Cooling Measures for Overloaded Harnesses

Table of contents

Material Optimization

1. High-Conductivity Materials

Key strategy: Reduce Joule heating by minimizing conductor resistance.

| Material Type | Characteristics and Advantages | Application Scenarios |

|---|---|---|

| Copper Alloy Wires | Low resistivity (<1.7×10⁻⁸ Ω·m), cost-effective for high-current applications. | EV high-voltage harnesses, industrial power distribution. |

| Silver-Plated Wires | 30%~50% lower contact resistance, anti-oxidation, stable for high-frequency signals. | Aerospace, precision instrument harnesses. |

| Nickel-Based Alloys | Withstand >400°C, excellent creep resistance. | High-temperature environments (e.g., engine compartments). |

2. Insulation & Thermal Management Materials

Goal: Enhance thermal conductivity of insulation layers while ensuring electrical safety.

(1)High-Temperature Insulation

- PTFE:Temperature range: -200℃~260℃, chemically inert, low friction coefficient.

- Silicone Rubber:High flexibility, 180℃~250℃ resistance, ideal for complex bending harnesses.

(2)Thermal Conductivity Enhancement

| Methodology | Principle | Effect |

|---|---|---|

| Alumina Particles | Mix 10%~30% alumina (thermal conductivity 30 W/m·K). | 3~5× higher conductivity, 15%~20% cost increase. |

| Thermal Grease Coating | Coat harness with boron nitride-enhanced grease. | 40%~60% lower interfacial thermal resistance, requires maintenance. |

3. Innovative Composite Materials

| Materials | Structural Design | Comprehensive Advantages |

|---|---|---|

| Metal-Polymer Laminates | Alternating copper foil and polyimide layers. | High thermal conductivity (5~8 W/m·K) + electrical insulation. |

| Carbon Fiber-Reinforced Wires | Carbon fiber coating on copper core. | 30% weight reduction, 10%~15% higher current capacity. |

▶ Summary

• Cost-effective: Copper alloy + silicone rubber + alumina filler

• Extreme conditions: Silver-plated wires + PTFE + liquid cooling

Structural Design

1. Layout Optimization

Objective: Minimize heat concentration and enhance cooling efficiency through spatial distribution optimization.

(1)High-Temperature Insulation

- Wire Harness Pitch Control: Maintain spacing ≥2× wire diameter (or ≥10 mm) between adjacent harnesses.

- Partition Management: Separate high-power and low-power harnesses in different channels.

(2)Layered Isolation

| Hierarchical Design | Functional Description | Application Examples |

|---|---|---|

| EM Shielding Layer | Metal braid layer blocks EMI and reduces eddy current heating. | High-frequency communication harnesses, automotive sensor harnesses. |

| Thermal Barrier Layer | Ceramic fiber or aerogel layers reflect radiant heat. | Engine compartment harnesses, industrial high-temperature equipment. |

2. Heat Dissipation Structures

Core principle: Accelerate heat transfer and dissipation via structural design.

(1)Passive Cooling

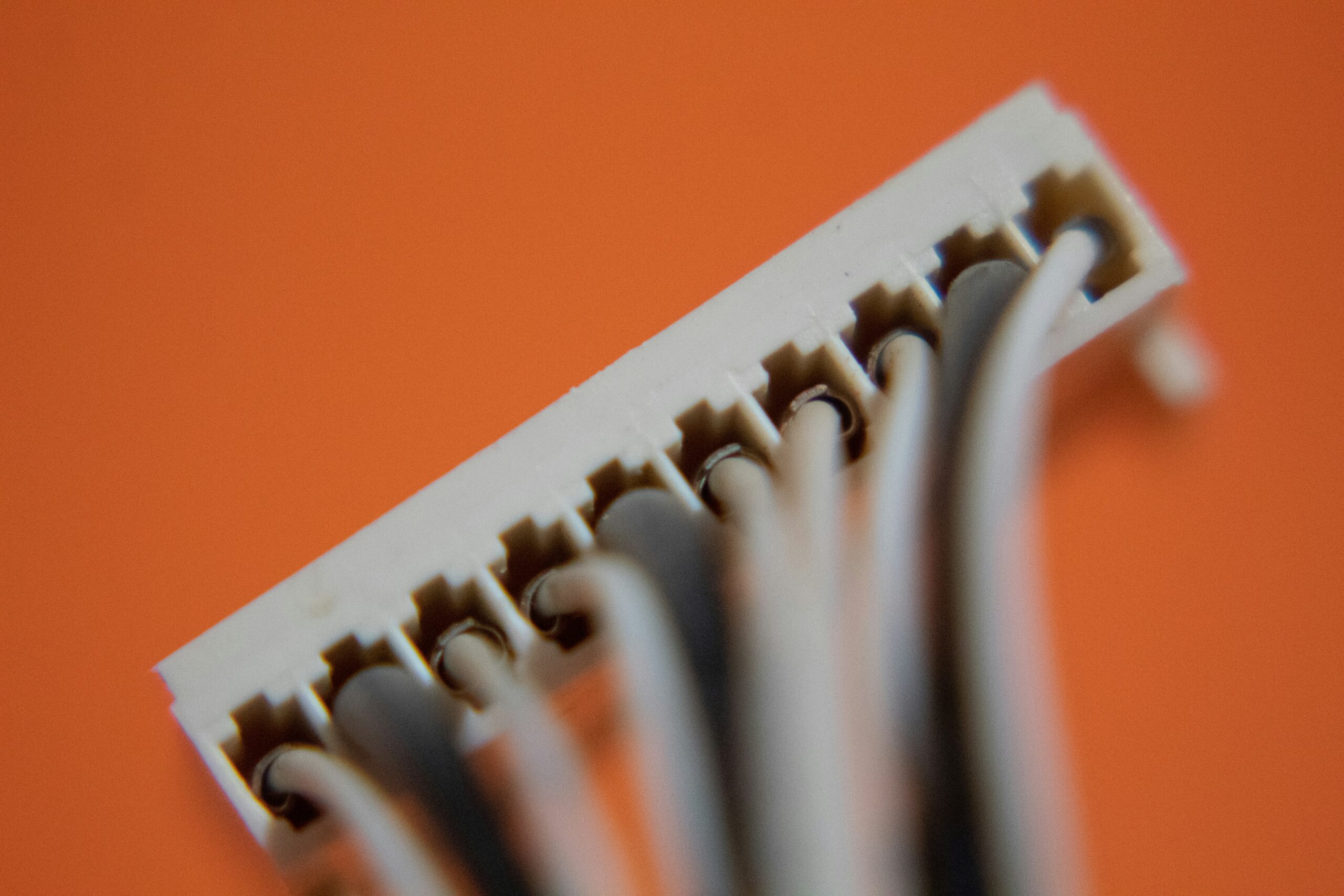

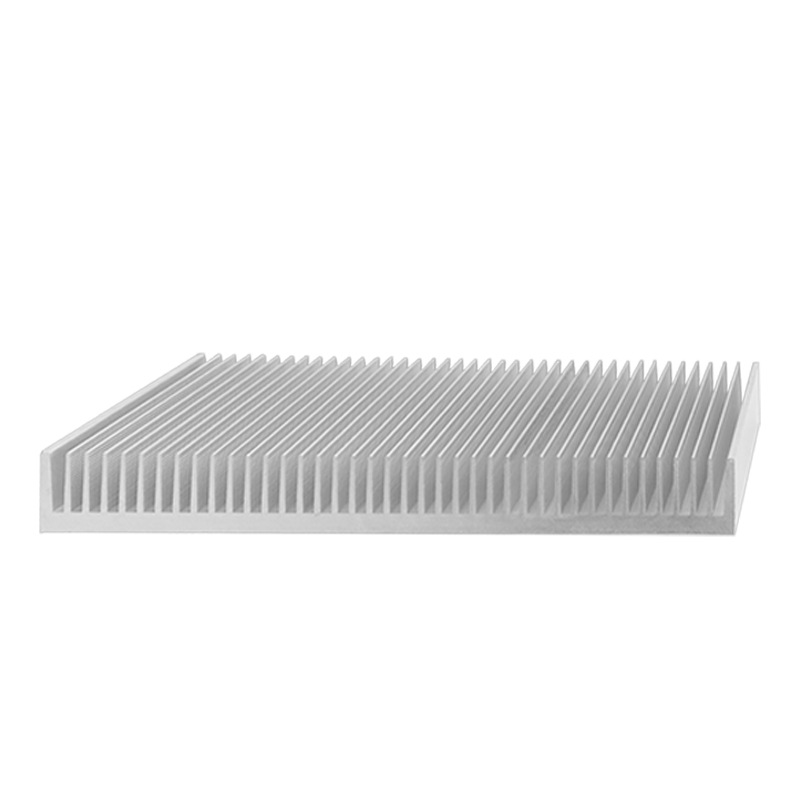

- Metal Heat Sinks:

Wrap harnesses with aluminum/copper fins to enhance natural convection.

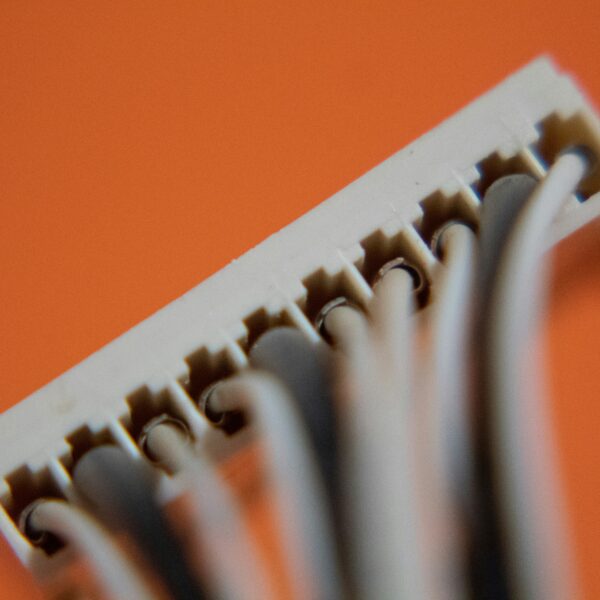

Example parameters: Fin thickness 0.5~1 mm, density 5~8 fins/cm. - Corrugated Conduit Design:

Corrugated tubes (nylon or metal) increase turbulent airflow for cooling.

(2)Active Cooling Integration

| Structural Solutions | Working Principle | Applicable Scenarios |

|---|---|---|

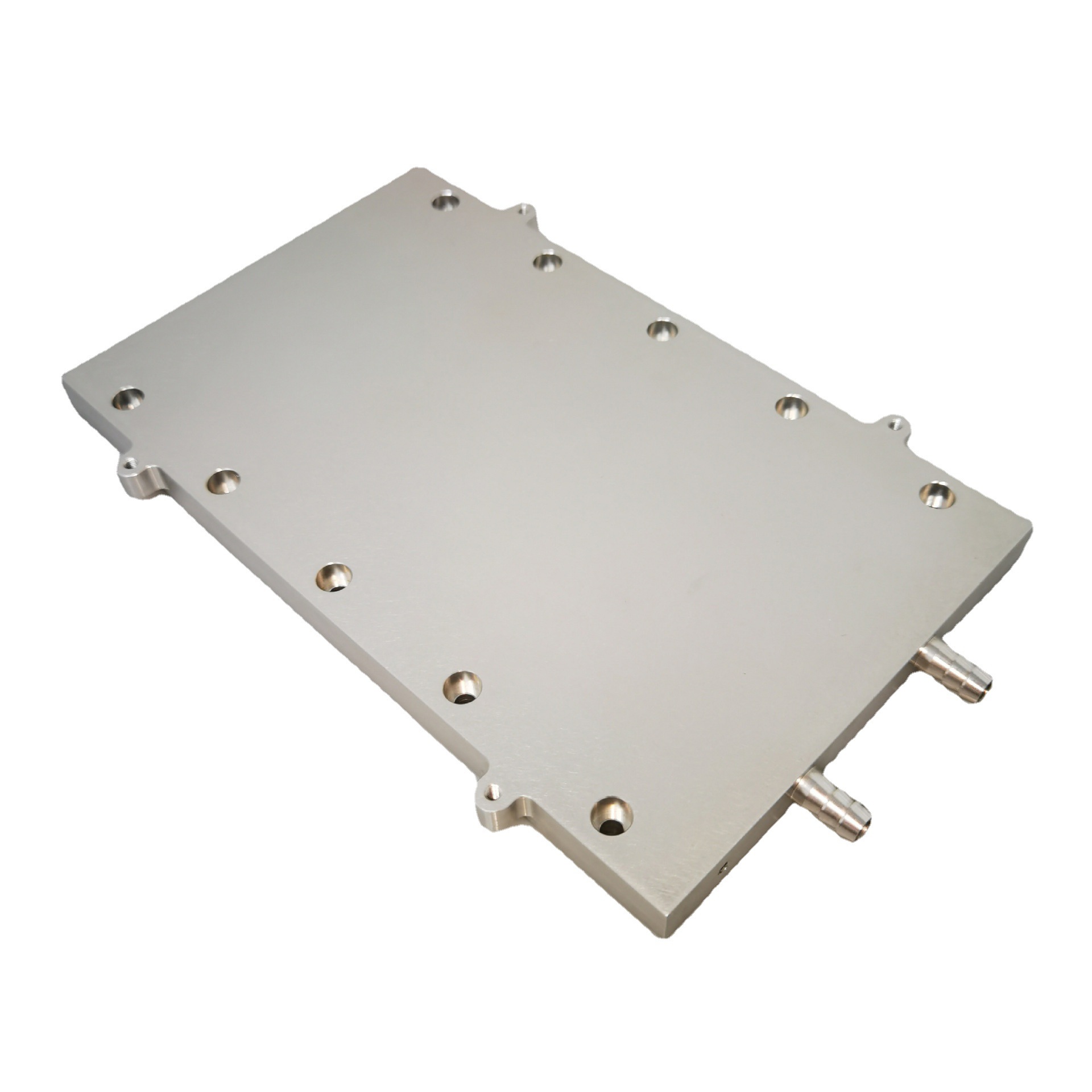

| Embedded Liquid Channels | Micro liquid channels in cable jackets circulate coolant. | Data center harnesses, EV battery pack harnesses. |

| Airflow Guide Grooves | Surface grooves guide airflow with fans (≥3 m/s). | Server racks, industrial control cabinets. |

3. Modular Design

Advantage: Reduce localized heat load and simplify maintenance.

| Module Type | Design Features | Cooling Benefits |

|---|---|---|

| Detachable Connectors | Plug-in terminals allow quick disconnection of high-heat modules. | 50% faster cooling maintenance. |

| Segmented Shielding Covers | Modular metal covers enable localized cooling. | 15%~20% hotspot temperature reduction. |

4. Mechanical-Thermal Co-Design

Key focus: Balance mechanical strength and thermal performance.

- Thermal Expansion Compensation Structures: Spring coils or elastic brackets compensate for thermal expansion (≥5 mm/m).

- Lightweight openwork design: Lightweight honeycomb structures reduce weight by 30% and improve heat dissipation.

▶ Summary

The structural design achieves efficient cooling through space layout optimization, heat dissipation structure innovation and modularity. For example:

- Layered Isolation + Embedded Liquid Channels

- Corrugated Tubes + Airflow Guide Grooves

Active Cooling Systems

1. Forced Air Cooling

Advantage: Low cost and easy deployment through enhanced airflow.

(1)Integrated Fans

- Axial Fans: Mounted near harnesses with 2~5 m/s airflow, improving efficiency by 30%~50%.

Applications: Server racks, EV battery harnesses. - Centrifugal Fans: High-pressure airflow penetrates dense harness areas (pressure >200 Pa).

Applications: Industrial control cabinets, aerospace systems.

(2)Airflow Path Optimization

| Design Methodology | Functional Description | Performance Enhancement |

|---|---|---|

| Air Guide Plates | Direct airflow to high-heat harnesses (e.g., copper plates). | Local temperature reduction: 15~25℃. |

| Honeycomb Ducts | Hexagonal structures reduce turbulence and distribute airflow evenly. | Overall efficiency improvement: 20%~30%. |

2. Liquid Cooling

Superiority: Heat transfer capacity significantly exceeds air cooling.

(1)Liquid Cooling Solutions Comparison

| Type | Principle of operation | Coolant | Scenario |

|---|---|---|---|

| Microchannel Cold Plates | Metal plates with microchannels (0.1~0.5 mm) attached to harness surfaces. | Water-glycol mixture | Data centers, high-power electronics. |

| Immersion Cooling | Submerge harnesses in dielectric fluid (e.g., fluorocarbon). | Fluorocarbon/Mineral oil | Supercomputers, energy storage systems. |

(2)Key Parameters

- Flow rate: 0.5~2 L/min, adjusted based on thermal load.

- Temperature gradient: Inlet-outlet ΔT ≤10℃ to prevent local boiling.

3. Phase Change Cooling

Advantage: Absorb large amounts of heat via latent heat, ideal for transient overloads.

(1)PCM Types

| Material | Phase Transition Temperature | Latent heat capacity | Integration method |

|---|---|---|---|

| Paraffin | 40~80℃ | 150~250 kJ/kg | Embedded in harness sheath layers. |

| Metal Alloys | 100~300℃ | 200~400 kJ/kg | Fins or wraps around harnesses. |

(2)Heat Pipe Technology

- Principle: Evaporation-condensation cycle of working fluid (e.g., water/ammonia).

- Example: 6 mm copper heat pipe, heat transfer >100 W.

4. Hybrid Cooling Systems

Goal: Balance performance and cost by combining multiple cooling methods.

| Combined Solutions | Components & Benefits | Application Cases |

|---|---|---|

| Air + Liquid Cooling | Air cooling at low load, liquid cooling activated at high load. | Hybrid EV harnesses, smart grid systems. |

| PCM + Heat Pipes | PCM absorbs peak heat, heat pipes export residual heat. | 5G base station harnesses, industrial robots. |

▶ Summary

The selection of an active cooling system requires a combination of Heat Load Intensity, Environmental Constraints and Cost-Effectiveness:

Monitoring & Protection

Objective: Prevent harness failure caused by overheating through real-time monitoring and intelligent protection.

1. Real-Time Monitoring

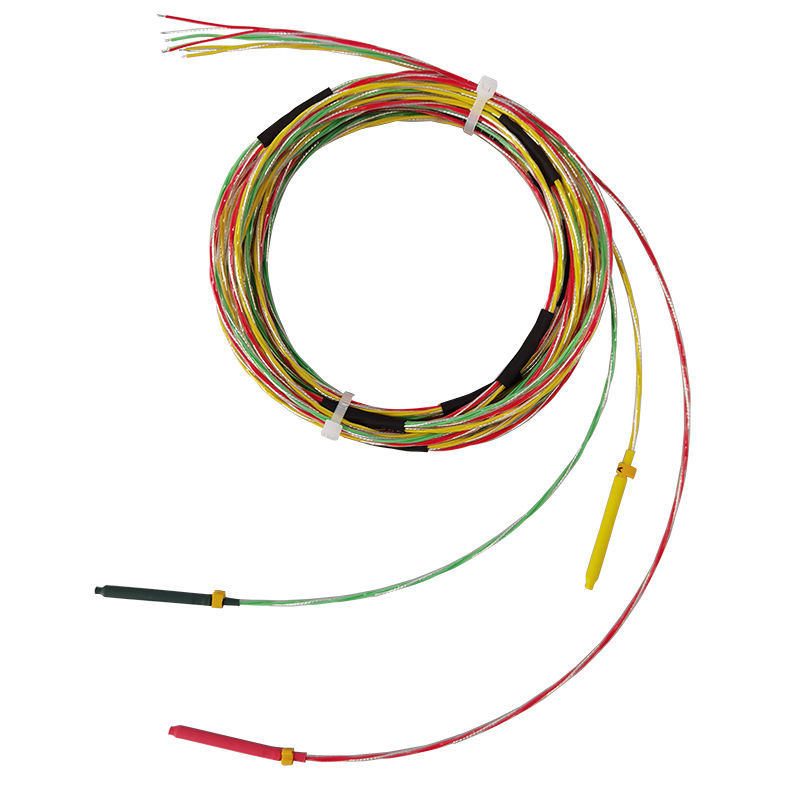

(1)Temperature Sensors

| Type | Principle | Precision | Application Scenarios |

|---|---|---|---|

| Thermocouples | Based on Seebeck effect (temperature difference). | ±1.5℃ | High-temperature harnesses (>300℃). |

| PT100 Sensors | Linear resistance variation (100Ω at 0℃). | ±0.3℃ | Precision systems (e.g., medical devices). |

| Fiber Optic Sensors | Light signals modulated by temperature, EMI-resistant. | ±0.5℃ | High-voltage substations, explosive environments. |

(2)Multi-Parameter Monitoring

- Current/Voltage Monitoring: Hall sensors (±1% accuracy) detect overload currents.

- Thermal Imaging: Infrared cameras (resolution ≤0.05℃) scan hotspots periodically

2. Overload Protection

(1)Smart Circuit Breakers

| Function | Trigger conditions | Response time |

|---|---|---|

| Dual Thresholds (T & I) | T >85℃ or I >150% rated current. | ≤50 ms |

| Auto-Reset | Auto-reconnect after cooling (ΔT <10℃). | 5~10 min |

(2)Fuses & Current Limiters

| Type | Characteristic | Scenario |

|---|---|---|

| Fast-Acting Fuses | Response <1 ms, breaking capacity 10 kA. | Short-circuit protection (e.g., battery harnesses). |

| PTC Resettable Fuses | Resistance spikes during overload, self-resetting. | Consumer electronics, low-voltage automotive harnesses. |

(3)Dynamic Load Management

- Priority Control: Shut down non-critical loads via CAN/PLC.

- Current Balancing: Distribute current among parallel harnesses (<5% deviation).

3. Data Analytics & Alerts

(1)Predictive Maintenance

| Technologies | Data Sources | Early Warning Indicators |

|---|---|---|

| Machine Learning | Historical T, I, and environmental data. | Temperature rise rate >2℃/min or aging index >80%. |

| Digital Twin | 3D harness model + real-time sensor data. | Alert when simulation-actual ΔT >5℃. |

(2)Remote Monitoring Platforms

- Cloud Dashboard: Visualize temperature distribution, load status, and trends.

- Multi-level alarms:

- Level 1 (Yellow): 80% threshold reached, notify operators.

- Level 2 (Red): Threshold exceeded, activate protection.

▶ Summary

The monitoring and protection system builds a closed-loop security system through Real-Time Sensing, Intelligent Decision-Making and Rapid Response. Typical programs include:

- Fiber Optic Sensors + Smart Breakers + Digital Twin

- In-vehicle scenarios:PTC Fuses + CAN-Based Load Management

Maintenance Management

Objective: Extend harness lifespan and sustain cooling performance through systematic maintenance.

1. Scheduled Maintenance Plans

Core principle: Prevent cooling failure caused by aging or contamination.

(1)Scheduled Maintenance Plans

| Maintenance tasks | Frequency | Tools & Methods | Target results |

|---|---|---|---|

| Insulation Inspection | Every 6 months | Visual check + Megger (>100 MΩ). | Prevent leakage and short circuits. |

| Cooling Structure Cleaning | Every 3 months | Compressed air (≤0.3 MPa) or ultrasonic cleaning. | Restore >90% cooling efficiency. |

| Connection Tightening | Annual | Torque wrench (5~10 N·m per specs). | Reduce contact resistance by 10%~20%. |

2. Cleaning & Contamination Control

(1)Dust & Oil Removal

- Dry Cleaning: Anti-static brushes or vacuums for surface dust.

- Wet Cleaning: Isopropyl alcohol (≥99%) for oil stains, avoiding insulation damage.

(1)Anti-Corrosion Measures

| Methods | Scenario | Effect |

|---|---|---|

| Conformal Coating | High humidity/salt spray environments. | Reduce corrosion by 70%~90%. |

| Sealed Terminal Boxes | Chemical or dusty areas. | >95% contaminant blockage. |

3. Load Management & Upgrades

(1)Load Balancing Strategies

- Dynamic Allocation: Adjust loads based on real-time temperature (<5% deviation).

- Capacity Upgrade: Replace with larger cross-section cables (e.g., 4→6 mm²).

(2)Overload History Analysis

| Parameters | Analysis Tools | Optimization Actions |

|---|---|---|

| Peak Current Logs | Data loggers (≥1 kHz sampling). | Adjust breaker thresholds or add redundancy. |

| Temperature Rise Curves | Thermal simulation software. | Optimize cooling structures or boost cooling power. |

▶ Summary

Maintenance management achieves sustainable cooling effectiveness through Preventive Maintenance, Data-Driven Decisions and Capacity Building. Typical Scenario Applications:

- Quarterly Cleaning + Load Analysis + ANSYS Simulation

- In-vehicle scenarios:Annual Tightening + Dynamic Load Allocation

Aucun commentaire à afficher.

Laisser un commentaire