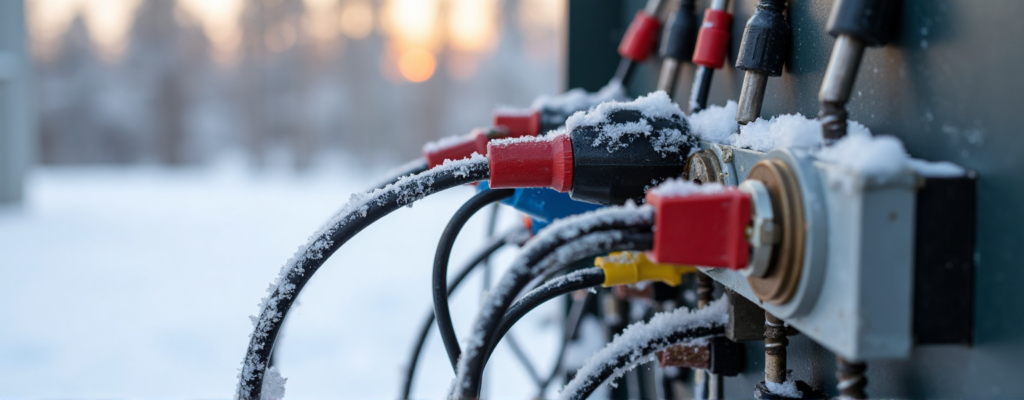

Anti-Freeze Cracking Solution for Battery Pack Wiring Harnesses at -30℃ in Winter

Core Concept: The core of preventing freeze cracking lies in material low-temperature toughness, structural design to avoid stress concentration, process control to ensure quality, and environmental adaptability design.

Material Selection and Optimization (Foundation of Low-Temperature Toughness)

Cable Insulation and Sheath Materials:

Case: A pure electric bus operating in Northeast China frequently experienced brittle cracking of the insulation layer on low-voltage signal wires inside the battery pack during winter, leading to signal loss.

Solutions:

Select Specialized Cold-Resistant Materials: Switch from ordinary PVC materials to specialized cold-resistant TPE, TPU, silicone rubber, or modified XLPO. For example, use silicone rubber insulated cables rated for -55°C or even -70°C.

Verify Low-Temperature Performance: Require suppliers to provide test reports for low-temperature bending and impact (e.g., UL 1581 VW-1 Cold Bend, ISO 6722 Cold Impact Test) to ensure no cracking or powdering occurs at -40°C or lower.

Focus on Plasticizer Stability: Ensure the plasticizers used in the materials are resistant to migration and volatilization at low temperatures, preventing the material from becoming hard and brittle. Select cold-resistant plasticizer formulations.

Connector Seals/Gaskets:

Case: An energy storage battery pack in the severely cold Northwest China region experienced hardened and inelastic seals after connector mating/unmating, leading to seal failure, moisture ingress, and subsequent corrosion.

Solutions:

Select Fluororubber or Special Silicone: Replace ordinary NBR rubber with fluororubber or cold-resistant silicone rubber seals/potting compounds. Fluororubber maintains good elasticity and low compression set at extremely low temperatures.

Verify Compression Set: Require suppliers to provide compression set test data (e.g., ASTM D395) at low temperatures (e.g., -40°C) to ensure effective sealing remains at low temperatures.

Consider Low-Temperature Mating/Unmating Force: Evaluate if mating/unmating forces increase significantly at low temperatures to avoid operational difficulties or connector damage.

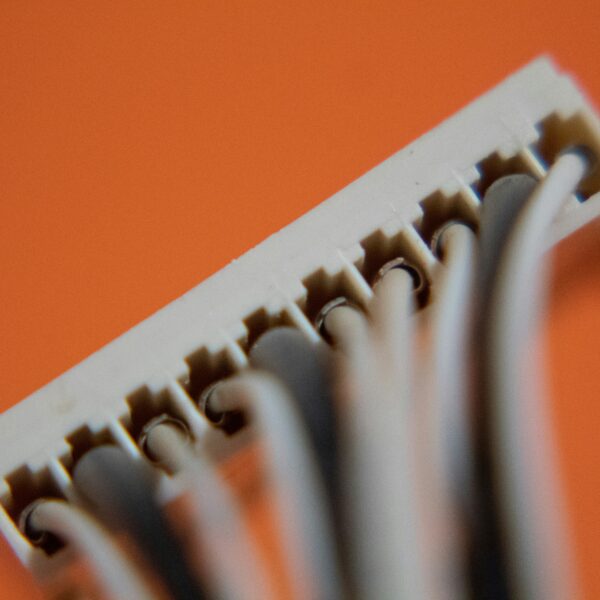

Harness Conduit/Protective Sleeving:

Case: Conduit for wiring harnesses inside a battery pack became brittle at -30°C, and vehicle vibration led to conduit fracture and wire abrasion.

Solutions:

Select PP or PA-Based Cold-Resistant Conduit: Avoid using ordinary PVC conduit. Use modified cold-resistant PP (Polypropylene) or PA (Nylon) based conduit, such as PA12, which has better low-temperature toughness than PA6.

Verify Low-Temperature Bending/Impact: Perform low-temperature bending tests (e.g., ISO 527) and falling weight impact tests (e.g., ISO 179) to ensure no cracking occurs at the target low temperature.

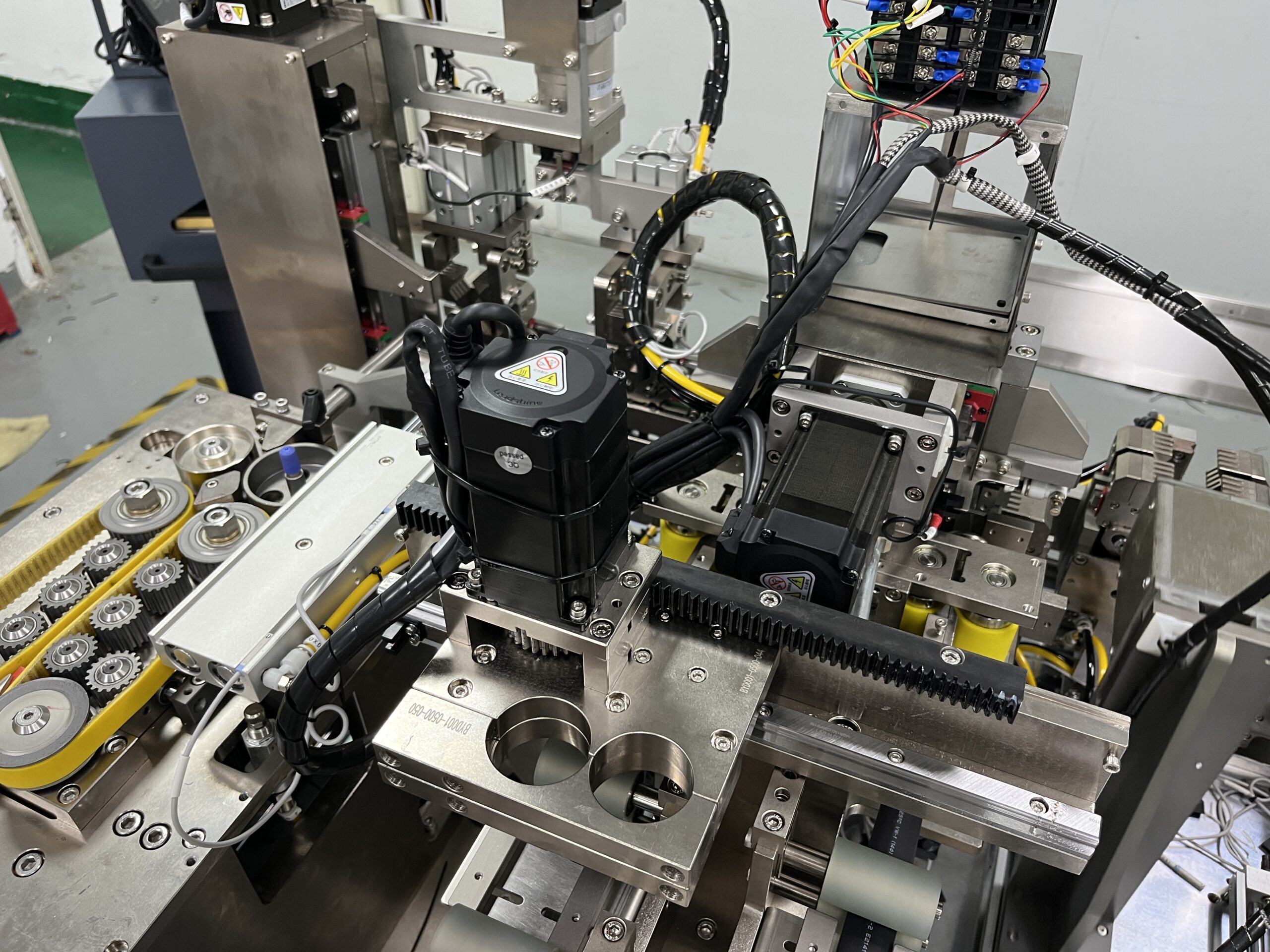

Structure and Layout Design (Avoiding Stress Concentration and Excessive Strain)

Harness Routing and Bend Radius:

Case: A harness inside a battery pack was bent at a sharp angle near a fixing point; during cold winter temperatures, cracks first appeared on the outer side of the insulation at this bend.

Solutions:

Increase Minimum Bend Radius: Strictly adhere to the cable manufacturer’s specified minimum bend radius requirements (typically 5-8 times the cable diameter or more). Further increase this radius for extreme low-temperature environments (e.g., to 8-12 times), especially near fixing points and connector roots.

Optimize Routing Path: Avoid sharp bends and acute angles. Use smooth, curved transitions wherever possible. Utilize wire ducts or guides to direct harness routing.

Avoid “S” Bends: Minimize the number and severity of reverse bends.

Fixing and Support:

Case: A long section of harness, under contraction in cold temperatures, sagged and swung excessively due to vibration because fixing points were too sparse and spaced too far apart, causing excessive stress and cracking at the root of the fixing points.

Solutions:

Increase Fixing Point Density: In low-temperature environments, reduce the spacing between adjacent fixing points (denser than room temperature design) to prevent excessive displacement and stress caused by contraction or vibration. Use cable ties, clips, saddles, etc.

Use Flexible Fixing/Cushioning: At fixing points, use clips with rubber grommets, wrap with felt tape, or add conduit to provide cushioning and avoid hard contact and stress concentration.

Slack Design: Provide sufficient “service loops” or slack at connector entry points and harness bends to allow for contraction/expansion at low temperatures, avoiding pulling on connectors or straining the harness.

Connector Root Protection:

Case: The harness behind the connector (at the wire tail) frequently experienced insulation breakage under vibration at low temperatures.

Solutions:

Enhance Strain Relief: Use molded strain relief boots or heat shrink tubing with hot melt adhesive to reinforce, secure, and protect the connector wire tail, creating a smooth transition and distributing stress.

Avoid Sharp Bends at Root: Ensure a sufficient straight section of harness (>50mm) exits the connector before any bend is introduced.

Manufacturing Process and Quality Control (Eliminating Potential Defects)

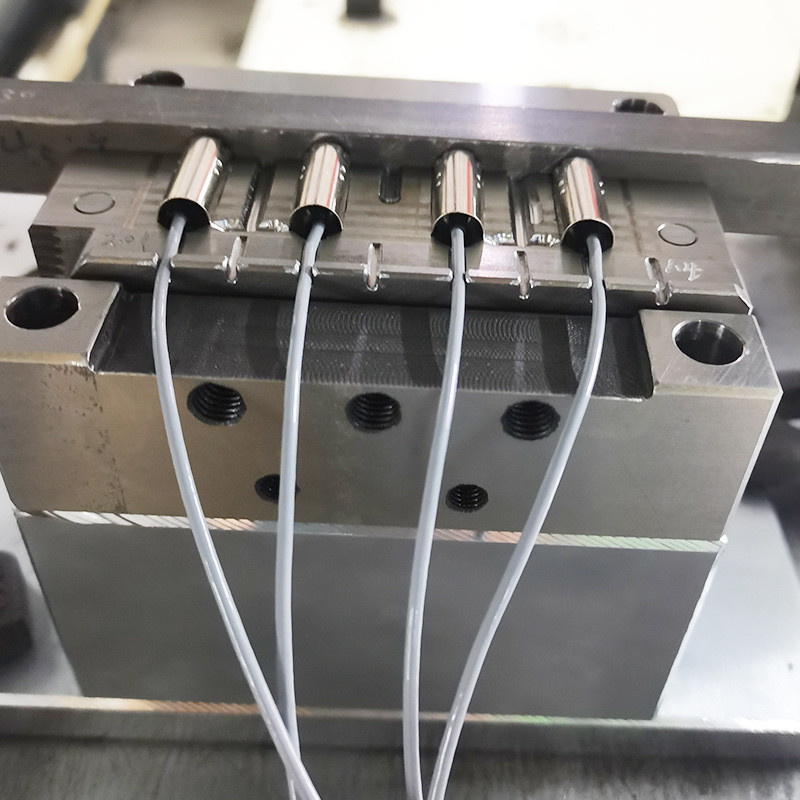

Injection Molding and Molding Process Control:

Case: Within the same batch of harnesses, some connector molded boots cracked during low-temperature testing. Analysis revealed excessive internal stress caused by improper molding parameters.

Solutions:

Optimize Process Parameters: Strictly control injection temperature, pressure, holding time, and cooling rate to avoid internal stress caused by rapid cooling or uneven pressure. Mold design adjustments (e.g., gate location) may be needed.

Material Pre-treatment: Ensure raw materials are thoroughly dried to prevent moisture from freezing, expanding, and causing micro-cracks at low temperatures.

Stress Relief: Perform annealing on molded parts (if applicable) to relieve internal stresses.

Crimping and Termination Quality:

Case: Insulation near crimp points cracked at low temperatures. Root cause analysis traced it to crimp tool wear leading to over-crimping and excessive deformation.

Solutions:

Ensure Crimp Quality: Use qualified and well-maintained crimping tools with regular pull force calibration. Ensure crimp shape meets standards, is free of burrs, over-crimping, or under-crimping. Over-crimping damages conductor and insulation.

Avoid Insulation in Crimp: The crimp zone should only contact the conductor. Avoid crimping into the insulation layer, as this creates a stress concentration point at low temperatures.

Assembly Process Protection:

Case: Insulation near crimp points cracked at low temperatures. Root cause analysis traced it to crimp tool wear leading to over-crimping and excessive deformation.

Solutions:

Standardize Low-Temperature Assembly Operations: Establish strict assembly procedures prohibiting excessive bending, stretching, or impacting of harnesses at low temperatures. Ensure assembly environment temperature or pre-warm harnesses (e.g., using local warm air blowers).

Enhance Employee Training: Emphasize the fragility of harnesses at low temperatures and the correct handling methods.

Environmental Adaptability Design and Verification (Real-World Testing)

Low-Temperature Thermal Cycling and Shock Testing:

Case: Harnesses passing lab static cold soak tests at -30°C developed cracks after experiencing multiple “cold start-operation-shutdown” cycles in real vehicles.

Solutions:

Strengthen Environmental Validation: Conduct more stringent temperature cycling tests (e.g., -40°C to +85°C, >100 cycles) and temperature shock tests (e.g., -40°C ←→ +25°C, rapid transition, >50 cycles). These better expose material fatigue and stress issues than single-point static cold tests.

Combine with Vibration Testing: Perform combined vibration testing (e.g., random vibration + temperature) in low-temperature environments to simulate real-world driving conditions.

Real-World Monitoring: Deploy prototype vehicles or energy storage systems in severely cold regions for long-term winter road testing or field operation monitoring to collect harness condition data.

Localized Heating and Insulation (Special/Remedial Measures):

Case: For extremely cold regions (e.g., below -40°C) or specific critical harnesses, relying solely on materials and design may be insufficient.

Solutions:

Key Area Heating: Integrate low-power heating films or heating wires near vulnerable harness points inside the battery pack (e.g., connector roots, sharp bends), controlled by the BMS for brief heating before cold start or during operation.

Selective Insulation: Wrap the main harness trunk or specific areas inside the battery pack with low-temperature resistant flexible insulation materials (e.g., aerogel blankets, special foams) to slow down rapid temperature drops. Fire resistance/retardancy and heat dissipation requirements must be considered.

Battery Pack Preheating Strategy: Utilize the battery pack’s own heating system (PTC or liquid thermal) or power from charging piles to remotely initiate battery pack preheating before vehicle use, raising the entire pack (including harnesses) to a safe temperature range (e.g., >-20°C) before operation.

Key Practical Points Summary:

· Material is the Foundation: Must use verified, specialized materials with excellent low-temperature toughness and cold resistance ratings (silicone, TPU, fluororubber, etc.).

· Design Eliminates Stress: Maximize avoidance of stress concentration through design means like increasing bend radius, optimizing routing, adding fixing points, and root protection.

· Process Controls Risk: Strictly control key process parameters like injection molding and crimping to eliminate internal stresses and potential damage during manufacturing.

· Testing Simulates Reality: Employ rigorous tests like temperature cycling, thermal shock, and combined vibration to simulate the harshest real-world operating conditions.

· Special Environments Require Special Measures: In extreme conditions, consider localized heating or insulation as supplementary solutions.

· Full Lifecycle Consideration: Every stage – design, material selection, manufacturing, assembly, and test validation – must account for the impact of the extreme -30°C low temperature.

表示できるコメントはありません。

Leave a Comment