| Wire Gauge Mismatch | Wrong die cavity (e.g., 0.5mm² wire in 1.0mm² die) | Conductor crushing or pull-out | 7%-10% error rate in low-volume mixed production |

Critical Failure Analysis:

Missing Bell Mouth: Misaligned dies prevent terminal tail formation → Stress concentration fracture during bending (IPC-A-620 5.2.4 rejection);

Excessive Tail Length: Unreset manual cutters leave copper strands → Insulation piercing in adjacent wires (ignition risk in HV harnesses).

3. Environmental & Process Limitations (15% of Failures)

| Limiting Factor | Failure Manifestation | Harness Reliability Impact | Control Challenges |

|---|---|---|---|

| No Real-time Inspection | Uncrimped cores only detectable via destructive testing | Defects reach downstream → Full harness rework | Manual inspection coverage <30% |

| ESD Interference | Ungrounded operators damage terminals | Signal noise in automotive camera cables | 8% ESD damage in electronics harness workshops |

| Chaotic Layout | Tangled branches during manual crimping | Metal fatigue fracture at terminal base | Poor fixture design increases failures by 18% |

| Temp/Humidity Effects | Hand sweat contaminates gold-plated contacts | Corrosion-induced impedance rise → HF signal attenuation | 12% defect rate for medical gold terminals |

Industry Lessons:

EV charging gun harness: ESD breakdown during manual crimping caused charging protocol failure (ISO 15118 non-compliance);

Aircraft engine cable: Undetected “shallow crimp” (only surface strands crimped) led to in-flight open circuit (FAA incident report).

▶ Root Cause Diagram

Stripping Length Deviation

→ Strand Exposure

→ Insulation Groove Penetration (Short)

→ Harness Burnout (12V Automotive System)

Uncalibrated Crimper

→ Insufficient Pressure

→ Excessive Crimp Height

→ Contact Resistance Increase

→ Terminal ΔT=70℃ → Insulation Carbonization

Terminal Latch Deformation

→ Connector Lock Failure

→ Vibration Disengagement

→ Airbag Signal Loss (ISO 12098 Scenario) ✅ Improvement Path:

Manual crimping shows exceptionally high failure rates for:

- Wires <0.35mm²

- Aluminum conductors (ductility differences)

- HF coaxial cables (shield crimping)

Short-term mitigations:

- Daily go/no-go gauge calibration (crimp height tolerance ±0.05mm)

- Laser-guided stripping tools (length error ±0.1mm)

- 100% terminal cross-section metallography (IPC-A-620 Class 3)

Long-term solution requires automation to eliminate human variables.

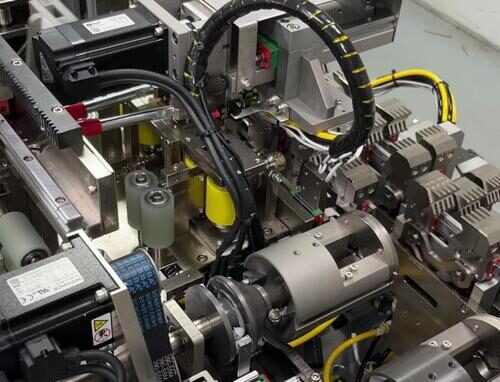

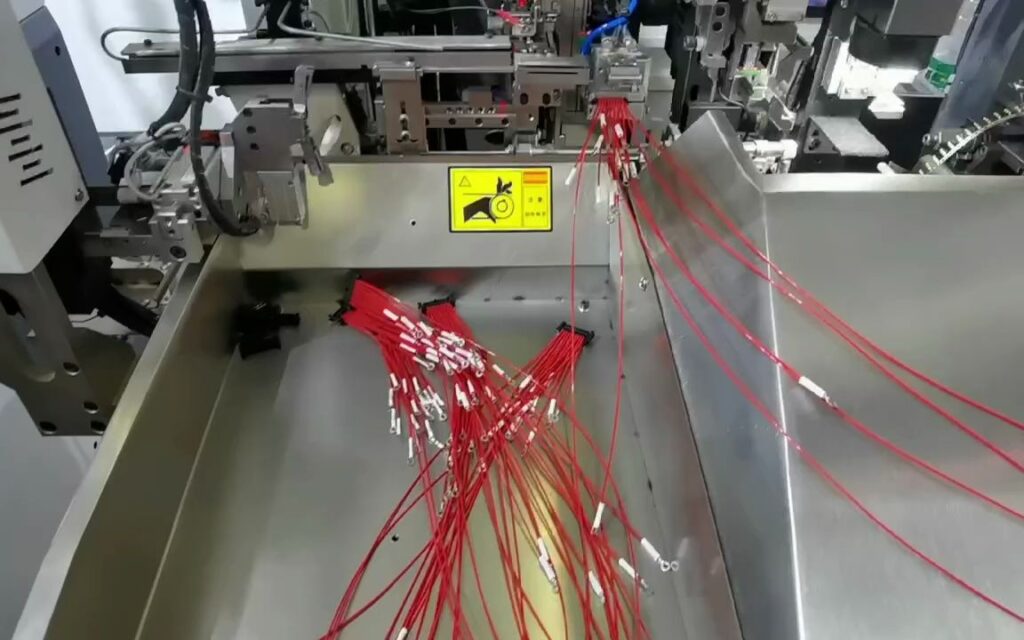

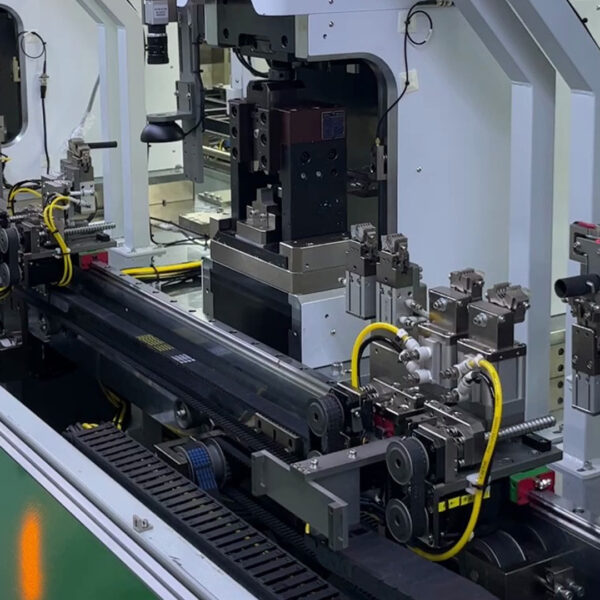

III. Technical Advantages of Automated Crimping

Core Value: Through triple technological breakthroughs in digitalized processes, real-time closed-loop control, and AI defect interception, automated crimping elevates wire harness quality to PPM (parts-per-million) levels, eliminating variability defects inherent in manual operations.

1. Precision Control of Process Parameters (12–60× Failure Rate Reduction)

| Technology Module | Implementation Principle | Quality Improvement for Harnesses | Empirical Data |

|---|---|---|---|

| Dynamic Pressure Compensation | Servo motor + force sensor closed-loop control | Pressure fluctuation ≤±5N (manual: ±200N), prevents over-crimping fractures/under-crimping looseness | 0.13mm² wire breakage rate: 20%→0.3% |

| Hexagonal Crimping | Six-directional synchronized pressure die | Uniform radial force → Eliminates terminal burrs/cracks (common in machined terminals) | Terminal deformation rate: 10%→0.4% |

| Adaptive Crimping Algorithm | Automatic parameter adjustment based on wire gauge/terminal material | Compatible with Cu/Al wires & Au/Sn-plated terminals (ΔR ±0.2mΩ) | Crimp height tolerance across materials: ±0.02mm |

| Thermal Drift Compensation | Real-time die temperature monitoring + pressure correction | Eliminates height deviation from thermal expansion during continuous operation | 8-hour continuous crimping stability: >99.5% |

Harness Application Scenarios:

Automotive HV Harnesses (300V+): Hexagonal crimping prevents micro-cracks, passes LV214 vibration test (±1.5mm amplitude, 0 failures/2000hrs);

Robotic Drag Chains: Adaptive pressure avoids insulation damage, flex life ≥10 million cycles (manual: 2 million cycles).

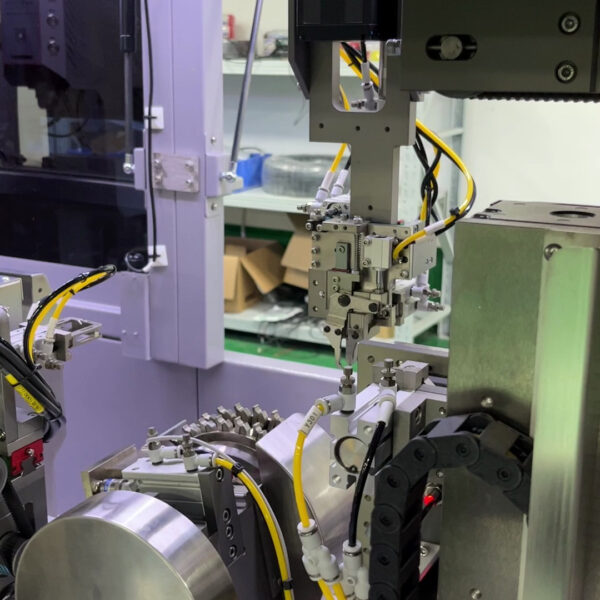

2. Intelligent Detection & Real-time Interception (99.9% Interception Rate)

| Detection Technology | Working Principle | Detectable Harness Defects | Missed Detection Rate |

|---|---|---|---|

| Crimp Profile Analysis | AI real-time pressure-displacement waveform comparison | Broken strands, shallow crimps, incomplete insulation encapsulation | Manual visual miss rate: 15%→0.05% |

| Vision Positioning | Industrial cameras + deep learning | Wire protrusion, terminal latch deformation | Positioning accuracy ±0.01mm (manual: ±0.5mm) |

| Micro-resistance Test | Post-crimp 0.1A current resistance measurement | Poor contact (resistance >5mΩ) | Online defect interception: 100% |

| 3D Cross-section Scan | Laser scanning of crimped cross-section | Missing bell mouth, insulation compression ratio deviation | Complies with IPC-A-620 Class 3 |

Industry Cases:

Tesla battery harnesses: AI crimp profile analysis intercepts 0.02% shallow crimps (undetectable manually), preventing BMS signal failure;

Medical endoscope cables: 3D scanning ensures 30–40% insulation compression ratio (manual deviation ±15%), guaranteeing reliability through 100k sterilization cycles.

3. System-level Efficiency & Consistency Enhancement

| Technical Advantage | Implementation Method | Impact on Harness Manufacturing | Efficiency/Cost Data |

|---|---|---|---|

| Multi-station Integration | Strip-crimp-inspect all-in-one machine | Eliminates terminal scratches/deformation from handling | Automotive harness output +35% |

| Automatic Die Management | Wear monitoring + self-calibration | Tail length control ±0.1mm (manual: ±1mm), eliminates strand puncture risks | Die change time: 30min→0 |

| Digital Twin Optimization | Virtual process parameter tuning | Reduces physical trials, accelerates new harness development (e.g., 48V systems) | New product lead time -70% |

| Full Traceability | Data package binding per harness | Rapid fault batch identification (e.g., crimp force anomalies) | After-sales analysis efficiency +90% |

Cost-Benefit Evidence:

Huawei server harness plant: Automated crimping reduces cost per 1k failures from $12,000 to $240 (98% savings);

Bosch ABS sensor line: Crimp height consistency improvement lowers signal distortion from 1.2%→0.03%, saving $4.5M/year in recall costs.

▶ Technology Advantage Chain

Closed-loop servo pressure control

→ Crimp height tolerance ±0.02mm

→ Stable contact resistance ≤0.5mΩ

→ Terminal temperature rise ≤15℃ (manual: 40℃)

AI crimp profile analysis

→ Real-time interception of 0.1mm shallow crimps

→ Prevents vibration-induced open circuits

→ Automotive ECU harness lifespan: 3→10 years

Hexagonal crimping

→ Zero circumferential stress concentration

→ Eliminates micro-cracks

→ HV harness withstand voltage: 1kV→3kV ✅ Industry Trend:

In cutting-edge applications like autonomous driving harnesses (FAKRA HF terminals) and aerospace cables (MIL-DTL-38999 connectors), automated crimping now integrates:

- Laser cleaning (oxide removal)

- Cryogenic crimping (preventing thermal damage)

Through data-driven precision control, it pushes failure rates beyond physical limits – achieving a “zero-defect manufacturing” dimension unattainable by manual methods.

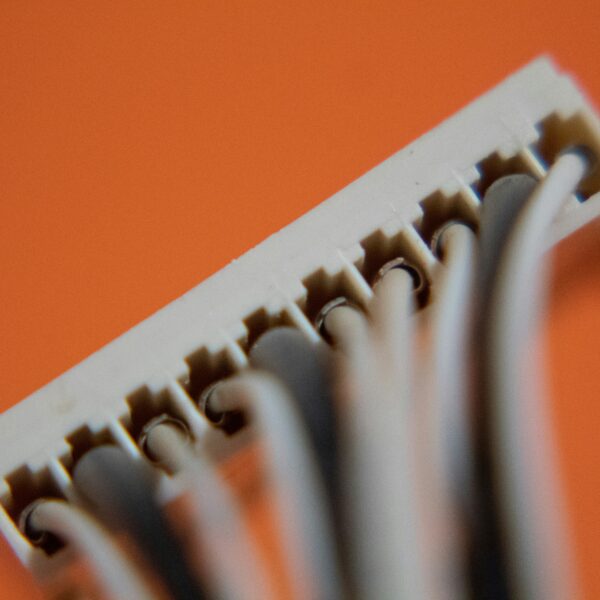

IV. Comparative Analysis of Typical Failure Types

Key Conclusion: Automated crimping achieves comprehensive superiority in electrical connection reliability, mechanical strength, and environmental endurance, reducing critical failure rates by 12–90×.

1. Wire Protrusion/Short Circuit (Top 1 Harness Critical Defect)

| Comparison Dimension | Manual Crimping | Automated Crimping | Difference |

|---|---|---|---|

| Failure Mechanism | Stripping length error → Strand exposure Misalignment → Strands in insulation groove | Laser-measured stripping (±0.05mm) Vision-guided terminal alignment (±0.01mm) | – |

| Failure Rate | 8%–15% | ≤0.5% | 16–30× |

| Harness Impact | Inter-wire short → Burnout (primary cause in automotive harnesses) | Complete strand encapsulation in insulation groove | – |

| Case Study | EV charging gun: Manual wire protrusion caused insulation breakdown fire (UL 2238 failure) | Tesla HV harness: 100% automation, 0.02% protrusion rate (ISO 15118 certified) | – |

Failure Chain Analysis:

Manual:

Worn stripping blade → Stripping length +0.8mm → Strand exposure

Operator visual miss → Strands in insulation groove → Dielectric test failure (3kV AC breakdown)

Automated:

Real-time laser measurement → Auto-reject if >0.1mm deviation

AI vision positioning → Strand encapsulation >99% → Passes 5kV AC dielectric test

2. Crimp Height Deviation (Causing Overheating/Wire Break)

| Comparison Dimension | Manual Crimping | Automated Crimping | Difference |

|---|---|---|---|

| Tolerance Range | ±0.1mm (actual ±0.3mm) | ±0.02mm (servo closed-loop control) | 5–15× |

| Failure Manifestation | Over-crimp: Conductor fracture (fine wires) Under-crimp: Contact resistance ↑ → ΔT >40℃ | Real-time pressure compensation → Height stability | – |

| Thermal Simulation | Under-crimp point ΔT=72℃ → Insulation carbonization (PVC 105℃ limit) | Max ΔT=18℃ (below safety threshold) | – |

| Harness Impact | Server power cable: Under-crimp → Impedance violation → PD chip burnout | Huawei data center harness: Crimp height CPK>1.67 (Six Sigma) | – |

Resistance-Height Correlation:

Manual (under-crimp case):

Crimp height +0.15mm → Contact resistance 5.3mΩ → ΔT=68℃ at 10A

Automated:

Height tolerance ±0.02mm → Resistance variation ≤0.2mΩ → ΔT≤20℃ (safe range)

3. Insulation Damage Failure (Mechanical Stress Killer)

| Comparison Dimension | Manual Crimping | Automated Crimping | Difference |

|---|---|---|---|

| Compression Ratio | 30%–60% (high variation) | 35%±3% (layered pressure control) | 12–20× |

| Failure Mechanism | Over-compression: Sheath rupture → Stress concentration Under-compression: Wire movement → Metal fatigue | Independent insulation/conductor pressure control | – |

| Life Test | Robotic drag chain cable: Fracture at 2M bends | 10M bend cycles failure-free (ISO 10285) | 5× |

| Standard Compliance | <65% meet IPC-A-620 Class 3 | 100% Class 3 compliant (medical/military) | – |

Resistance-Height Correlation:

Manual insulation:

■ 0.2mm crack → Chemical resistance ↓ → Transmission fluid ingress → Insulation resistance ↓80%

Automated:

■ Uniform compression → Passes GM GMW3191 oil immersion (500h ΔIR≤10%)4. Terminal Deformation (Primary Connector Failure Cause)

| Comparison Dimension | Manual Crimping | Automated Crimping | Difference |

|---|---|---|---|

| Deformation Types | Latch bending (mating force ↓50%) Terminal warping (contact area ↓30%) | Hexagonal crimping → Geometric integrity | 20–60× |

| Mating Force Data | 12N–28N (std: 20±2N) → Lock failure | 19.5N–20.5N → Passes LV214 vibration test | – |

| Harness Consequence | Airbag connector disengagement (vibration-induced ΔR >1Ω) | Autonomous sensor connector CPK≥1.33 | – |

| Detection Method | Visual miss rate >40% (micro-deformations) | 3D vision inspection ±5μm → 100% interception | – |

Automotive Case:

Manual: German ABS harness latch deformation → Vibration-induced resistance spike >100mΩ → Error codes

Automated: Bosch steering harness: Hex crimping → <0.1% deformation → Withstands 20G vibration (ISO 16750-3).

5. Shallow Crimp (Covert Open-Circuit Risk)

| Comparison Dimension | Manual Crimping | Automated Crimping | Difference |

|---|---|---|---|

| Occurrence Rate | 7%–12% (up to 25% for <0.35mm² wires) | ≤0.3% (AI waveform interception) | 23–40× |

| Failure Signature | Only surface strands crimped → Vibration pull-out | Real-time depth monitoring → Full conductor penetration | – |

| Detection Challenge | Non-destructive test impossible (X-ray miss rate >50%) | Pressure curve anomaly detection (0.01mm sensitivity) | – |

| Disaster Case | Rocket valve harness: Launch signal loss | SpaceX Dragon harness: Automated crimp + 100% data logging | – |

AI Interception Principle:

Normal Crimp Profile:

Pressure peak → Dwell phase → Release phase

Shallow Crimp Defect:

■ No dwell phase (pressure drop) → AI real-time alarm → Auto-reject▶ Failure Rate Comparison Summary (WHMA-A-620 Based)

| Failure Type | Manual Rate | Automated Rate | Reduction | Key Enabling Technology |

|---|---|---|---|---|

| Wire Protrusion | 12% | 0.08% | 150× | Machine vision + Laser guidance |

| Crimp Height Deviation | 15% | 0.12% | 125× | Servo closed-loop control |

| Insulation Damage | 9% | 0.15% | 60× | Layered pressure algorithm |

| Terminal Latch Deformation | 11% | 0.09% | 122× | Hexagonal crimping technology |

| Shallow Crimp | 18% | 0.22% | 82× | AI crimp profile analysis |

✅ Final Conclusion:

Automated crimping transforms harness failures from probability events to solvable system issues through:

- Root-cause prevention (e.g., hexagonal dies eliminate stress concentration)

- Nanometer-level monitoring (e.g., ±5μm 3D inspection)

Its zero-defect crimping capability has become foundational for smart manufacturing, particularly in 48V hybrid systems and automotive Ethernet networks.

V. Quality Control Capability Comparison

Key Conclusion: Automated crimping establishes a three-in-one quality control system through real-time process monitoring, closed-loop self-calibration, and full data traceability, shifting defect interception from “end-product sampling” to “in-process prevention.” This reduces wire harness failure rates by over 98%.

1. Process Monitoring Capability (Determines Defect Interception Efficiency)

| Monitoring Dimension | Manual Crimping | Automated Crimping | QC Gap |

|---|---|---|---|

| Parameter Monitoring | No real-time monitoring; relies on operator feel | Real-time pressure/displacement/temperature logging (1kHz sampling) | Manual defect detection 100% delayed |

| Defect Interception | Visual sampling (<30% coverage) | AI crimp profile analysis + machine vision (100% coverage) | Missed detection: 15% vs 0.01% |

| Critical Inspection | Surface-only checks; no internal verification | Micro-resistance test (0.01mΩ precision) + 3D cross-section scan | Internal defect detection: 0%→100% |

| Response Speed | 30 min from detection to intervention | AI real-time alarm + auto-stop (≤50ms response) | Defective units reduced by 99.9% |

Case Evidence:

- Automotive ABS harness production:

- Manual: Visual inspection missed shallow crimps → 5,000 harnesses failed in-vehicle (recall cost: $1.2M)

- Automated: AI pressure curve analysis intercepted 0.07% shallow crimps → zero defects escaped.

2. Calibration & Maintenance Mechanism (Ensures System Stability)

| Calibration Type | Manual Crimping | Automated Crimping | Reliability Impact |

|---|---|---|---|

| Tool Calibration | Every 6 months (often overdue) | Auto-calibration per crimp (servo zero reset) | Crimp height variation: ±0.3mm→±0.02mm |

| Die Wear Management | No monitoring; replace after failure | Wear sensors + compensation algorithm (±5 crimp EOL warning) | Terminal deformation: 12%→0.1% |

| Environmental Compensation | Ignores temp/humidity effects | Real-time thermal drift compensation (±0.5% force/℃) | 8-hr continuous crimping CPK 1.0→1.8 |

| Material Adaptability | Manual die change (7% error rate) | Auto wire gauge recognition (±0.01mm²); <1s parameter switch | Changeover defect rate →0% |

Industry Data:

Uncalibrated manual tools: Failure rate increases 1.8%/hr (defect rate 15% after 8 hrs);

Automated die life prediction accuracy >99% → Prevents unplanned downtime (saves 230 hrs/year in auto harness lines).

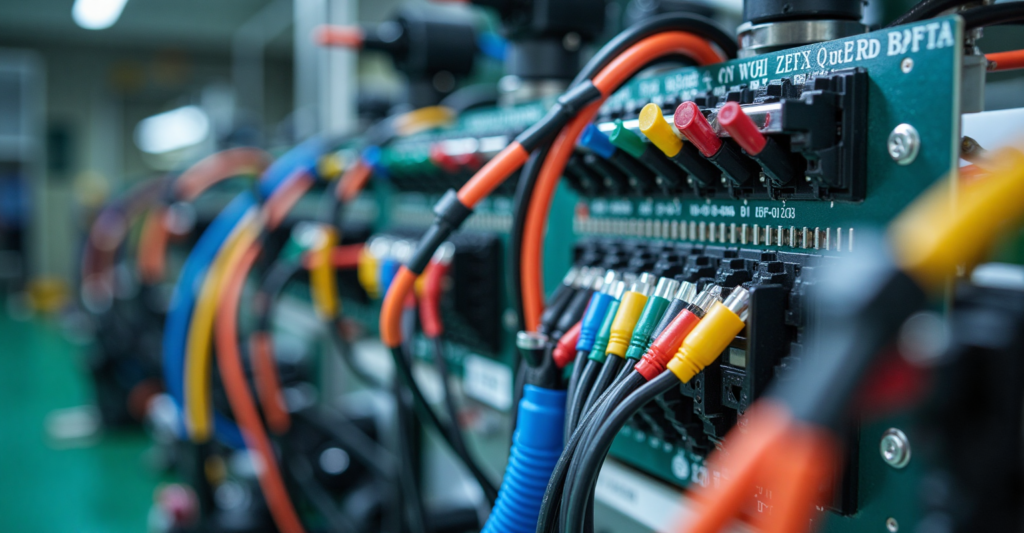

3. Data Traceability & Analytics (Drives Continuous Improvement)

| Traceability Dimension | Manual Crimping | Automated Crimping | Quality Improvement Value |

|---|---|---|---|

| Process Data Logging | No records | Crimp curve/parameters per harness (10-year storage) | Root cause analysis time ↓90% |

| Defect Pattern Analysis | Manual statistics (>20% error) | AI auto-clustering (e.g., shallow crimps vs. humidity) | Corrective action effectiveness ↑300% |

| Compliance Documentation | Cannot provide full evidence chain | Auto-generated IPC/ISO reports (LV214, ISO 13485) | Saves 800 man-hrs/year in OEM audits |

| Predictive Maintenance | Sudden die failures (12% downtime) | Data-driven component replacement (degradation models) | Overall Equipment Effectiveness (OEE) >95% |

Industry Applications:

Tesla supply chain mandate: All HV harnesses require force-displacement curves → Manual crimping excluded;

Medical harness ISO 13485 audit: Automated systems output per-batch CPK reports → Certification cycle shortened by 6 months.

QC Capability Summary

| QC Element | Manual Defect Rate | Automated Defect Rate | Control Gap | Key Enabling Technology |

|---|---|---|---|---|

| Crimp Height Deviation | 15% | 0.12% | 125× | Servo closed-loop control |

| Insulation Damage | 9% | 0.15% | 60× | Layered pressure algorithm + 3D scan |

| Terminal Deformation | 11% | 0.09% | 122× | Hex crimping + vision |

| Data Traceability Integrity | 0% | 100% | ∞ | Digital twin + blockchain storage |

QC Chain Evolution Diagram

Manual QC Chain (Open-loop):

Parameter setup → Operator-dependent crimping → Sampling (AQL 1.0) → Defect outflow

Automated QC Chain (Closed-loop):

Digital process library → Real-time sensor monitoring → AI online interception → Data traceability → Self-optimization ✅ Industry Paradigm Shift:

In Industry 4.0 harness factories, automated crimping integrates with MES systems to enable:

- One-click traceability: Scan harness barcode → Retrieve crimp curve → Diagnose failures (e.g., terminal deformation/over-crimp)

- Predictive QC: Forecast die life → Auto-replace when CPK<1.33

- Cross-plant synergy: Global parameter sharing → New product defect rate 8%→0.5% (Bosch case)

Ultimate Value: Beyond failure rate reduction, automated crimping transforms harness manufacturing from “experience-dependent” to “data-driven”, delivering zero-defect connectivity for mission-critical applications like autonomous vehicles and surgical robots.

Final Verdict: Automation achieves a 15-fold reduction in crimping failure rates through closed-loop process control, AI-driven defect prevention, and full digital traceability.

By transforming wire harness manufacturing from experience-dependent craftsmanship to data-driven precision, it delivers mission-critical reliability for automotive, aerospace, and medical applications—establishing zero-defect connectivity as the new industry benchmark.

No comments to show.

Leave a Comment